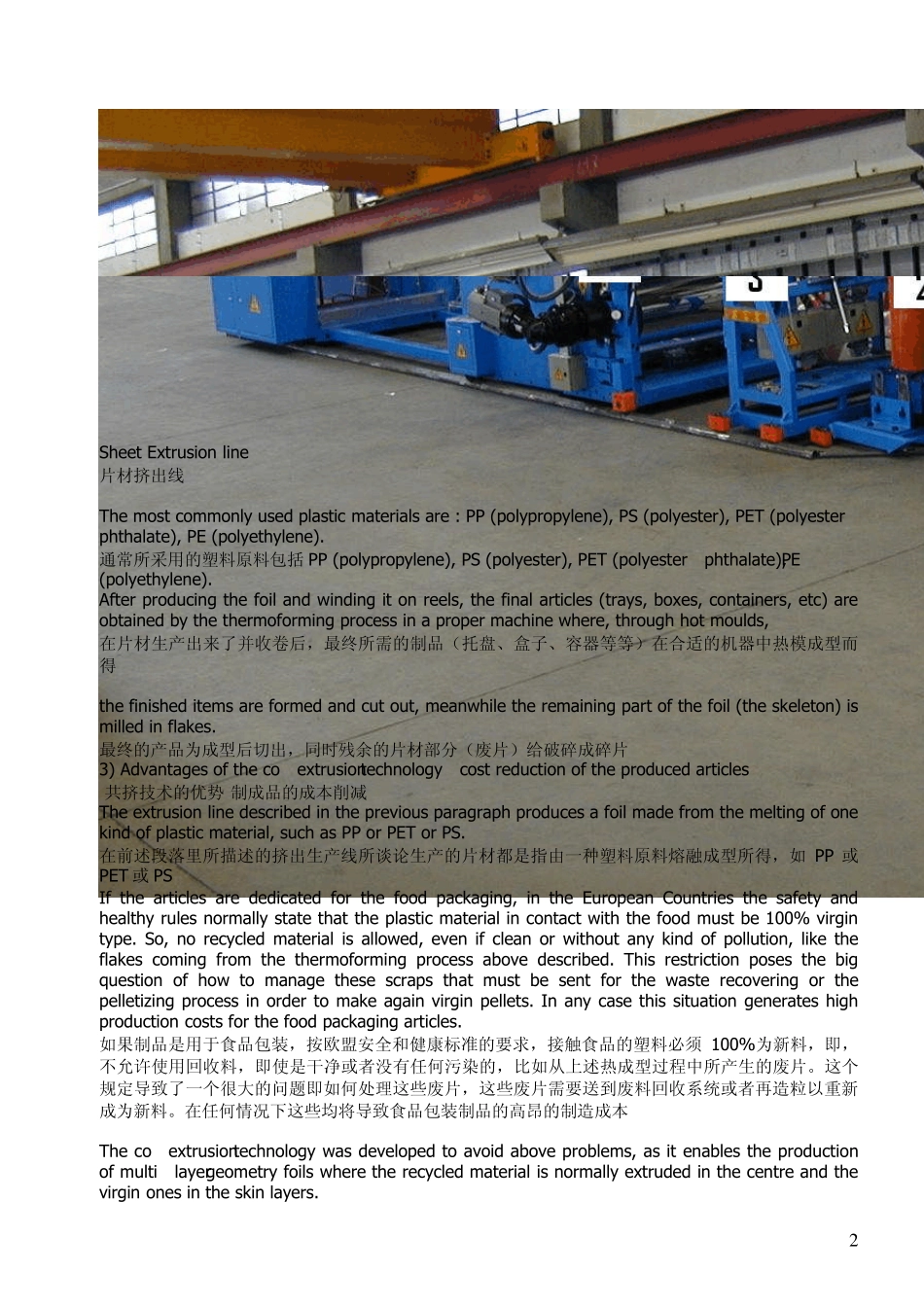

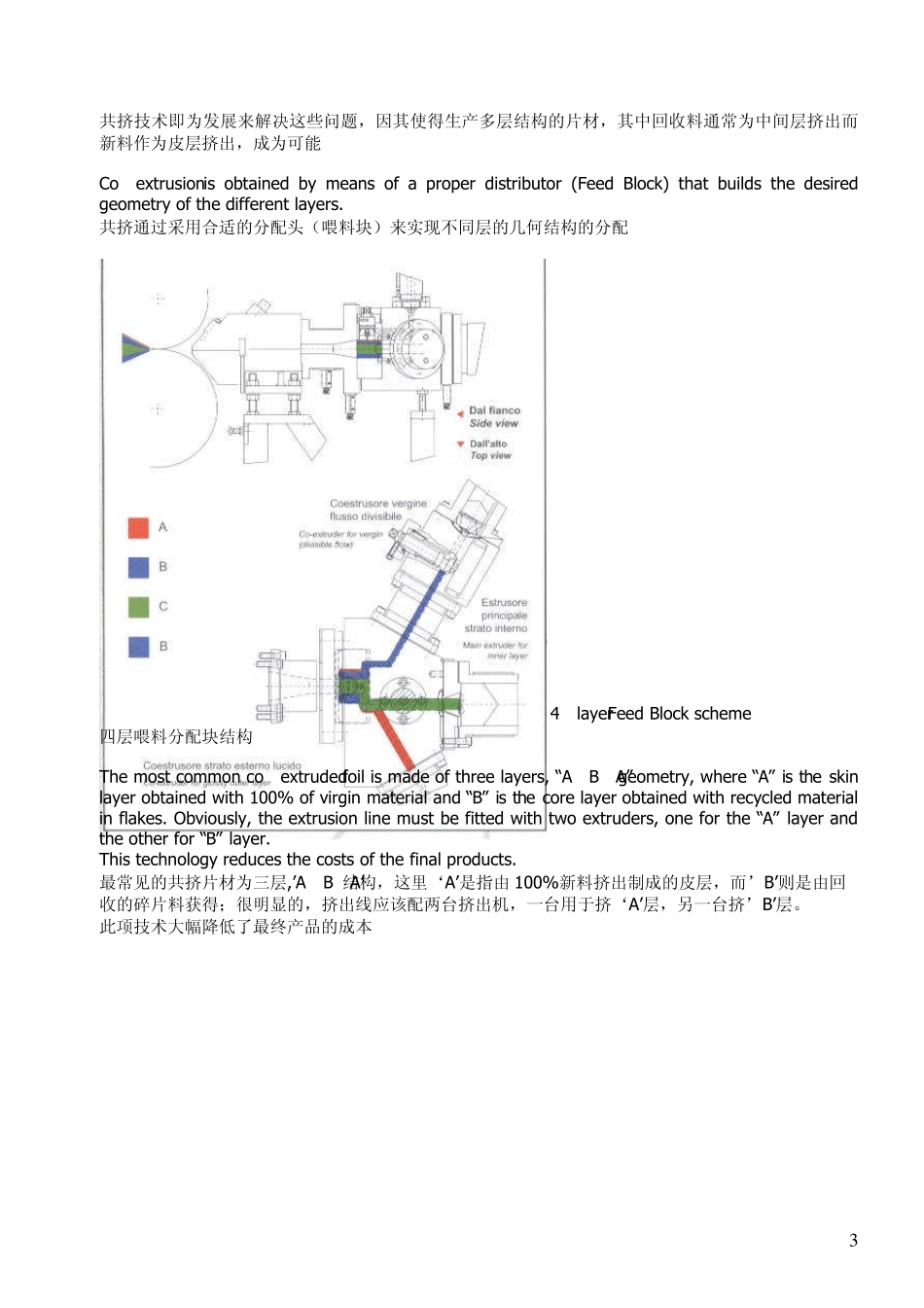

12Sheet Extrusion line片材挤出线The most commonly used plastic materials are : PP (polypropylene), PS (polyester), PET (polyester-phthalate), PE (polyethylene).通常所采用的塑料原料包括PP (polypropylene), PS (polyester), PET (polyester-phthalate),PE(polyethylene).After producing the foil and winding it on reels, the final articles (trays, boxes, containers, etc) areobtained by the thermoforming process in a proper machine where, through hot moulds,在片材生产出来了并收卷后,最终所需的制品(托盘、盒子、容器等等)在合适的机器中热模成型而得the finished items are formed and cut out, meanwhile the remaining part of the foil (the skeleton) ismilled in flakes.最终的产品为成型后切出,同时残余的片材部分(废片)给破碎成碎片3) Advantages of the co-extrusiontechnology -cost reduction of the produced articles共挤技术的优势-制成品的成本削减The extrusion line described in the previous paragraph produces a foil made from the melting of onekind of plastic material, such as PP or PET or PS.在前述段落里所描述的挤出生产线所谈论生产的片材都是指由一种塑料原料熔融成型所得,如 PP 或PET 或 PSIf the articles are dedicated for the food packaging, in the European Countries the safety andhealthy rules normally state that the plastic material in contact with the food must be 100% virgintype. So, no recycled material is allowed, even if clean or without any kind of pollution, like theflakes coming from the thermoforming process above described. This restriction poses the bigquestion of how to manage these scraps that must be sent for the waste recovering or thepelletizing process in order to make again virgin pellets. In any case this situation generates highproduction costs for the food packaging articles.如果制品是用于食品包装,按欧盟安全和健康标准的要求,接触食品的塑料必须 100%为新料,即,...