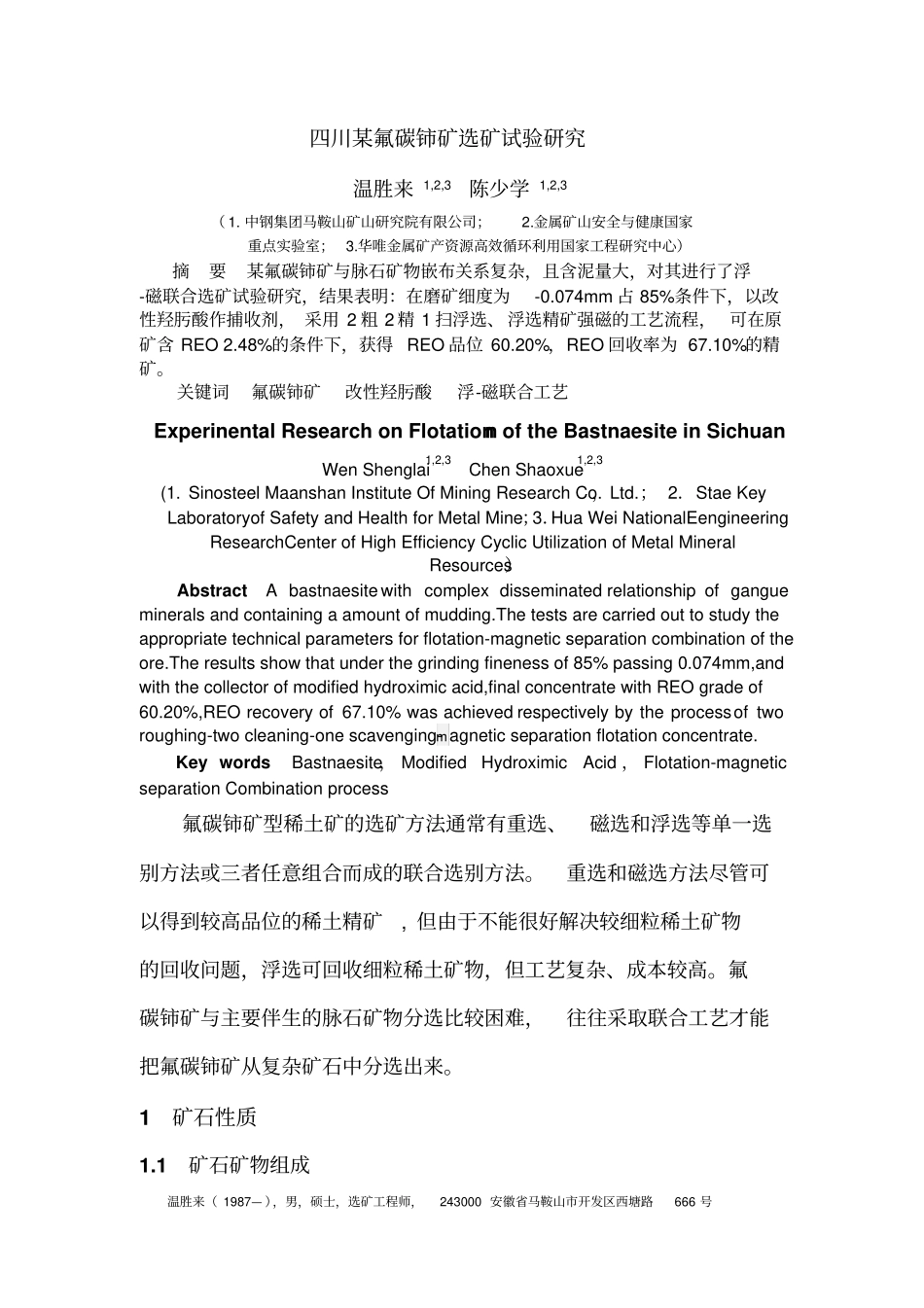

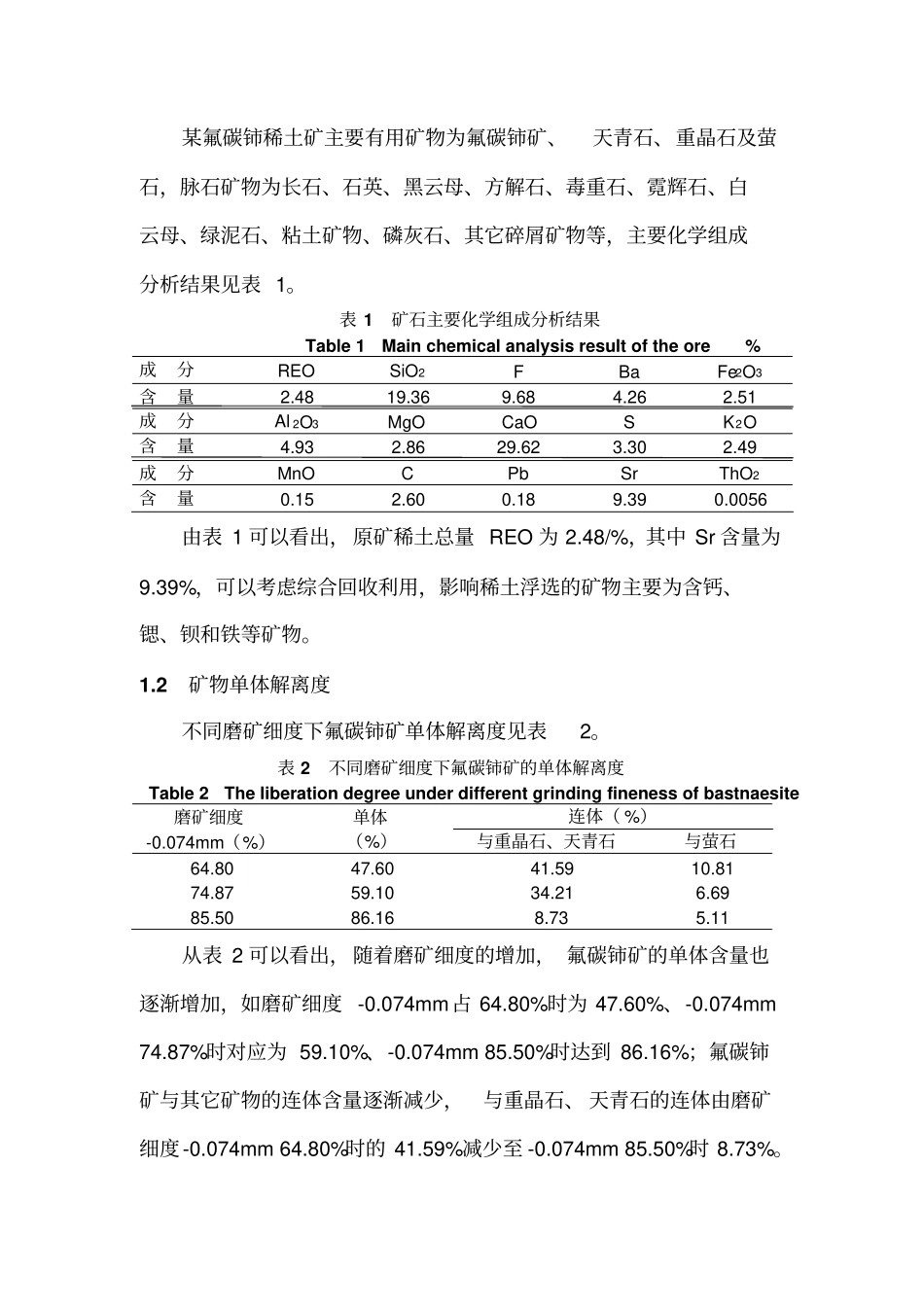

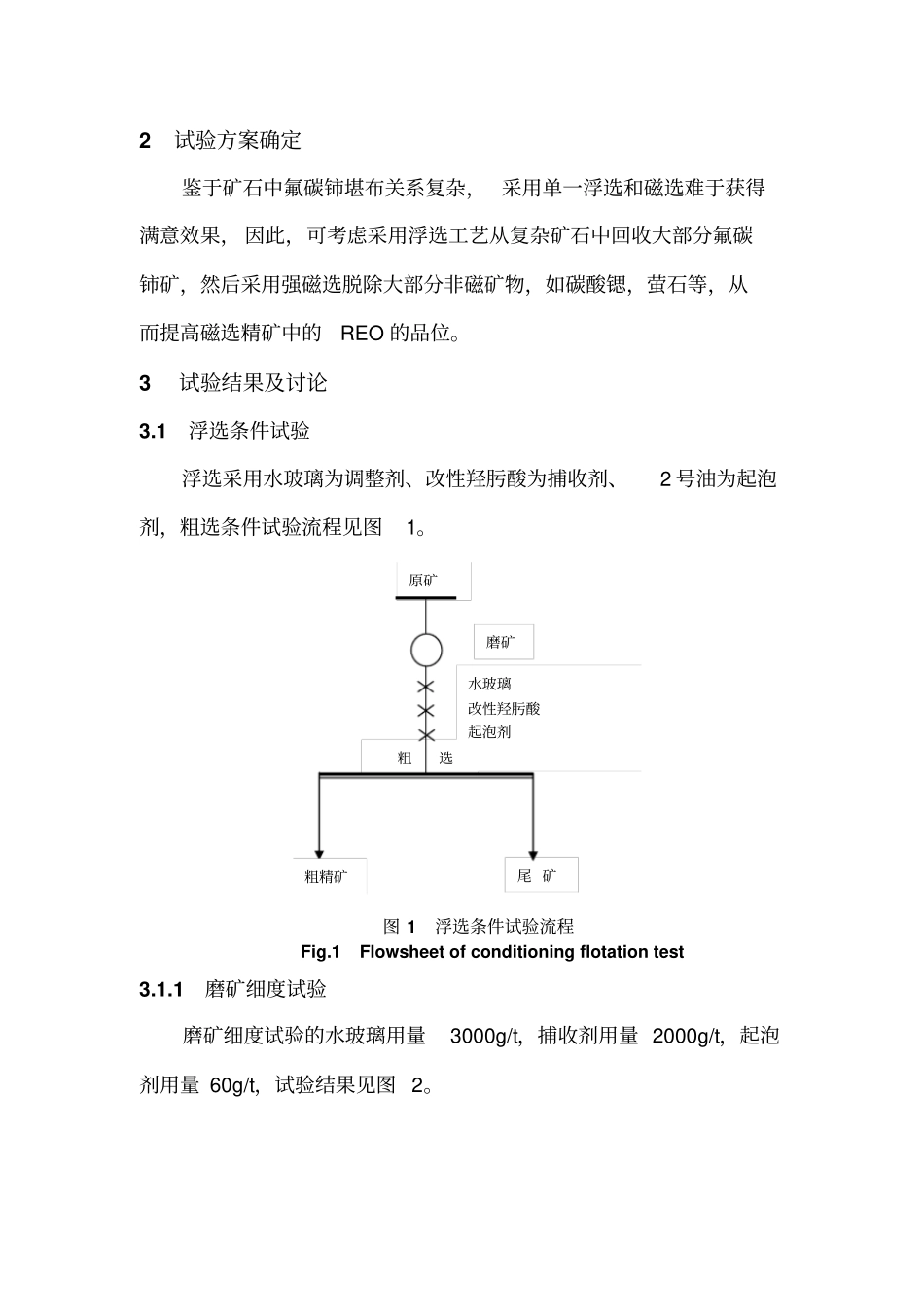

四川某氟碳铈矿选矿试验研究温胜来 1,2,3 陈少学 1,2,3 ( 1. 中钢集团马鞍山矿山研究院有限公司;2.金属矿山安全与健康国家重点实验室; 3.华唯金属矿产资源高效循环利用国家工程研究中心)摘要某氟碳铈矿与脉石矿物嵌布关系复杂,且含泥量大,对其进行了浮-磁联合选矿试验研究,结果表明:在磨矿细度为-0.074mm 占 85%条件下,以改性羟肟酸作捕收剂, 采用 2 粗 2 精 1 扫浮选、 浮选精矿强磁的工艺流程, 可在原矿含 REO 2.48%的条件下,获得 REO 品位 60.20%,REO 回收率为 67.10%的精矿。关键词氟碳铈矿改性羟肟酸浮-磁联合工艺Experinental Research on Flotationn of the Bastnaesite in Sichuan Wen Shenglai1,2,3 Chen Shaoxue1,2,3(1. Sinosteel