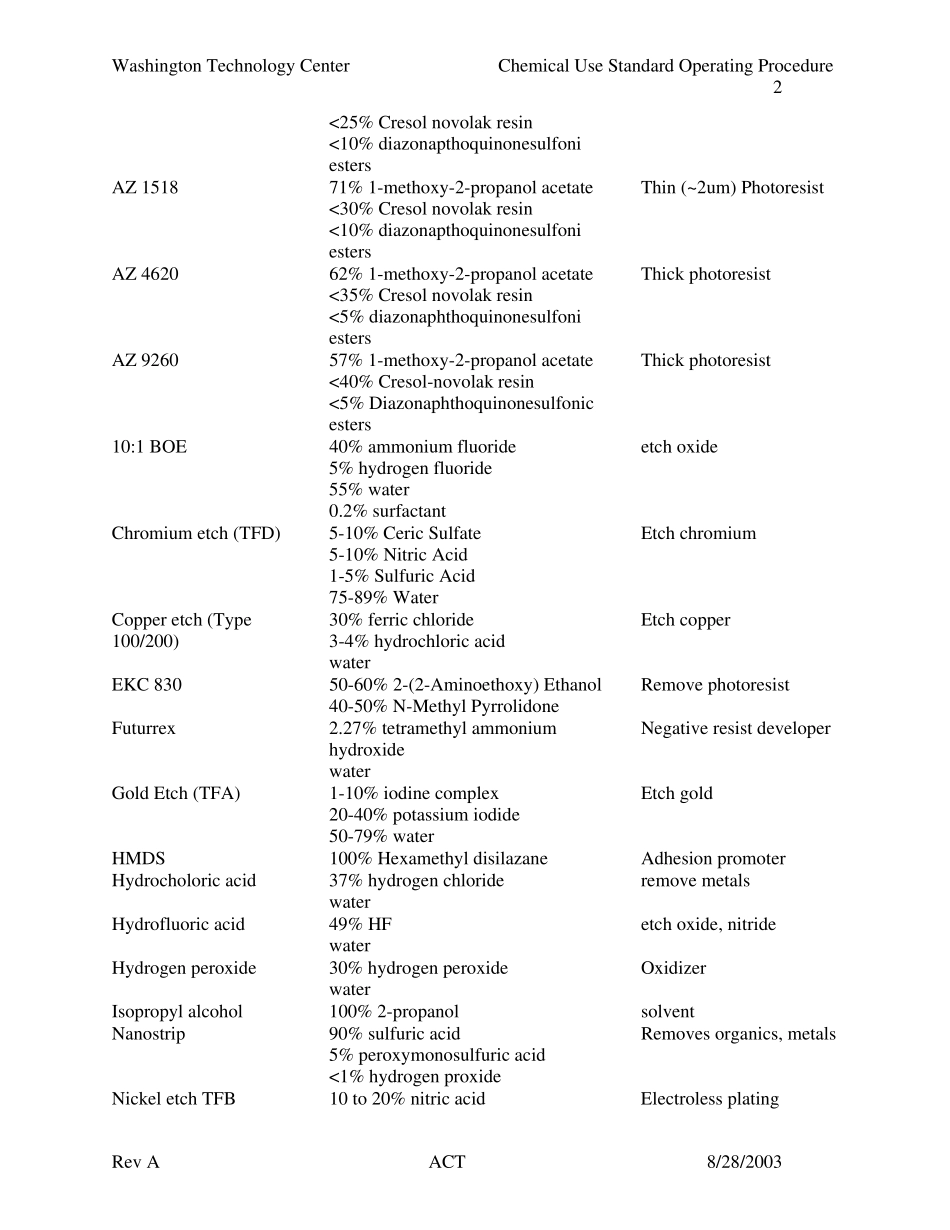

Washington Technology Center Chemical Use Standard Operating Procedure 1 Rev A ACT 8/28/2003 Chemical Use Standard Operating Procedu re 1.0 Pu rpose This document provides detailed instructions on chemical use at the wet benches at Washington Technology Center. 2.0 Equ ipment and Materials 2.1 Equ ipment 2.1.1 Wet bench 2.1.2 Spin rinse dryer 2.1.3 Face shield 2.1.4 Apron 2.1.5 Chemical gloves 2.1.6 Timer 2.1.7 Tweezers 2.1.8 Teflon cassettes 2.1.9 Teflon cassette handles 2.1.10 Teflon single wafer holders 2.2 Chemicals The chemicals available in the lab are as follows Name Composition Purpose Acetic acid 100% acetic acid Wafer clean Acetone 99-100% acetone Solvent Aluminum etch 71-73% Phosphoric acid 5-15% water 9-11% nitric acid 1-3% acetic acid Etch aluminum Ammonium fluoride 40% ammonium fluoride 60% water Oxide etch Ammonium hydroxide 29% ammonium hydroxide water Wafer clean AZ300T 4% Tetramethylammonium hydroxide 41% N-methylpyrrolidone, NMP, 1-methyl-2-pyrrolidinone 55% Propylene glycol, 1, 2-propane-diol remove photoresist AZ 351 <10% sodium borates >90% water Developer for 1512 and 1518 AZ 400K <15% Potassium borates >85% water Developer for 4620 and 9260 AZ 1512 75% 1-methoxy-2-propanol acetate Thin Photoresist Washington Technology Center Chemical Use Standard Operating Procedure 2 Rev A ACT 8/28/2003 <25% Cresol novolak resin <10% diazonapthoquinonesulfoni esters AZ 1518 71% 1-methoxy-2-propanol acetate <30% Cresol novolak resin <10% diazonapthoquinonesulfoni esters Thin (~2um) Photoresist AZ 4620 62% 1-methoxy-2-propanol acetate <35% Cresol novolak resin <5% diazonaphthoquinonesulfoni esters Thick photoresist AZ 9260 57% 1-methoxy-2-propanol acetate <40% Cresol-novolak resin <5% Diazonaphthoquinonesulfonic esters T...