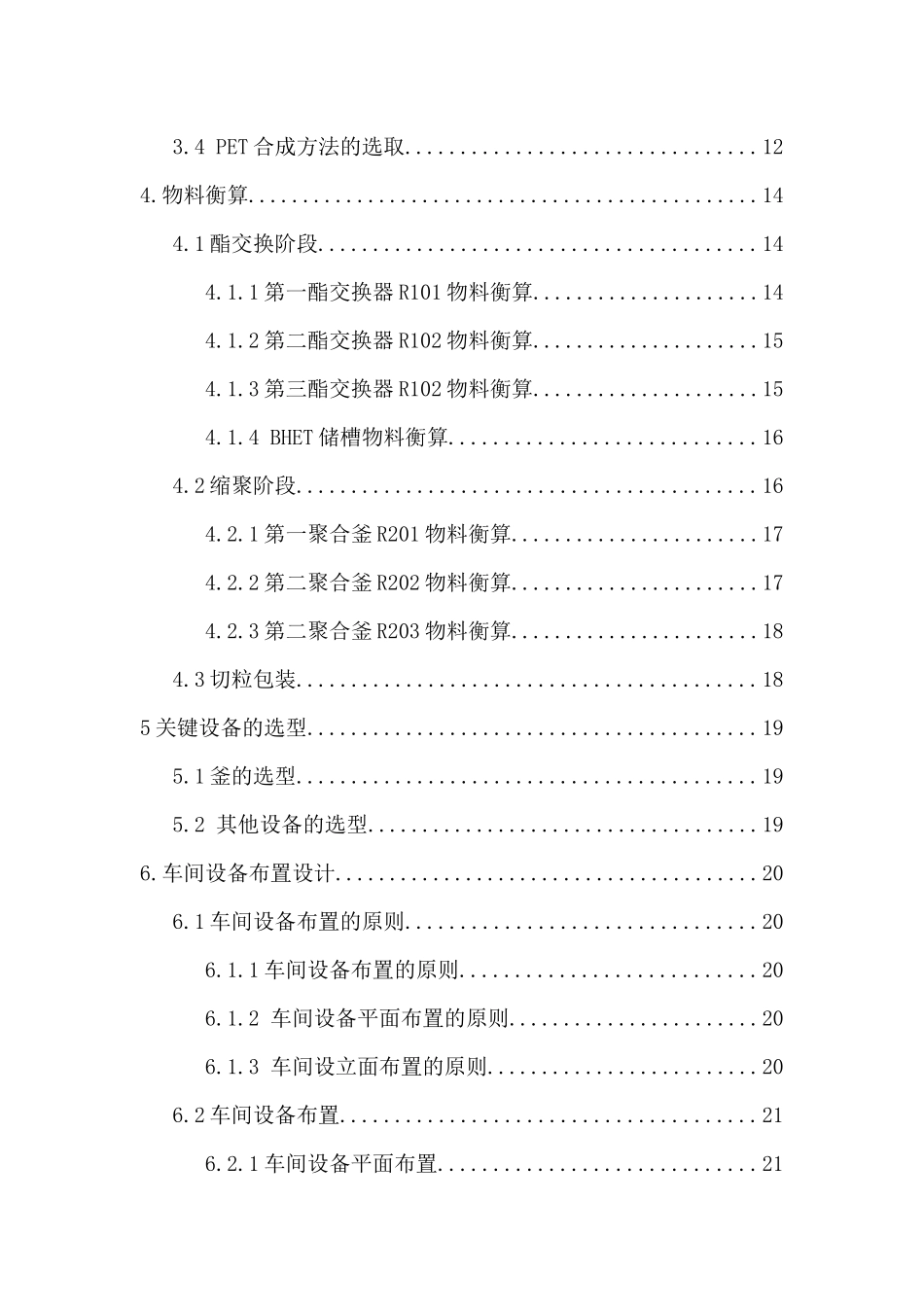

年产50万吨PET生产车间的工艺设计摘要本设计是年产50万吨聚对苯二甲酸乙二醇酯(PET)车间合成工段初步设计。本文对PET的研究,生产和应用进行了详细的概述,阐述了其在化学工业中的作用和地位。并介绍了PET的制备方法和确定了PET的生产工艺。在确定PET生产工艺的基础上进行了物料衡算,设备选型和车间设计等过程。文中还对供电、供水、采暖等方案进行了简单的阐述。关键词:聚对苯二甲酸乙二醇酯,PET,酯交换法,反应釜选型目录摘要......................................................I1.概述..................................................11.1聚对苯二甲酸乙二醇酯(PET)的概述...............11.2聚酯生产技术进展...................................11.3中国生产消费现状...................................21.4产品构成.........................................31.5中国聚酯工业及与国外先进水平的差距.................42.聚对苯二甲酸乙二醇酯(PET)的特性与应用.................62.1特性...............................................62.2应用...............................................82.3聚对苯二甲酸乙二醇酯的改性品种.....................82.3.1增强改性PET.................................82.3.2共混改性PET.................................92.3.3结晶改性PET.................................92.4聚对苯二甲酸乙二醇酯的成型加工.....................92.4.1PET的加工特性.................................92.4.2PET的加工方法...............................103.PET制备方法的简介和选取...............................113.1酯交换缩聚法......................................113.2直接酯化缩聚法....................................113.3环氧乙烷法........................................123.4PET合成方法的选取................................124.物料衡算...............................................144.1酯交换阶段........................................144.1.1第一酯交换器R101物料衡算.....................144.1.2第二酯交换器R102物料衡算.....................154.1.3第三酯交换器R102物料衡算.....................154.1.4BHET储槽物料衡算............................164.2缩聚阶段..........................................164.2.1第一聚合釜R201物料衡算.......................174.2.2第二聚合釜R202物料衡算.......................174.2.3第二聚合釜R203物料衡算.......................184.3切粒包装..........................................185关键设备的选型.........................................195.1釜的选型..........................................195.2其他设备的选型....................................196.车间设备布置设计.......................................206.1车间设备布置的原则................................206.1.1车间设备布置的原则...........................206.1.2车间设备平面布置的原则.......................206.1.3车间设立面布置的原则.........................206.2车间设备布置......................................216.2.1车间设备平面布置.............................216.2.2车间设备立面布置.............................217.公用工程..............................................227.1供水..............................................227.2供电..............................................227.3供暖..............................................227.4通风..............................................22参考文献.................................................23致谢.....................................................241.概述1.1聚对苯二甲酸乙二醇酯(PET)的概述聚对苯二甲酸乙二醇酯(PET)为聚对苯二甲酸和乙二醇直接酯化法或聚对苯二甲酸二甲酯与乙二醇酯交换法制成的聚...