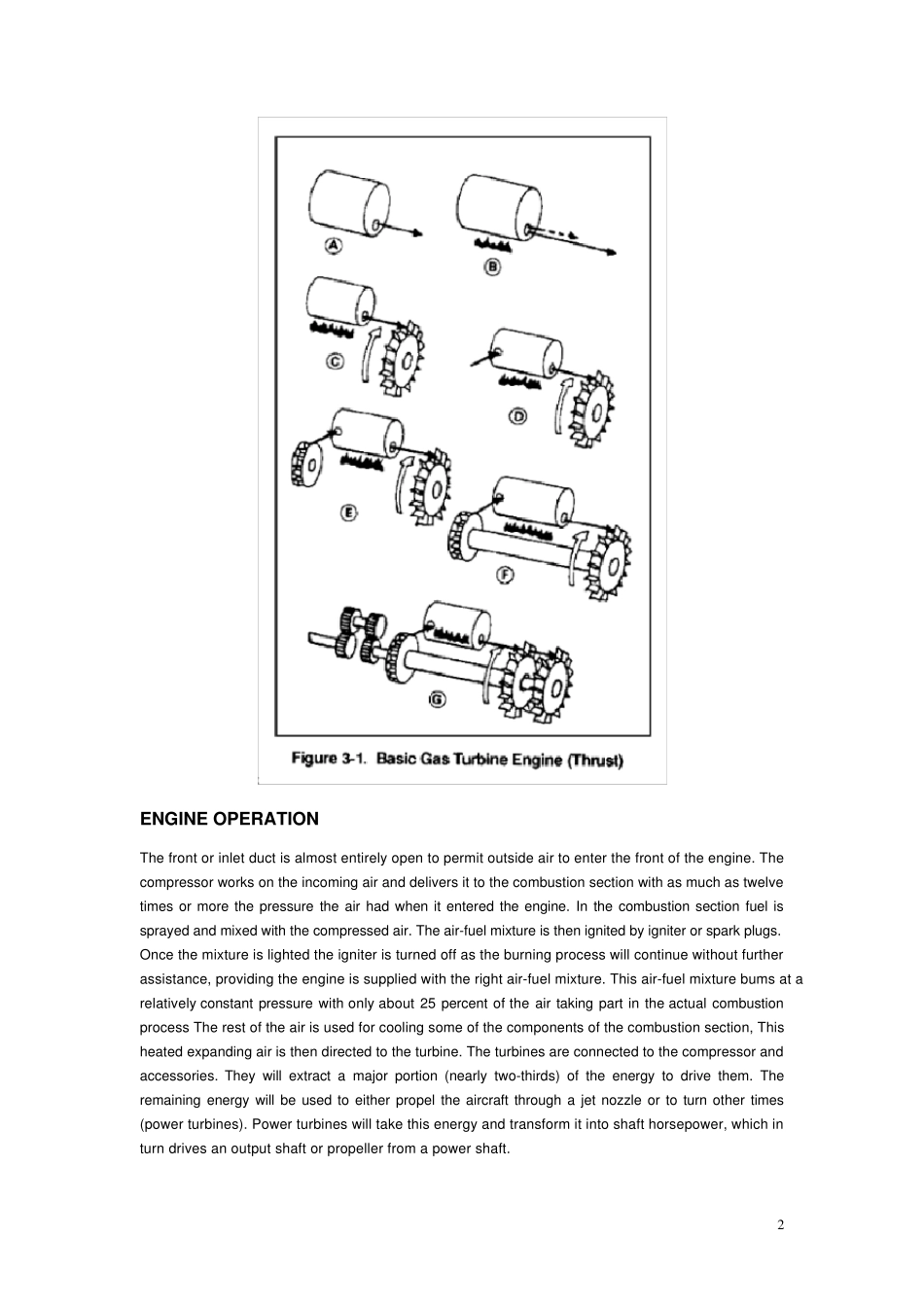

1 PART TW O. GAS TURBINE ENGINES CHAPTER 3 PRINCIPLES, OPERATION, AND CONSTRUCTION A gas turbine engine is an air-dependent, thermal jet propulsion device that uses exhaust-gas-driven turbine wheels to drive a compressor, making continuous operation of the engine possible. PRINCIPLES Although the gas turbine engine differs radically in construction from the conventional four-stroke, five-event cycle reciprocating engine, both operate on the same principle. In the piston (reciprocating) engine, the functions of intake, compression, combustion, and exhaust all take place in the same combustion chamber therefore, each must completely occupy the chamber during its respective part of the combustion cycle. In the gas turbine engine, a separate section is devoted to each function; all functions are performed at the same time without interruption. These sections are the air-inlet section the compressor section, the combustion section, and a turbine and exhaust section. The compressor brings in compresses, and forces air into the combustion section. Fuel is then injected into the combustion area, where it mixes with the compressed air. The fuel and air mixture is ignited by an electrical ignition plug; however, once started, ignition is shut off and combustion is continuous and self-supporting. In gas turbine engines designed for Army use, nearly two-thirds of the energy available from the products of combustion is necessary to drive the compressor. The power turbine is designed to extract as much of the remaining energy as possible from the gases and transform it into shaft horsepower which is used to drive an output shaft or propeller from a power shaft. A basic gas turbine engine is illustrated in Figure 3-1....