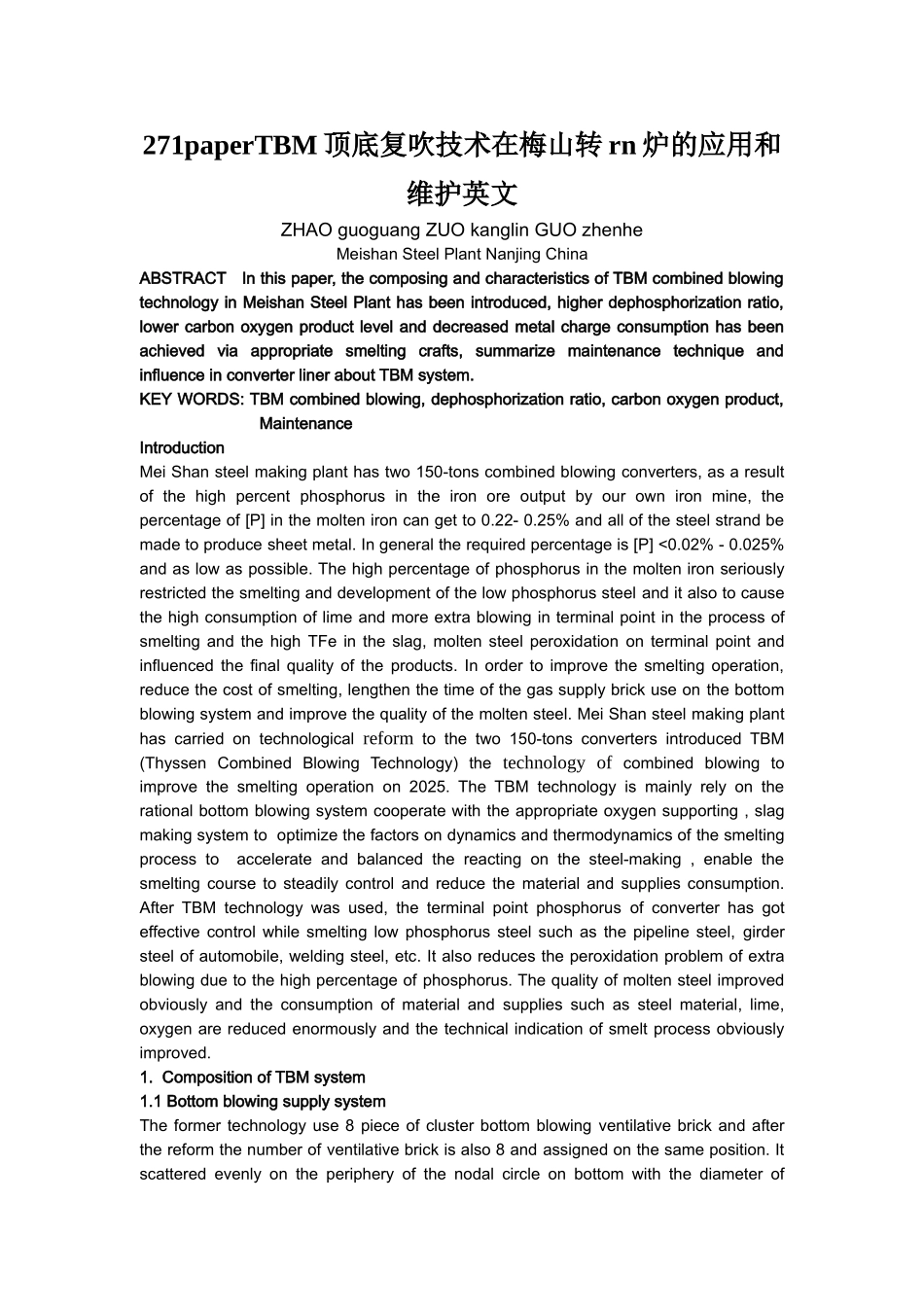

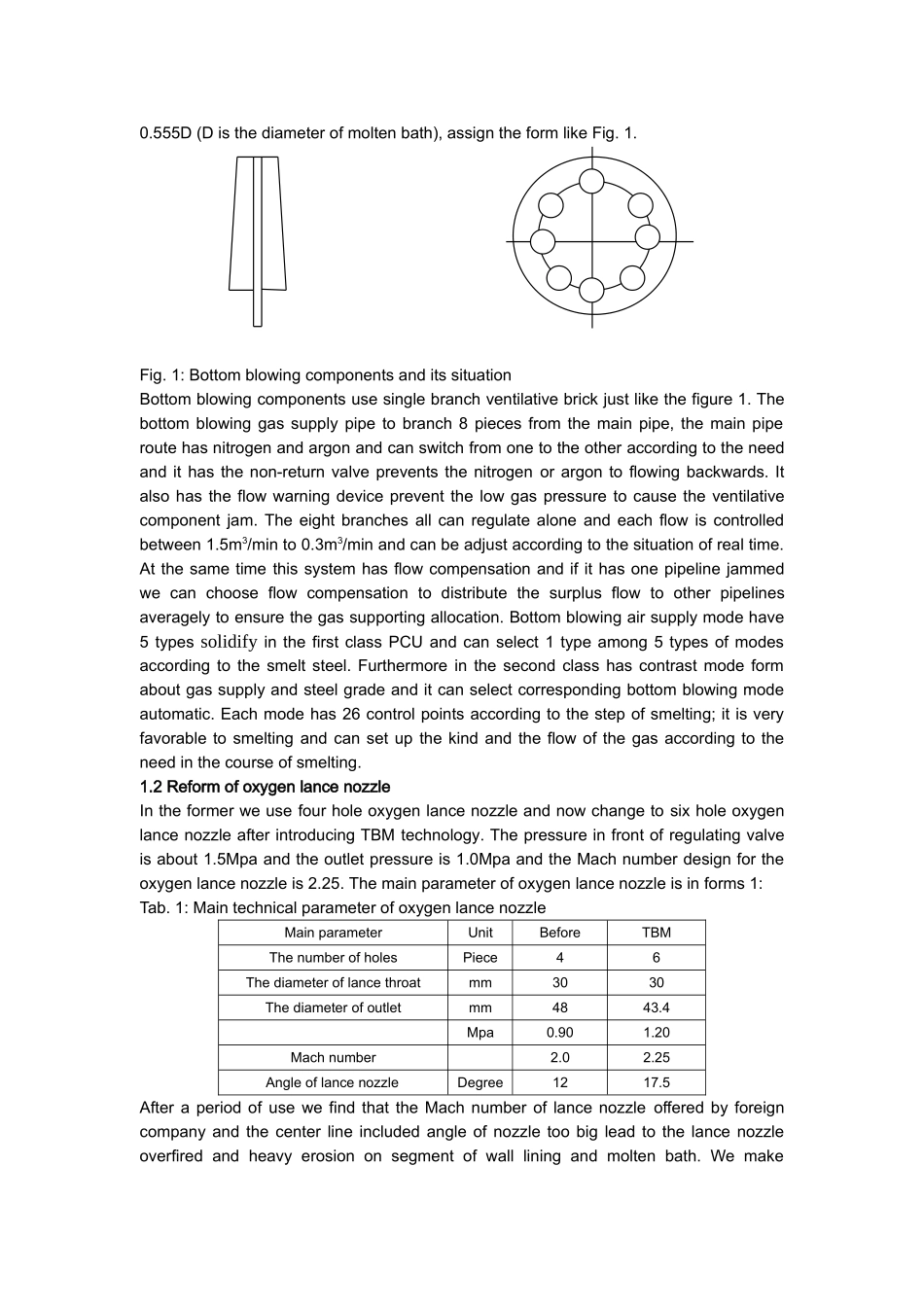

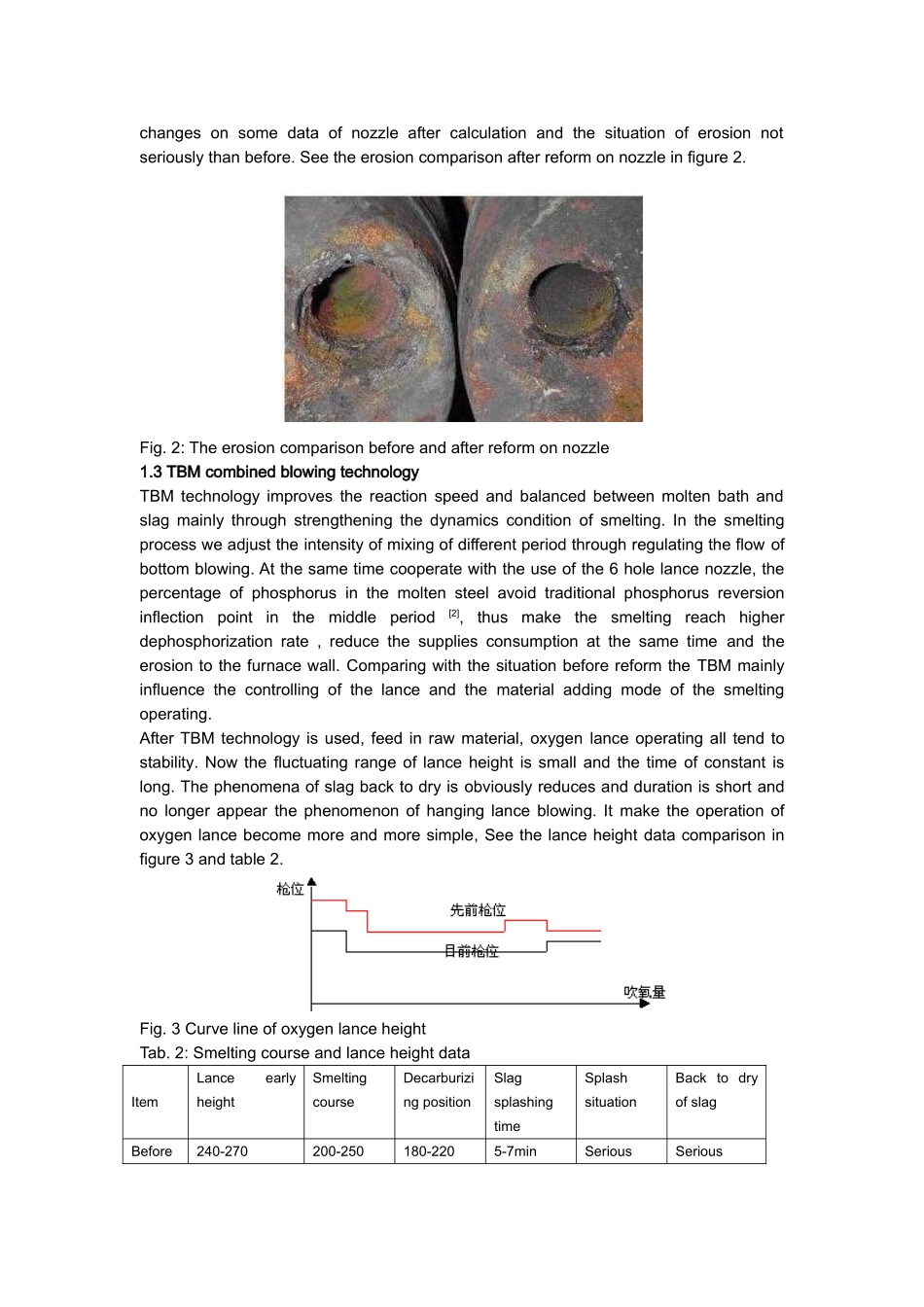

271paperTBM 顶底复吹技术在梅山转 rn 炉的应用和维护英文ZHAO guoguang ZUO kanglin GUO zhenhe Meishan Steel Plant Nanjing ChinaABSTRACT In this paper, the composing and characteristics of TBM combined blowing technology in Meishan Steel Plant has been introduced, higher dephosphorization ratio, lower carbon oxygen product level and decreased metal charge consumption has been achieved via appropriate smelting crafts, summarize maintenance technique and influence in converter liner about TBM system. KEY WORDS: TBM combined blowing, dephosphorization ratio, carbon oxygen product, Maintenance Introduction Mei Shan steel making plant has two 150-tons combined blowing converters, as a result of the high percent phosphorus in the iron ore output by our own iron mine, the percentage of [P] in the molten iron can get to 0.22- 0.25% and all of the steel strand be made to produce sheet metal. In general the required percentage is [P] <0.02% - 0.025% and as low as possible. The high percentage of phosphorus in the molten iron seriously restricted the smelting and development of the low phosphorus steel and it also to cause the high consumption of lime and more extra blowing in terminal point in the process of smelting and the high TFe in the slag, molten steel peroxidation on terminal point and influenced the final quality of the products. In order to improve the smelting operation, reduce the cost of smelting, lengthen the time of the gas supply brick use on the bottom blowing system and improve the quality of the molten steel. Mei Shan steel making plant has carried on technological reform to the two 150-tons converters introduced TBM (Thyssen Combined Blowing Technology) the technology of combined blowing to im...