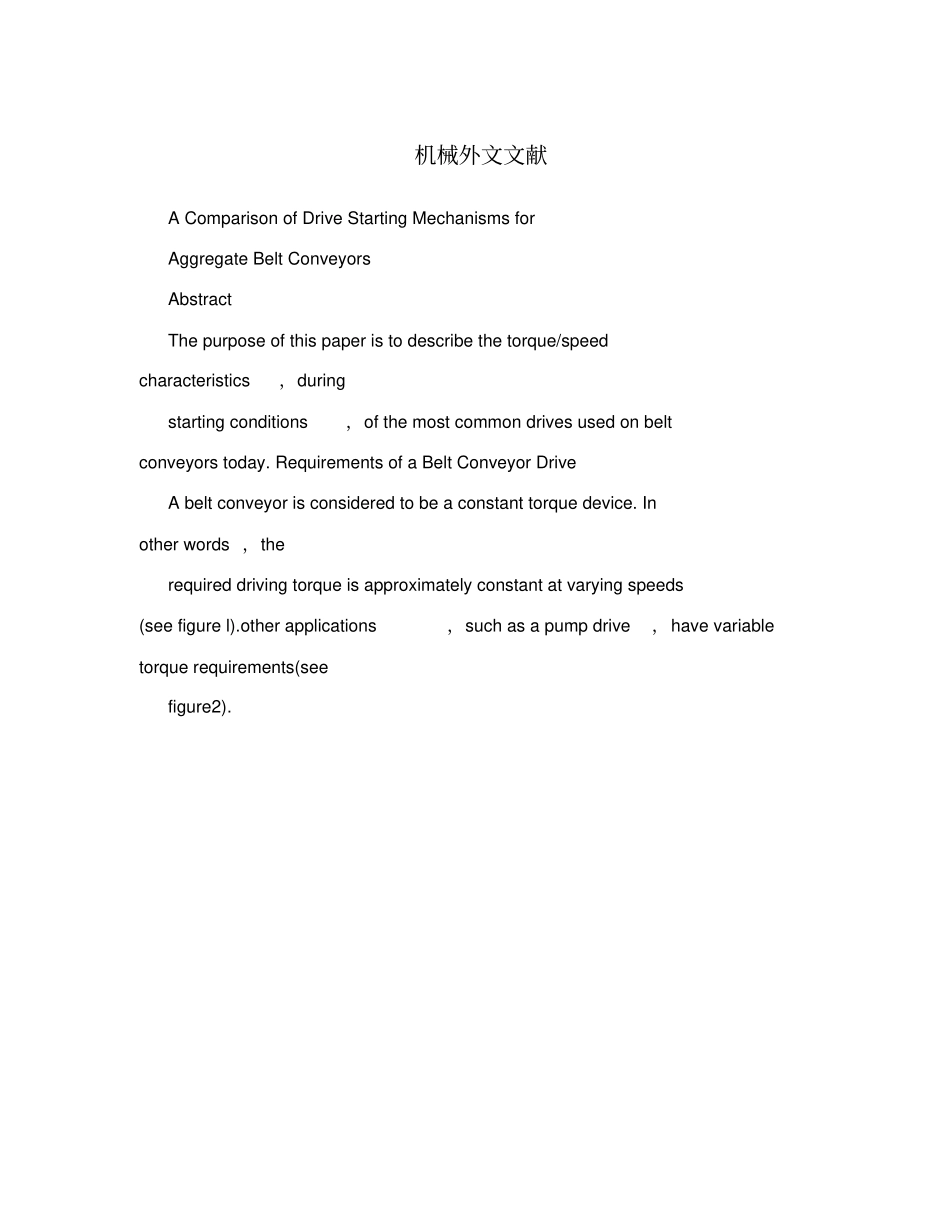

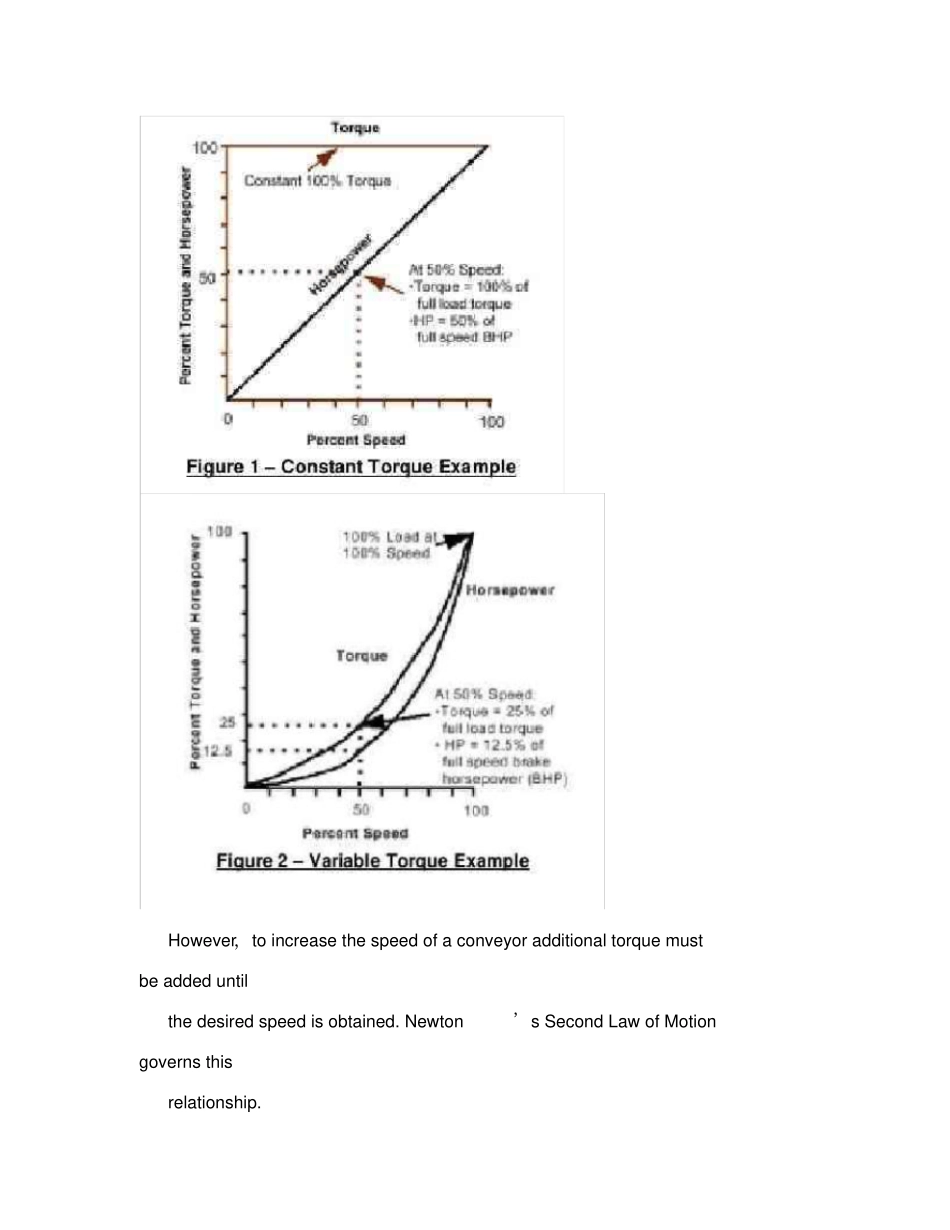

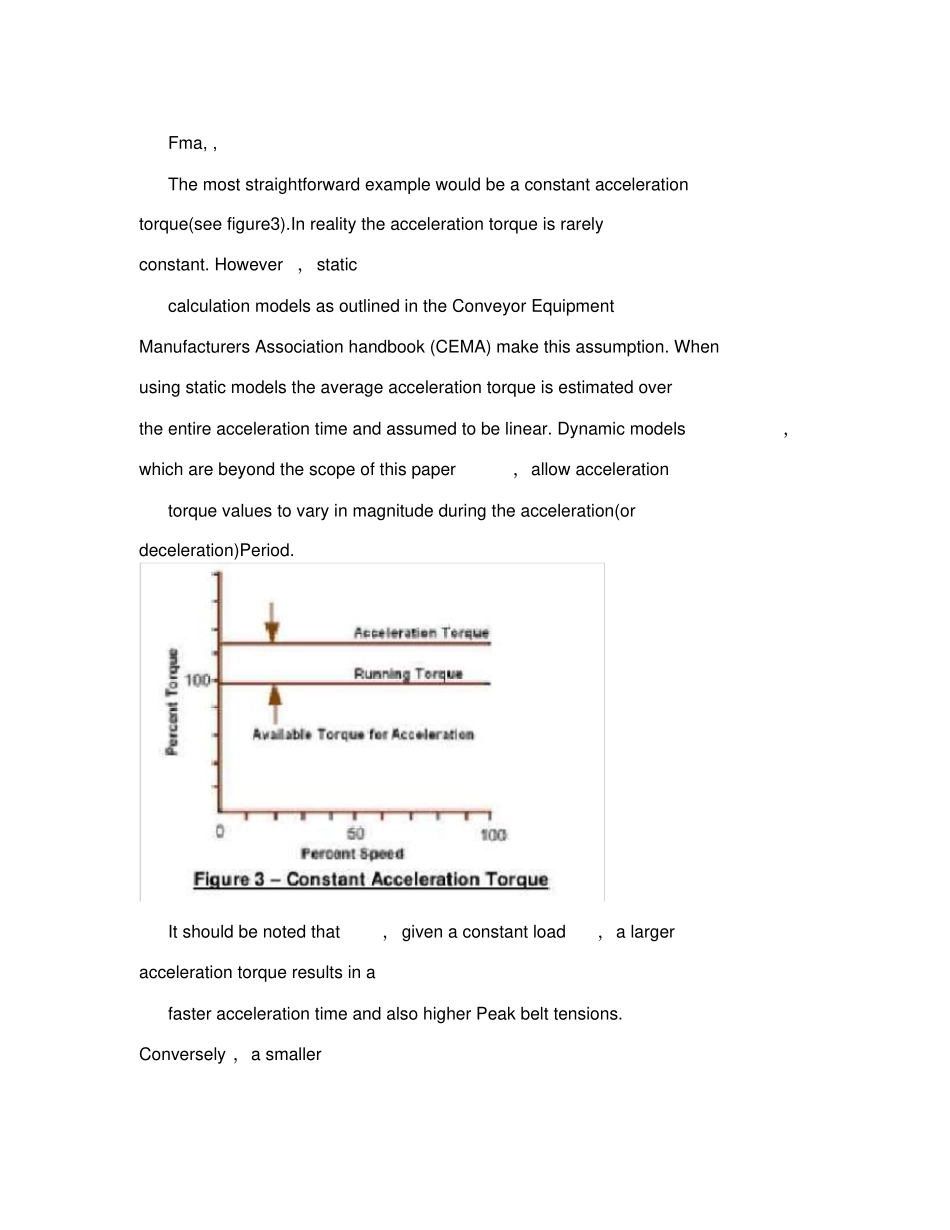

机械外文文献A Comparison of Drive Starting Mechanisms for Aggregate Belt Conveyors Abstract The purpose of this paper is to describe the torque/speed characteristics,during starting conditions,of the most common drives used on belt conveyors today. Requirements of a Belt Conveyor Drive A belt conveyor is considered to be a constant torque device. In other words ,the required driving torque is approximately constant at varying speeds (see figure l).other applications,such as a pump drive,have variable torque requirements(see figure2). However,to increase the speed of a conveyor additional torque must be added until the desired speed is obtained. Newton’s Second Law of Motion governs this relationship. Fma, , The most straightforward example would be a constant acceleration torque(see figure3).In reality the acceleration torque is rarely constant. However,static calculation models as outlined in the Conveyor Equipment Manufacturers Association handbook (CEMA) make this assumption. When using static models the average acceleration torque is estimated over the entire acceleration time and assumed to be linear. Dynamic models,which are beyond the scope of this paper,allow acceleration torque values to vary in magnitude during the acceleration(or deceleration)Period. It should be noted that,given a constant load,a larger acceleration torque results in a faster acceleration time and also higher Peak belt tensions. Conversely ,a smaller acceleration torque results in a longer start time and smaller Peak belt tensions. Across-The-Line AC Motor Start Technically this is the simplest type of drive used on a belt conveyor. In this drive type an AC squirrel cage induction motor is started by simply throwing the contact...