Maanshan Institute Of Mining Research Co.,Ltd.; 2.Stae Key Laboratoryof Safety and Health for Metal Mine;3.Hua Wei NationalEengineering ResearchCenter of High Efficiency Cyclic Utilization of Metal Mineral Resources)Abstract A bastnaesite with complex disseminated relationship of gangue minerals and containing a amount of mudding.The tests are carried out to study the appropriate technical parameters for flotation-magnetic separation combination of the ore.The results show that under the grinding fineness of 85% passing 0.074mm,and with the collector of modified hydroximic acid,final concentrate with REO grade of 60.20%,REO recovery of 67.10% was achieved respectively by the process of two roughing-two cleaning-one scavenging-magnetic separation flotation concentrate. Key words Bastnaesite, Modified Hydroximic Acid , Flotation-magnetic separation Combination process 氟碳铈矿型稀土矿的选矿方法通常有重选、磁选和浮选等单一选别方法或三者任意组合而成的联合选别方法。重选和磁选方法尽管可以得到较高品位的稀土精矿, 但由于不能很好解决较细粒稀土矿物的回收问题,浮选可回收细粒稀土矿物,但工艺复杂、成本较高。氟碳铈矿与主要伴生的脉石矿物分选比较困难,往往采取联合工艺才能把氟碳铈矿从复杂矿石中分选出来。1矿石性质1.1 矿石矿物...