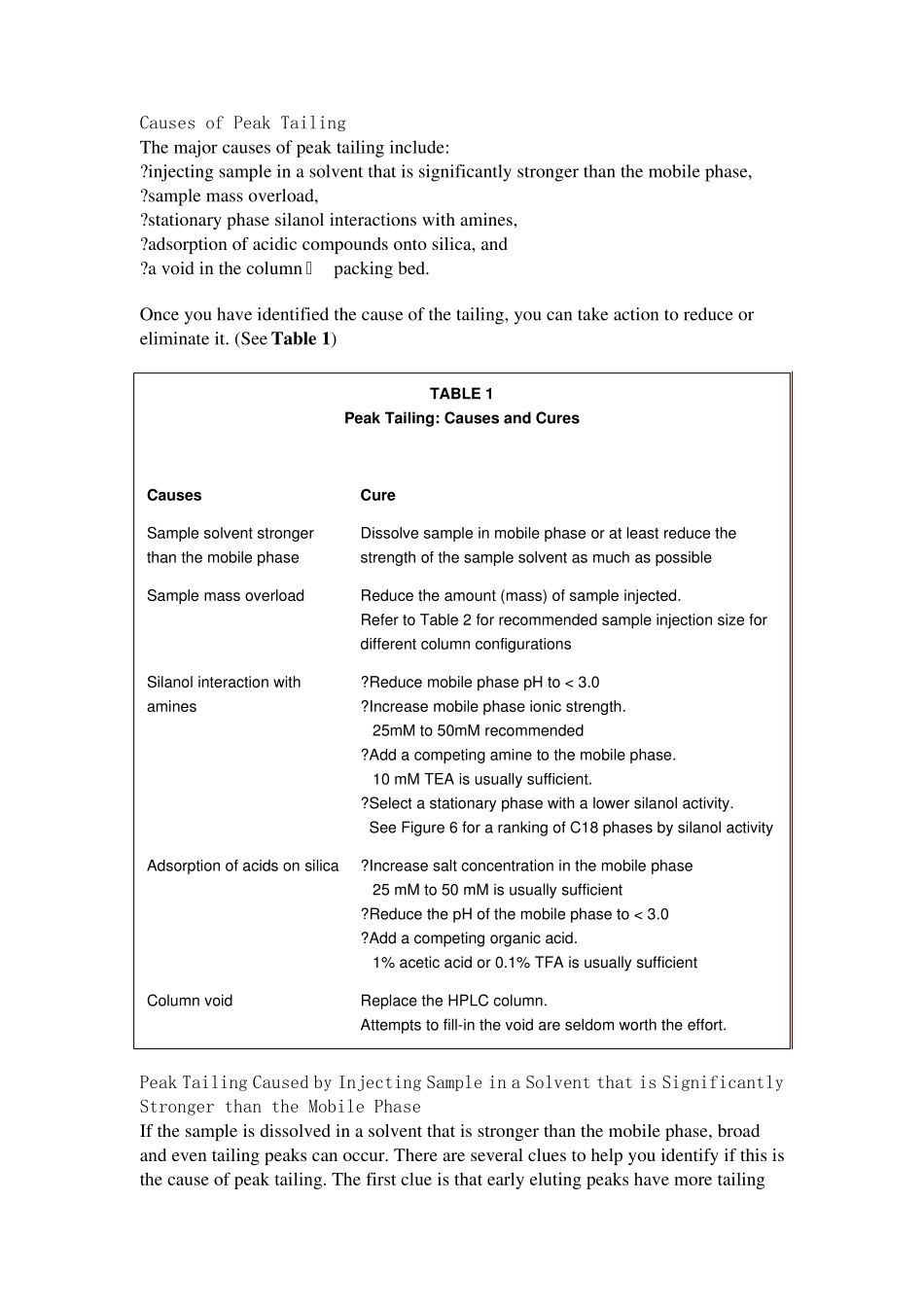

Correcting Peak Tailing Problems in Reversed Phase HPLC Peak tailing in reversed phase HPLC continues to be a common complaint. It is particularly prevalent when separating basic compounds and, therefore, a source of constant problems to those analyzing pharmaceutical compounds by HPLC. Peak tailing causes a number of problems, including lower resolution, reduced sensitivity, and poorer precision and quantitation. Figure 1 illustrates how resolution between peaks and sample sensitivity is negatively affected by peak tailing. Figure 2 illustrates how accuracy and precision of an analysis can suffer because of the inability of data systems to identify exactly where a tailing peak begins and ends. FIGURE 1 Effect of Peak Tailing on Resolution and Sensitivity As peak tailing (T, Tailing factor) increases from 1.0 to 2.0, resolution (R s ) decreases from 1.5 to 1.0. Sensitivity (peak height) also decreases with peak tailing since the peak volume increases and the sample concentration decreases. FIGURE 2 Accuracy and Precision is Adversely Affected by Peak Tailing Tailing peaks make it more difficult for data systems to identify exactly where a peak ends. Because of this, accuracy and precision can suffer. In this example, the peak area measured at point B is 3% less than the peak area measured at point A. Causes of Peak Tailing The major causes of peak tailing include: ?injecting sample in a solvent that is significantly stronger than the mobile phase, ?sample mass overload, ?stationary phase silanol interactions with amines, ?adsorption of acidic compounds onto silica, and ?a void in the column 抯 packing bed. Once you have identified the cause of the tailing, you can take action to reduce or elimina...