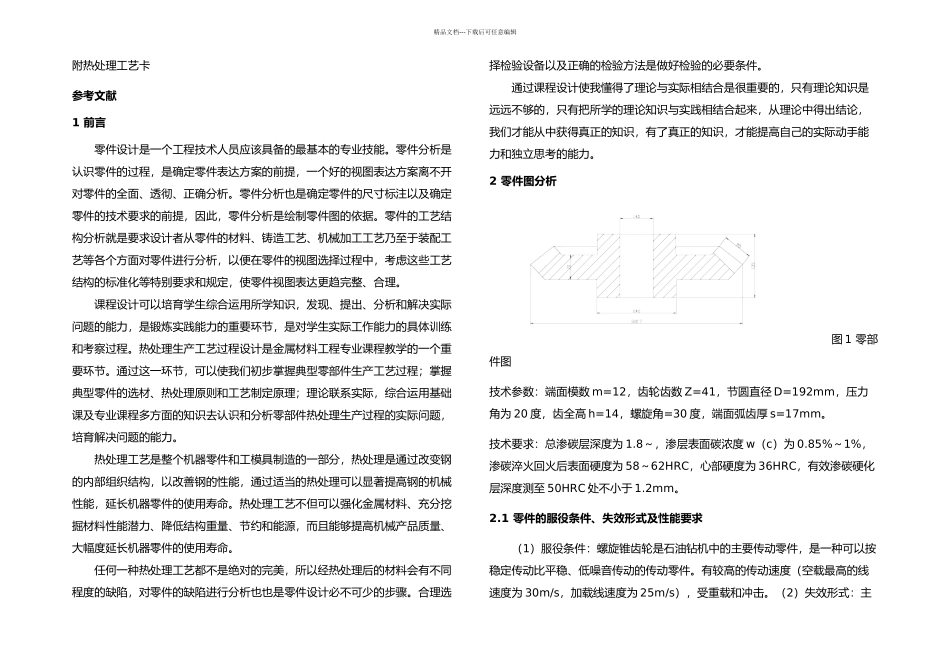

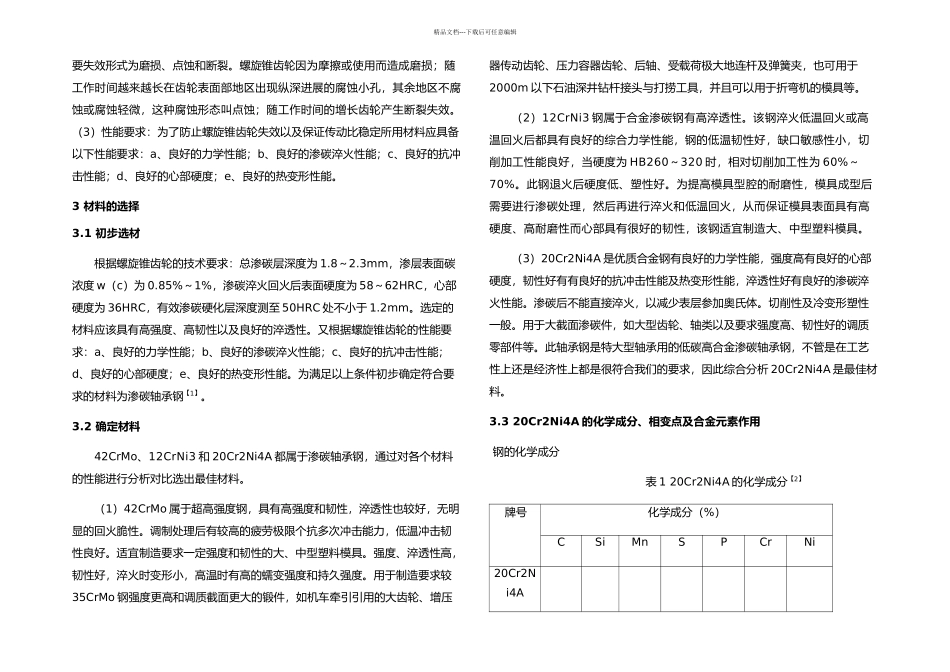

精品文档---下载后可任意编辑·················2··············3··············43.1 初步选材··············43.2 确定材料··············53.3 20Cr2Ni4A 的化学成分、相变点及合金元素作用·····64 确定加工路线4.1 初步确定加工路线············84.2 每个步骤的作用·············95 热处理工艺方法选择5.1 预备热处理工艺【4】的选择········105.2 渗碳工艺【5】的选择···········115.3 最终热处理【6】的选择··········126 制定热处理工艺的制度6.1 正火工艺的制定············126.2 高温回火工艺的制定6.3 渗碳工艺的制定··············176.4 高温回火工艺的制定·············216.5 淬火工艺的制定···············216.6 低温回火工艺的制定·············257 热处理设备选择 7.1 箱式电阻炉的选择··············27 7.2 井式渗碳炉的选择··············28 7.3 热处理冷却设备的选择············298 工装设计8.1 热处理夹具的选择··············30 8.2 热处理辅具·················319 检验设备及方法选择 9.1 外观····················35 9.2 硬度····················35 9.3 金相检查··················36 9.4 渗层深度··················3710 热处理缺陷分析10.1 正火缺陷分析················3810.2 回火缺陷分析················39 10.3 渗碳缺陷分析················3910.4 淬火缺陷分析················4111 小结精品文档---下载后可任意编辑附热处理工艺卡参考文献1 前言零件设计是一个工程技术人员应该具备的最基本的专业技能。零件分析是认识零件的过程,是确定零件表达方案的前提,一个好的视图表达方案离不开对零件的全面、透彻、正确分析。零件分析也是确定零件的尺寸标注以及确定零件的技术要求的前提,因此,零件分析是绘制零件图的依据。零件的工艺结构分析就是要求设计者从零件的材料、铸造工艺、机械加工工艺乃至于装配工艺等各个方面对零...