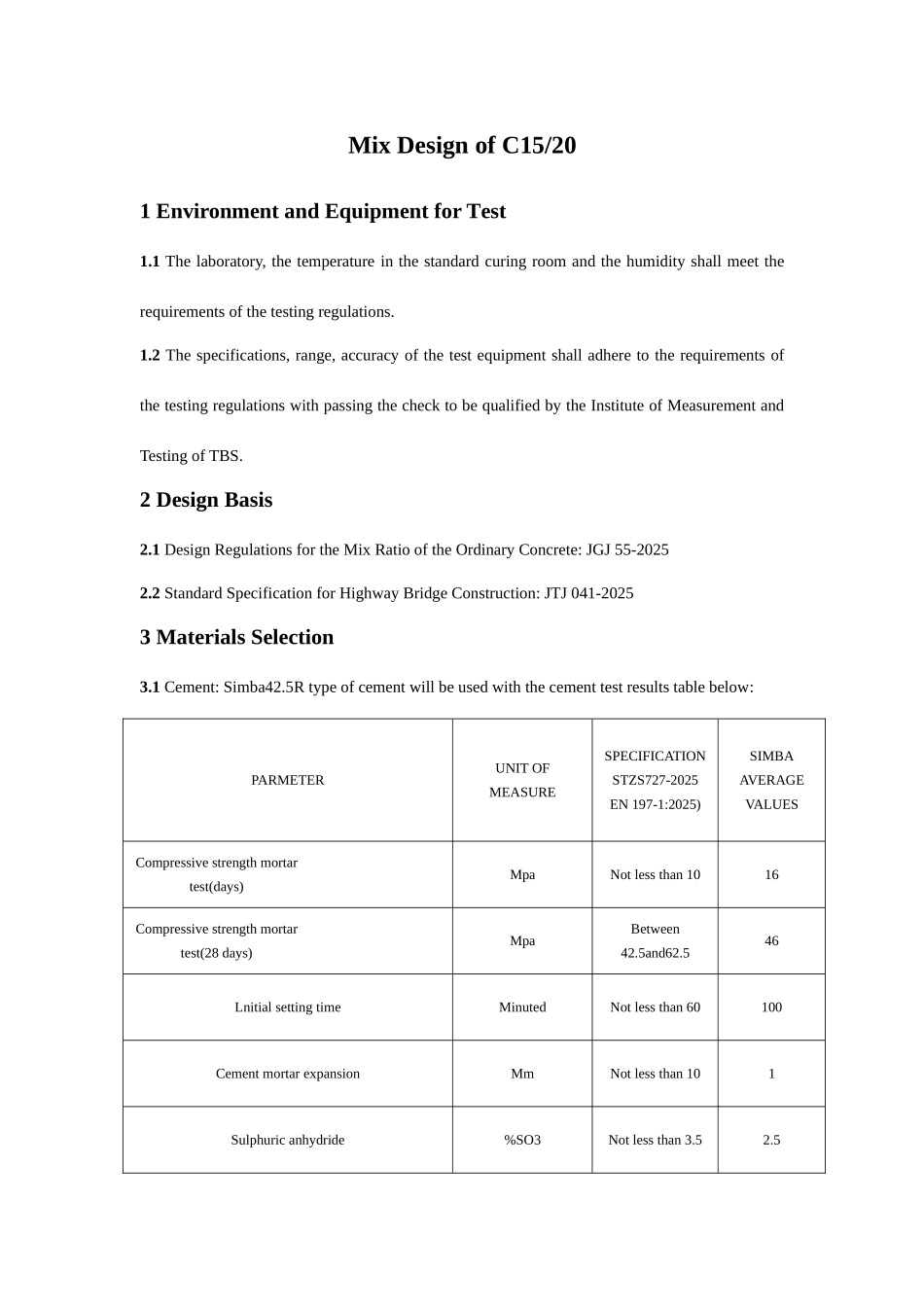

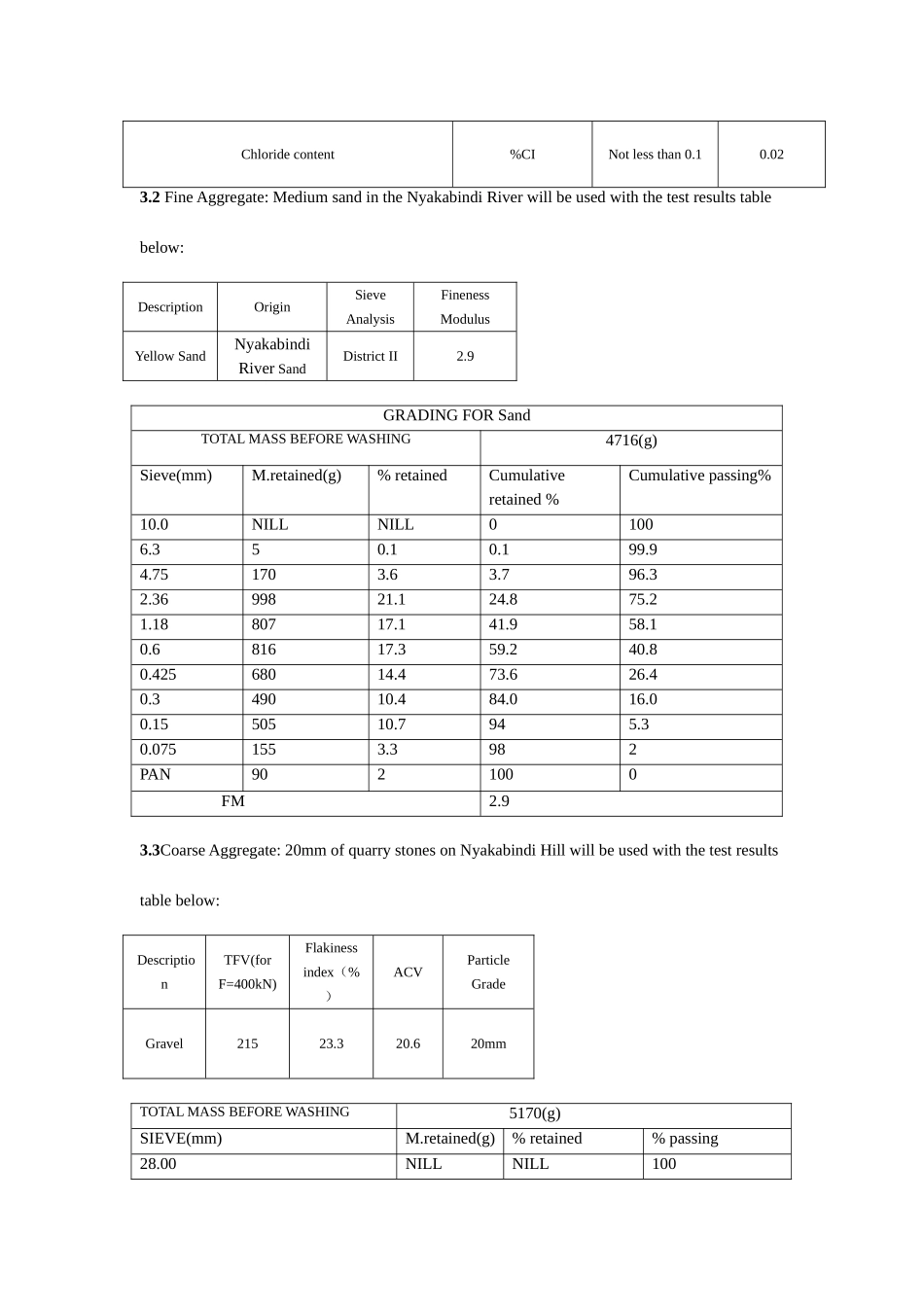

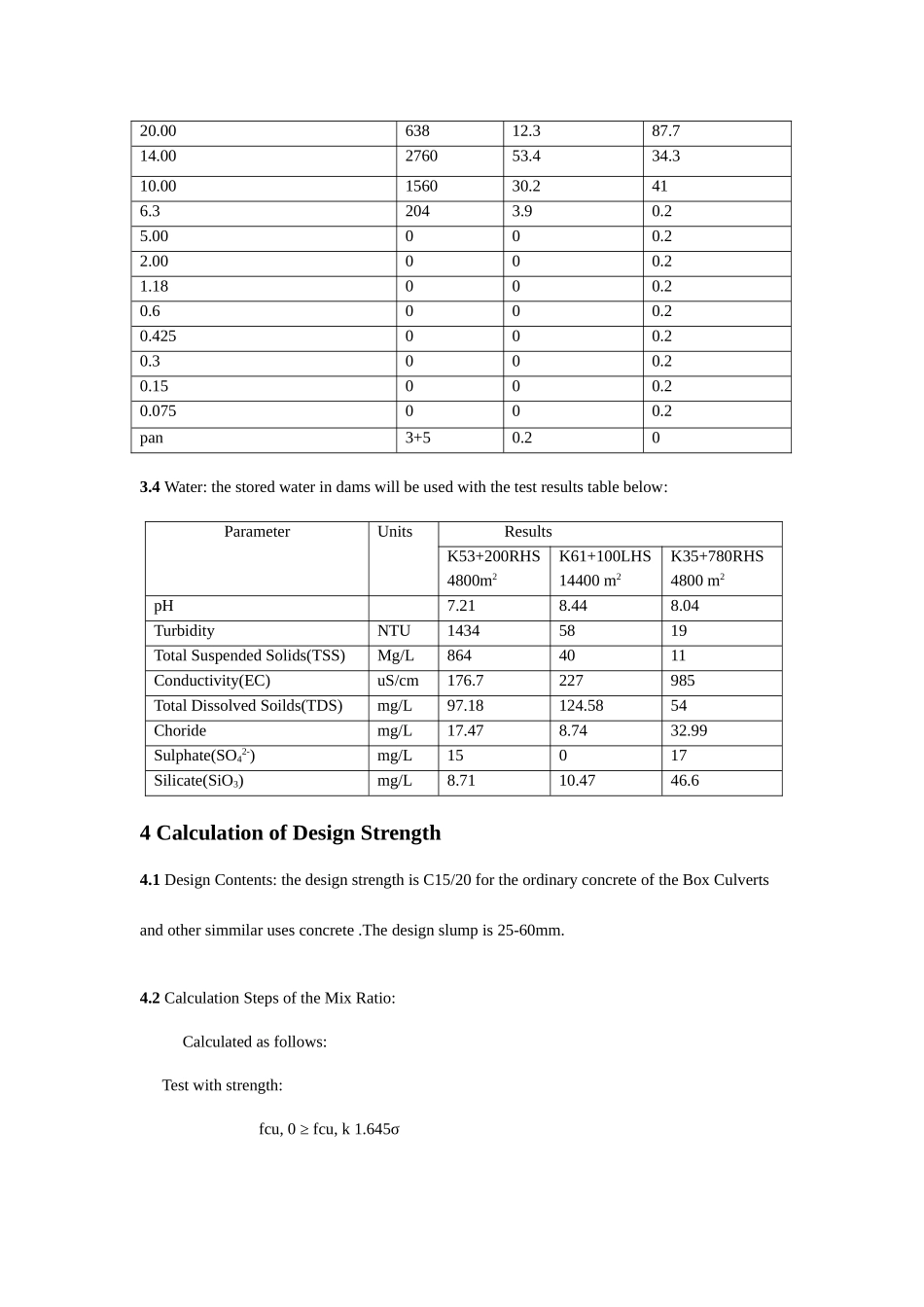

Mix Design of C15/20 1 Environment and Equipment for Test1.1 The laboratory, the temperature in the standard curing room and the humidity shall meet the requirements of the testing regulations.1.2 The specifications, range, accuracy of the test equipment shall adhere to the requirements of the testing regulations with passing the check to be qualified by the Institute of Measurement and Testing of TBS.2 Design Basis2.1 Design Regulations for the Mix Ratio of the Ordinary Concrete: JGJ 55-20252.2 Standard Specification