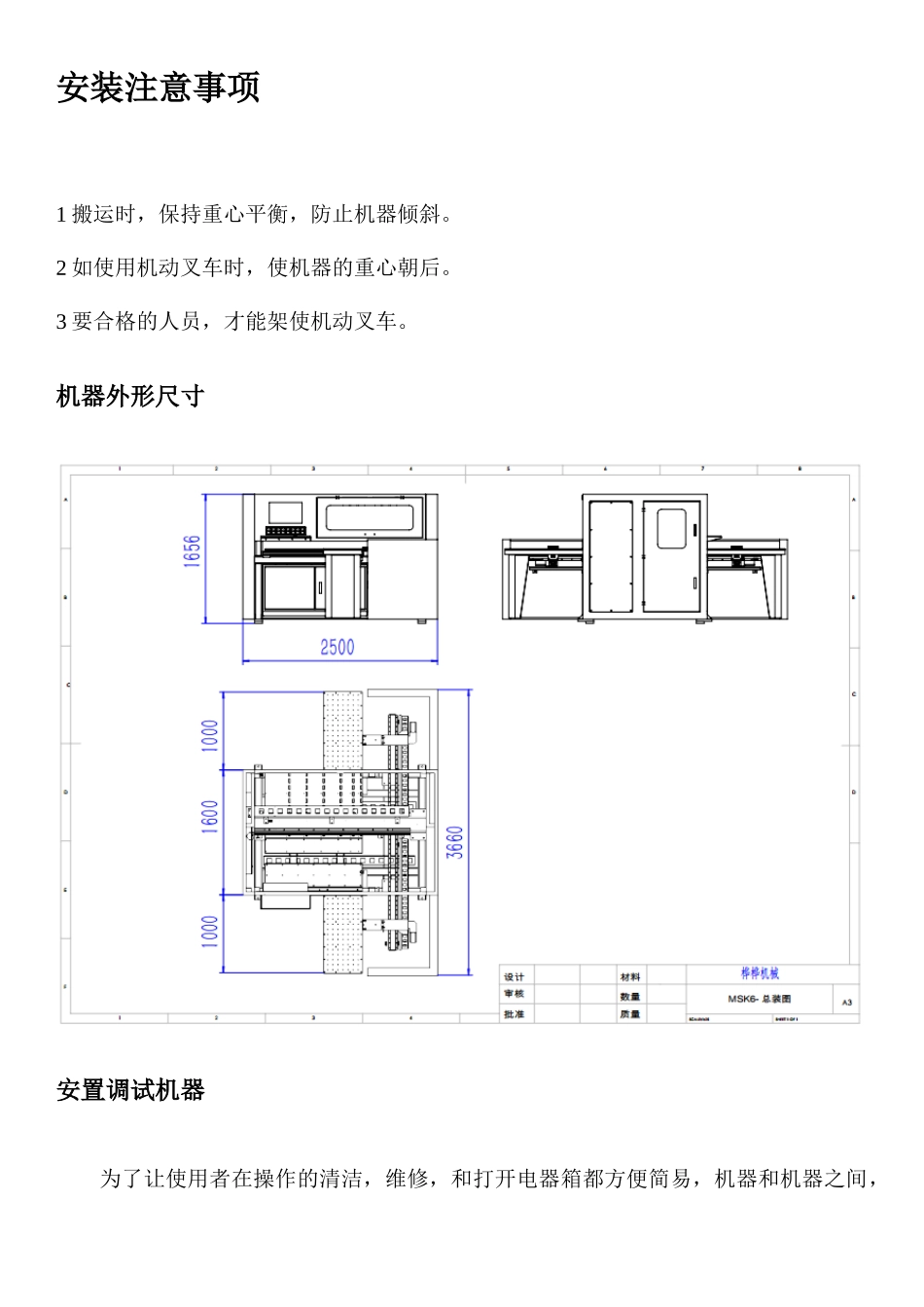

使用手册全自动六面钻铣加工中心SKS-690目录1、安装注意事项··································3-42、面板按钮开关··································53、安全注意事项··································64、作业指导·····································75、操作指导·····································86、M代码·······································97、组合键······································108、代码操作说明··································109、代码操作说明··································1010、常见故障处理··································11-1611、连续扫描加工使用方法···························16-1812、ROM软件更新································18-2313、VGA切换·····································2414、机台坐标系····································2515、电路图········································26-3516、配件清单······································3617、产品保修卡····································3718、合格证·······································38页···············································39未经培训使用的人员禁止操作此设备操作主机手须详细的阅读此说明书安装注意事项1搬运时,保持重心平衡,防止机器倾斜。2如使用机动叉车时,使机器的重心朝后。3要合格的人员,才能架使机动叉车。机器外形尺寸安置调试机器为了让使用者在操作的清洁,维修,和打开电器箱都方便简易,机器和机器之间,或是和墙壁,和其他物件要放在一起时,机器每一边至少都要保持1000mm以上的距离。本机不能直接安置在地板上,须使用调整螺丝与垫片调整水平高度。使用场地的地板需是平坦的水泥地面,勿放在不稳定的根基上,不然终将造成机械的不平衡。水平校正使用以下工具调整机器水平:1.4支六角头螺丝M16*60L。2.垫子。3.水平仪请用精度0.02/M以上,调整精度请保持在±0.04以内。4.工具箱扳手。先清理台面,放置水平仪在横和纵两方向,转动调整到水平仪指示的水平处。电源连接1.所有线路连接工作,需由合格的人员执行。2.确定供电电压和机器电压符合。3.主要动力线,是要接入电器箱里,R.S.T的端子上。4.使用1条电线,单根线径至少要4mm²。5.设备一定要接地,绝不能和其他机械共同接地接通,因为如有其他机械露电,将会倒冲至电脑主机而造成无法维修之损坏。注意:接地线务必遵照规定!(深度大于1.5米以上)首次安装设备使用前检查1.设备所有电路快速接口、航空接头、VGA、数据线等接口2.气压和气缸进给速度检查(压板、压轮、机械手、Z轴辅助气缸)3.压板、压轮、机械手信号灯检查4.X轴、Y轴、Z轴、U轴、V轴、W轴、A轴、水平刀具*4、定位柱、机械手光电接近开关锁紧度检查5.设备在使用前请配套吸尘机操作台按钮开关功能图标名称功能说明急停EMERGENCY当发现机器运转不正常或发生紧急情况时,可按下此按钮,全部动作停止,并报“紧急停止”故障,再次启动设备必须释放此按钮,也就是只需顺时针方向旋转大约45°后松开钥匙开关LOCK1此开关为控制电源启动和停止的开关2此开关选择到”ON”处,电源控制回路及伺服主回路都会接通电源,处于待机状态。3此开关选择到”O...