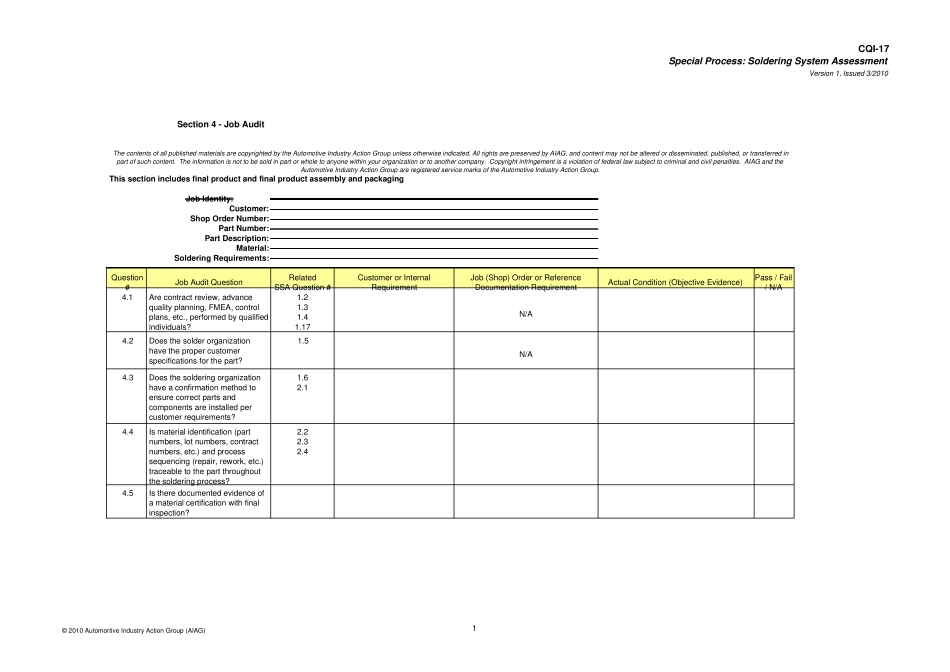

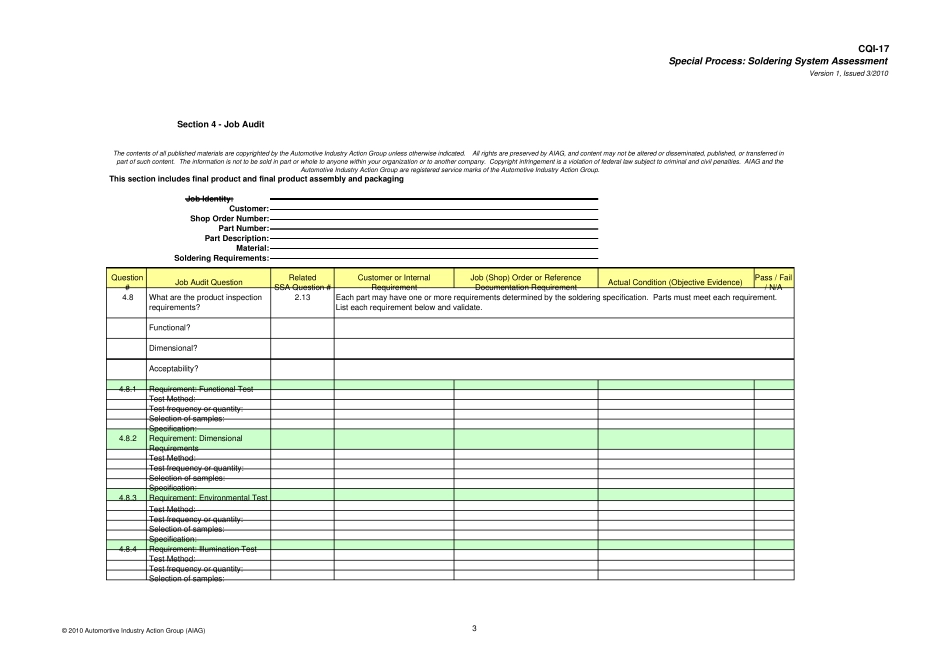

CQI-17Special Process: Soldering Sy stem AssessmentVersion 1, Issued 3/2010This section includes final product and final product assembly and packagingJob Identity:Customer:Shop Order Number:Part Number:Part Description:Material:Soldering Requirements:Question#Job Audit QuestionRelatedSSA Question #Customer or InternalRequirementJob (Shop) Order or ReferenceDocumentation RequirementActual Condition (Objective Evidence)Pass / Fail/ N/A4.1Are contract review, advancequality planning, FMEA, controlplans, etc., performed by qualifiedindividuals?1.21.31.41.17N/A4.2Does the solder organizationhave the proper customerspecifications for the part?1.5N/A4.3Does the soldering organizationhave a confirmation method toensure correct parts andcomponents are installed percustomer requirements?1.62.14.4Is material identification (partnumbers, lot numbers, contractnumbers, etc.) and processsequencing (repair, rework, etc.)traceable to the part throughoutthe soldering process?2.22.32.44.5Is there documented evidence ofa material certification with finalinspection?The contents of all published materials are copyrighted by the Automotive Industry Action Group unless otherwise indicated. All rights are preserved by AIAG, and content may not be altered or disseminated, published, or transferred inpart of such content. The information is not to be sold in part or whole to anyone within your organization or to another company. Copyright infringement is a violation of federal law subject to criminal and civil penalties. AIAG and theAutomotive Industry Action Group are registered service marks of the Automotive Industry Action Group.Section 4 - Job Audit© 2010 Automortive Industry Action Group (AIAG)1CQI-17Special Process: Soldering Sy stem AssessmentVersion 1, Issued 3/2010This sectio...