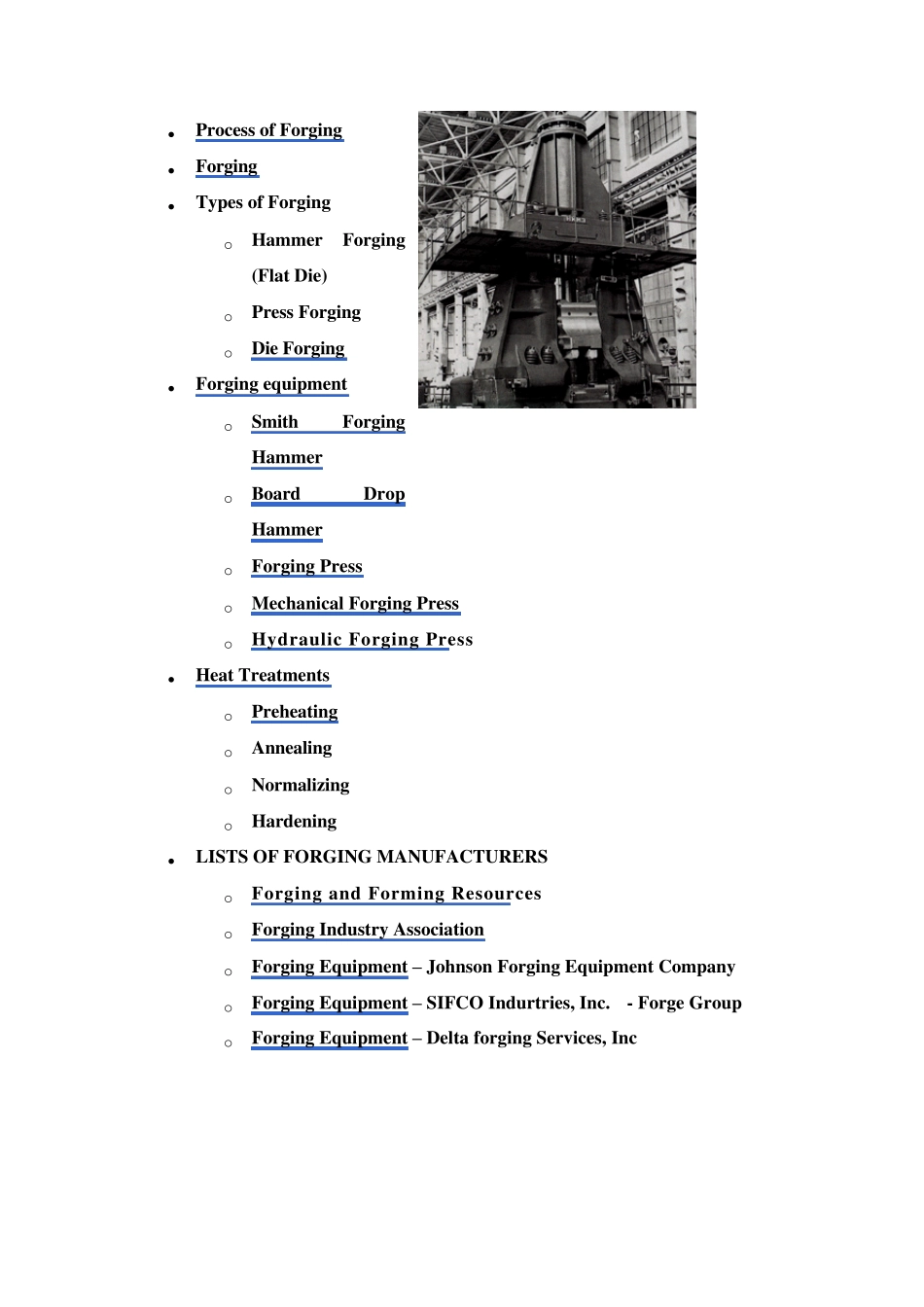

Process of Forging Forging Types of Forging o Hammer Forging (Flat Die) o Press Forging o Die Forging Forging equipment o Smith Forging Hammer o Board Drop Hammer o Forging Press o Mechanical Forging Press o Hydraulic Forging Press Heat Treatments o Preheating o Annealing o Normalizing o Hardening LISTS OF FORGING MANUFACTURERS o Forging and Forming Resources o Forging Industry Association o Forging Equipment – Johnson Forging Equipment Company o Forging Equipment – SIFCO Indurtries, Inc. - Forge Group o Forging Equipment – Delta forging Services, Inc Process: Forging is a metal forming process used to produce large quantities of identical parts, as in the manufacture of automobiles, and to improve the mechanical properties of the metal being forged, as in aerospace parts or military equipment. The design of forged parts is limited when undercuts or cored sections are required. All cavities must be comparatively straight and largest at the mouth, so that the forging die may be withdrawn. The products of forging may be tiny or massive and can be made of steel (automobile axles), brass (water valves), tungsten (rocket nozzles), aluminum (aircraft structural members), or any other metal. More than two thirds of forging in the United States is concentrated in four general areas: 30 percent in the aerospace industry, 20 percent in automotive and truck manufacture, 10 percent in off-highway vehicles, and 10 percent in military equipment. This process is also used for coining, but with slow continuous pushes. The forging metal forming process has been practiced since the Bronze Age. Hammering metal by hand can be dated back over 4000 years ago. The purpose, as it still is tod...