for Highway Bridge Construction: JTJ 041-20253 Materials Selection3.1 Cement: Simba42.5R type of cement will be used with the cement test results table below:PARMETERUNIT OF MEASURESPECIFICATIONSTZS727-2025EN 197-1:2025)SIMBAAVERAGE VALUESCompressive strength mortar test(days)MpaNot less than 1016Compressive strength mortar test(28 days)MpaBetween 42.5and62.546Lnitial setting timeMinutedNot less than 60100Cement mortar expansionMmNot less than 101Sulphuric anhydride%SO3Not less than 3.52.5Chloride content%CINot less than 0.10.023.2 Fine Aggregate: Medium sand in the Nyakabindi River will be used with the test results table below:DescriptionOriginSieve AnalysisFineness ModulusYellow SandNyakabindi River Sand District II2.9GRADING FOR SandTOTAL MASS BEFORE WASHING4716(g)Sieve(mm)M.retained(g)% retainedCumulative retained %Cumulative passing%10.0NILLNILL01006.350.10.199.94.751703.63.796.32.3699821.124.875.21.1880717.141.958.10.681617.359.240.80.42568014.473.626.40.349010.484.016.00.1550510.7945.30.0751553.3982PAN9021000FM2.93.3Coarse Aggregate: 20mm of quarry stones on Nyakabindi Hill will be used with the test results table below: DescriptionTFV(for F=400kN)Flakiness index(%)ACVParticle GradeGravel21523.320.620mmTOTAL MASS BEFORE WASHING5170(g)SIEVE(mm)M.retaine...