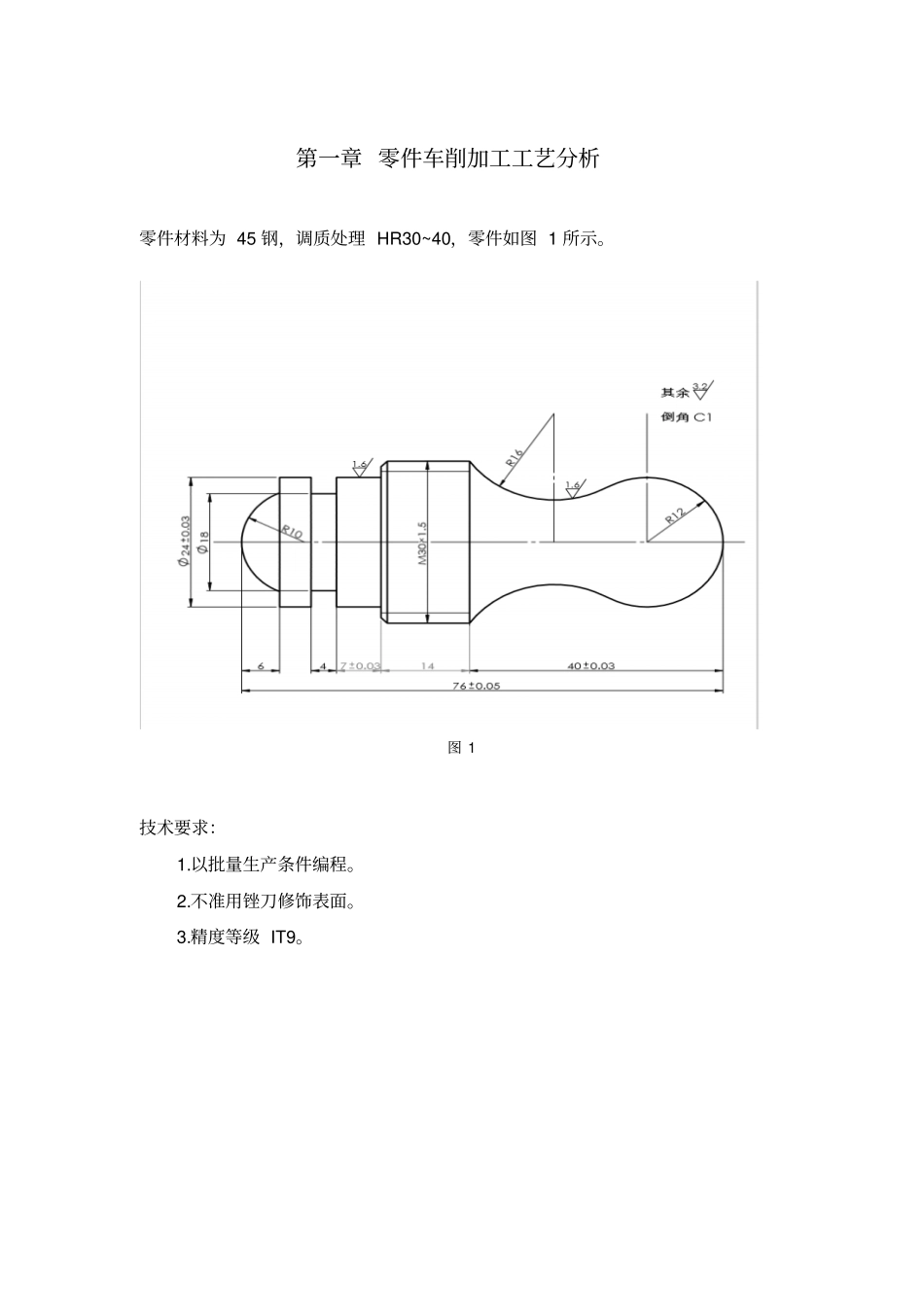

目录第一章零件车削加工工艺分析.....................................................................................................11.1设备选择.....................................................................................................................21.2确定零件的定位基准和装夹方式.............................................................................21.2.1粗基准选择原则................................................................................................21.2.2精基准选择原则................................................................................................21.2.3定位基准............................................................................................................21.2.4装夹方式............................................................................................................31.3确定工序.....................................................................................................................41.4选择刀具.....................................................................................................................51.5选择切削用量.............................................................................................................51.5.1选择主轴转速....................................................................................................51.5.2选择进给速度....................................................................................................51.5.3选择背吃刀量....................................................................................................6第二章程序编制及模拟运行.........................................................................................................72.1程序.............................................................................................................................72.2模拟运行.....................................................................................................................92.2.1选择操作系统和机床型号................................................................................92.2.2定义毛坯............................................................................................................92.2.3选择刀具..........................................................................................................102.2.4试切法对刀......................................................................................................122.2.5运行第一段程序..............................................................................................132.2.6第二次装夹......................................................................................................132.2.7第二次对刀......................................................................................................142.2.8运行第二段程序..............................................................................................14参考资料.......................................................................................................................................15第一章零件车削加工工艺分析零件材料为45钢,调质处理HR30~40,零件如图1所示。图1技术要求:1.以批量生产条件编程。2.不准用锉刀修饰表面。3.精度等级IT9。1.1设备选择根据该零件的外形是轴类零件,比较适合在车床上加工,由于零件上既有切槽尺寸精度又有圆弧数值精度,在普通车床上是难以保...