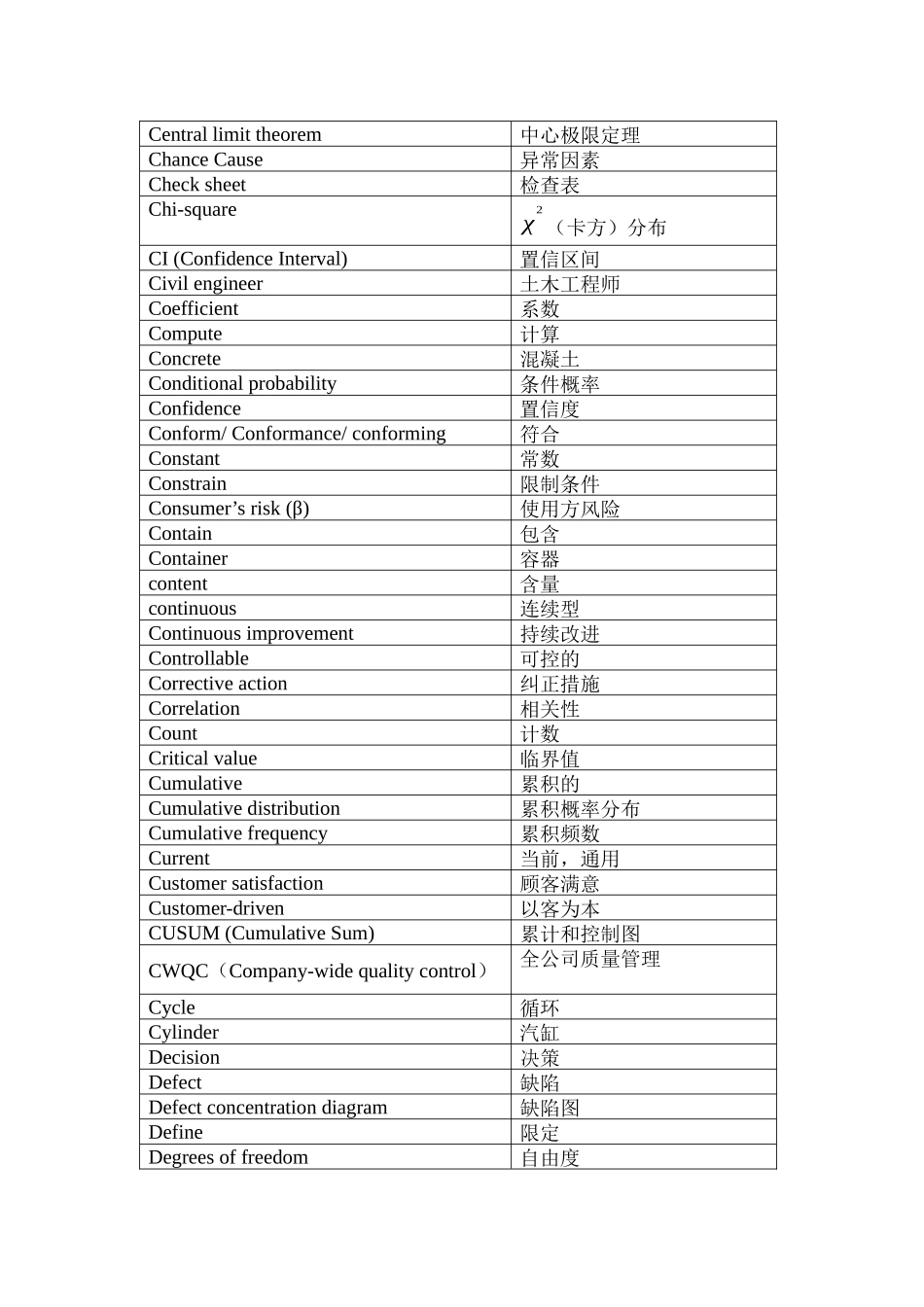

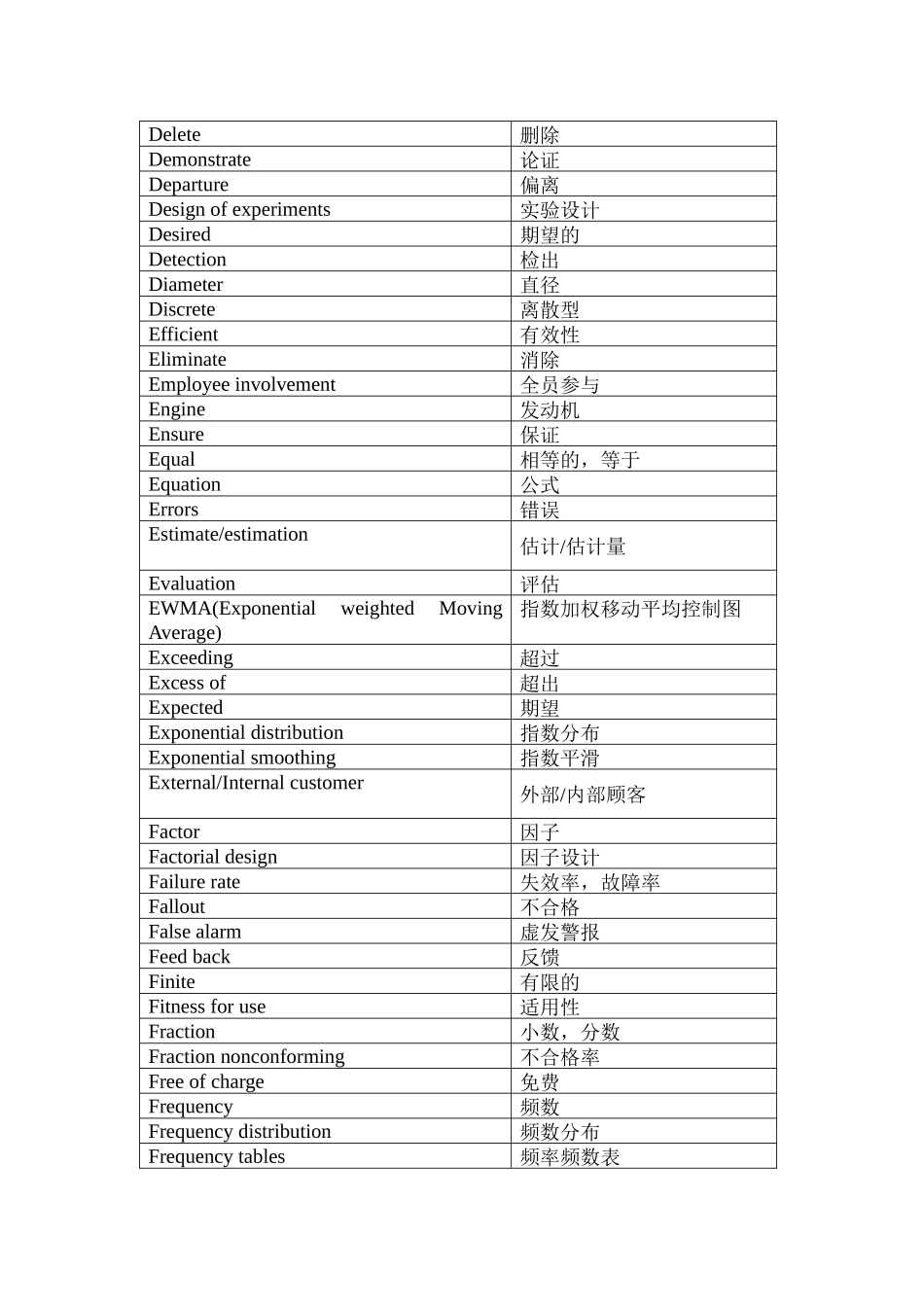

<统计学与质量管理>中英文对照表Accept接受Acceptancesampling验收抽样Accurate精确Actualdata实际值Adjust调整Adopt采用Aircraft飞机Allow允许Alternativehypothesis备择假设Approach趋近Approximately/approximation近似ARL(Averagerunlength)平均链长Assembly装配Assignablecause异常因素Assignedto分配...工作Assume/Assumption假设(动词)/假设(名词)ATS(Averagetimetosignal)平均报警时间Attentive加严Attributes计数数据Automotive汽车Average平均,均值Batch批量Bearing轴承Bell-shaped钟形Bernoullidistribution贝努利分布Beverage饮料Biased有偏的Bin柱Binomialdistribution二项分布Can罐头Capable过程能力强Casting铸造Cause–and-effectDiagram因果图Centerline中心线Centertendency中心倾向Centered/Centering(如分布中心与规范中心等)中心重合Centrallimittheorem中心极限定理ChanceCause异常因素Checksheet检查表Chi-squareχ2(卡方)分布CI(ConfidenceInterval)置信区间Civilengineer土木工程师Coefficient系数Compute计算Concrete混凝土Conditionalprobability条件概率Confidence置信度Conform/Conformance/conforming符合Constant常数Constrain限制条件Consumer’srisk(β)使用方风险Contain包含Container容器content含量continuous连续型Continuousimprovement持续改进Controllable可控的Correctiveaction纠正措施Correlation相关性Count计数Criticalvalue临界值Cumulative累积的Cumulativedistribution累积概率分布Cumulativefrequency累积频数Current当前,通用Customersatisfaction顾客满意Customer-driven以客为本CUSUM(CumulativeSum)累计和控制图CWQC(Company-widequalitycontrol)全公司质量管理Cycle循环Cylinder汽缸Decision决策Defect缺陷Defectconcentrationdiagram缺陷图Define限定Degreesoffreedom自由度Delete删除Demonstrate论证Departure偏离Designofexperiments实验设计Desired期望的Detection检出Diameter直径Discrete离散型Efficient有效性Eliminate消除Employeeinvolvement全员参与Engine发动机Ensure保证Equal相等的,等于Equation公式Errors错误Estimate/estimation估计/估计量Evaluation评估EWMA(ExponentialweightedMovingAverage)指数加权移动平均控制图Exceeding超过Excessof超出Expected期望Exponentialdistribution指数分布Exponentialsmoothing指数平滑External/Internalcustomer外部/内部顾客Factor因子Factorialdesign因子设计Failurerate失效率,故障率Fallout不合格Falsealarm虚发警报Feedback反馈Finite有限的Fitnessforuse适用性Fraction小数,分数Fractionnonconforming不合格率Freeofcharge免费Frequency频数Frequencydistribution频数分布Frequencytables频率频数表FTR(Failuretoreject)接受Gear齿轮Histogram直方图Historicaldata历史数据Homogenous同类的Hypergeometricdistribution超几何分布Hypothesistesting假设检验Identify识别Illustrate说明Implementation实施Incontrol控制状态In.英寸inadequate不足Incorrectdimension尺寸错误Independent相互独立Indicate表明Individual单值Individualmeasurement单值测量Inevitable不可避免的Inexperiencedoperator缺乏经验的工作人员Infinite无限的Infinity无穷Insidediameter内径Inspection检验Inspectionunit检查单位Installation安装Instantaneous短期的Instantaneousvariability短期变异Interpretation解释Interval(inhistogram)组距Intervalestimation区间估计Inverselyproportional成反比Investigation调查Irregular异常ISO(InternationalorganizationforStandards)国际标准化组织Isolate分离Iteration迭代Landing降落LCL(Lowercontrollimit下控制限Leak渗漏Leavealone不做调整Linearregression线性回归Locate位于Location位置Lot批LSL(lowerspecificationlimits)下规范限Magnificentseven质量控制七种工具Magnitude量值Maintain维修Manpower人力Massproduction大规模生产Material材料Max最大值Mean均值Meanshift均值偏移Measurement测量Memoryless无记忆性Methodo...