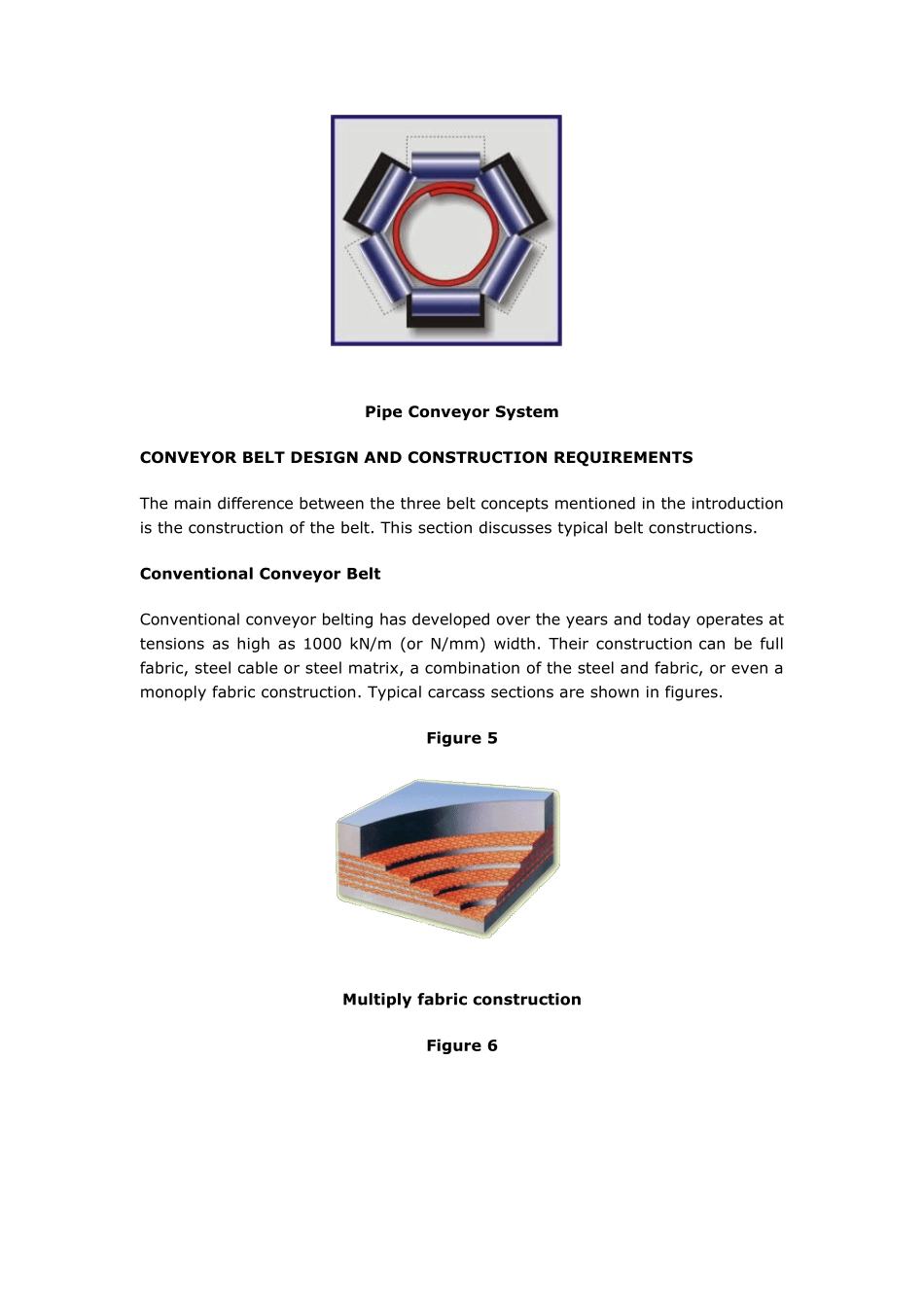

Modern Belt Conveyor Systems G. Lodewijks Faculty of Design, Engineering and Production, Delft University of Technology, the Netherlands INTRODUCTION Belt conveyors have been used for over 150 years. The concept of conveying bulk solid materials by belt, however, has not really changed. Most research has been focused on the improvement of conveyor components and on the optimization of the belt’s reinforcement material and rubber compounds. Today however, one can differentiate between open and closed conveyor systems. In conventional open belt conveyor systems the belt is troughed and the bulk solid material is in direct contact with the air, (although the total conveyor may be enclosed). In closed conveyor systems, the belt contains the bulk material, thus eliminating the risk of dust contamination. Figure 1 New pipe conveyor system incorporating triangular gantry concept This paper will discuss the state-of-the-art in closed belt conveyor system design, and will highlight the most important differences between open and closed belt conveyor systems. The following topics will be discussed: conveyor belt design and construction requirements, conveyor suitability, conveyor loading and unloading procedures and systems, conveyor geometry in particular the design of horizontal and vertical curves, conveyor structure design, conveyor drive systems, in particular the energy consumption, environmental impact of belt conveyors. The characteristics of a conventional belt conveyor will be compared with those of both the pouched and pipe conveyor to discuss the above mentioned topics. The figures 1, 2, & 3 show the basic construction of the two closed belt conveyor concepts. Although the figures 1 an...