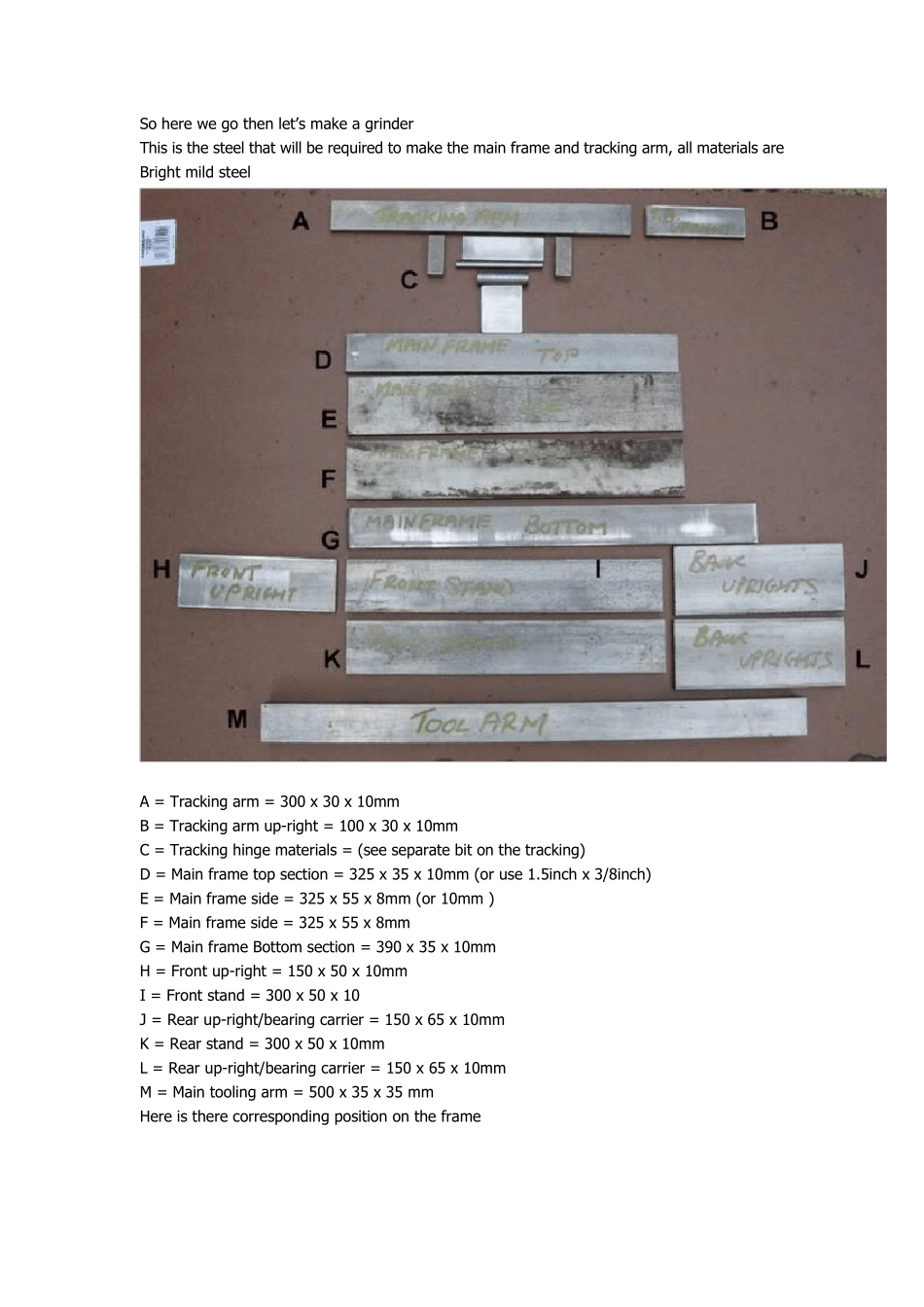

OK folks, there hasn’t been a grinder tutorial for sometime now, whenever I post one of mine up they get a lot of interest so thought I would show you how to make one of these It’s basically a KMG clone uses 1600 to 2000 x 50 belts and the great thing about these machines is there adaptability. It’s very simple to have a platen grinding head, contact wheel or small wheel attachment A general overview of the construction is, all welded main frame, sliding type tool arm lockable with a single fastener, single knob tracking system with variable spring tension, main drive pulley is 100mm Dia x 55mm wide Tracking pulley is 80 mm Dia ‘crowned’ x 55mm wide platen rollers 45mm Dia x 50mm wide. This will be run with a 2hp motor and three speed drive. For those of you that have seen one of these in action you’ll know just how good they really are!! As for the plan, their isn’t one, I’ve made quite a few of these now and the major problem that I have is obtaining a regular supply of steel the sizes that I want, so I make them with the steel that’s available to me, The good news is that all the dimensions given are quite adaptable; as long as you stick to very similar sizes you sho uldn’t go wrong. I will start of by making the main frame (the blue bit) first, It’s an all welded construction making for a very rigid frame, the disadvantage is you will need to be very careful in getting it clamped up square and spot on before you weld, as I’m sure you will appreciate it’s a real pain having to grind off welds when you get them wrong! I intend to complete the grinder right through to fitting the motor and running it. So here we go then let’s make a gr...