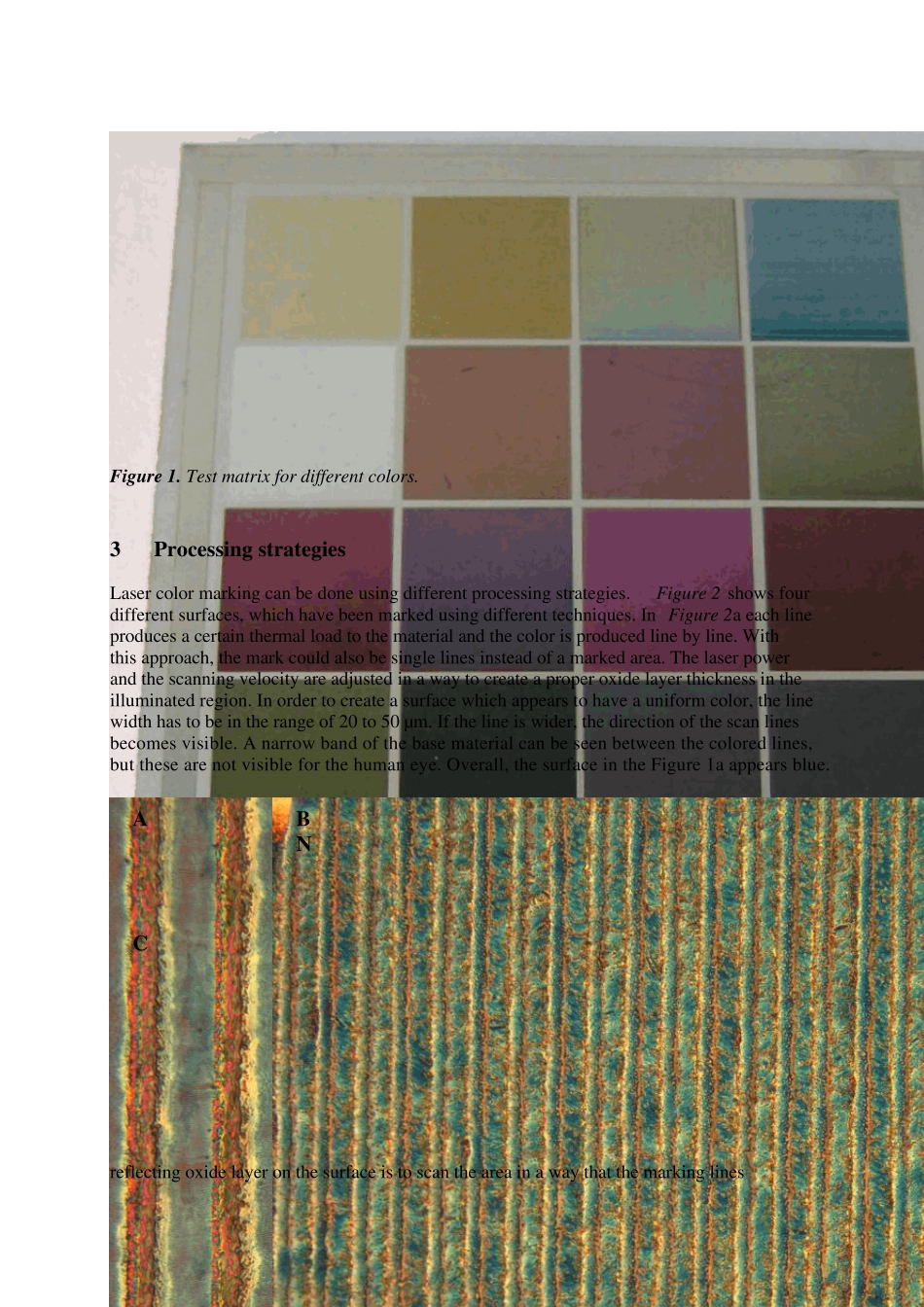

RELATION OF LASER PARAMETERS IN COLORMARKING OF STAINLESS STEELP. Laakso1, S. Ruotsalainen1, H. Pantsar2, R. Penttilä11 VTT, Lappeenranta, Finland2 Fraunhofer Center for Laser Technology, Plymouth, USAAbstractColor marking of stainless steels as a process is known for sometime but still it has not beenused widely in the industry. Some industrial applications have been seen. New MOPA fiberlasers allow independent tuning different laser parameters and the marking process can beoptimized for producing colors with better quality and visual appearance. Laser processing ofmetal surfaces creates an oxide layer on the surface. The thickness of this layer defines howwhite light is reflected from the sample. What in principle is only a thin oxide layer on thesurface can be seen as different colors by the viewer. In this study, the visual appearance oflaser marked surfaces was optimized by varying different laser parameters. The aim was tocreate a uniform oxide layers on the surface which would appear as a high quality colormarking. Marking quality was evaluated by visual examination. Relation of different laserparameters to produced color is discussed based on these results. Few application samples arealso presented.Keywords: laser marking, color, thin film effect1 IntroductionColor marking of metal surfaces is conventionally done by printing, anodization or emulsioncoating. However, the scratch properties of printing are limited and anodizing more than asingle color precisely is not easy. Emulsion coatings are more expensive and they require onestep more to produce colors. Lasers can be used to create a permanent color mark on a metalsurface as a one step process with a high throughput. Laser color marking of metals h...