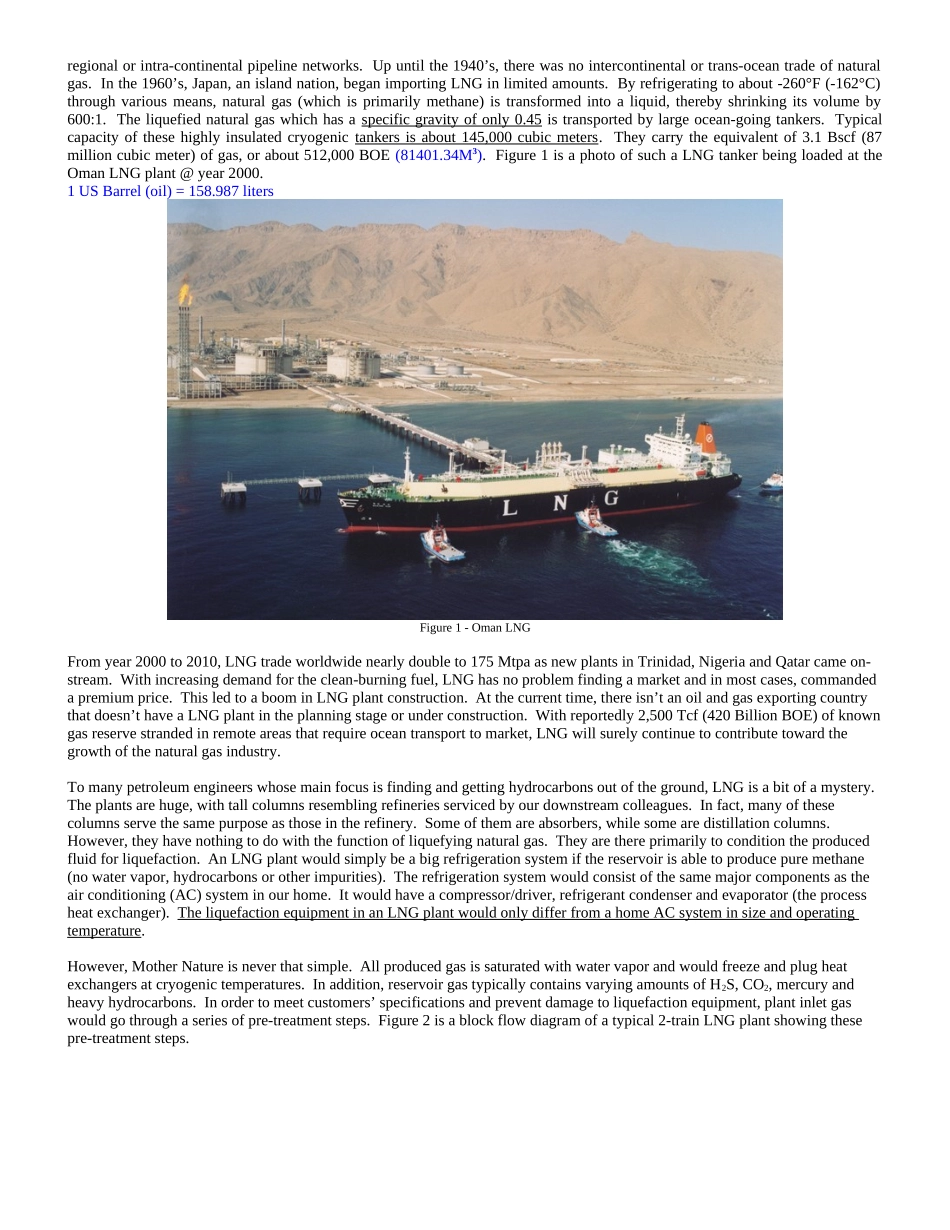

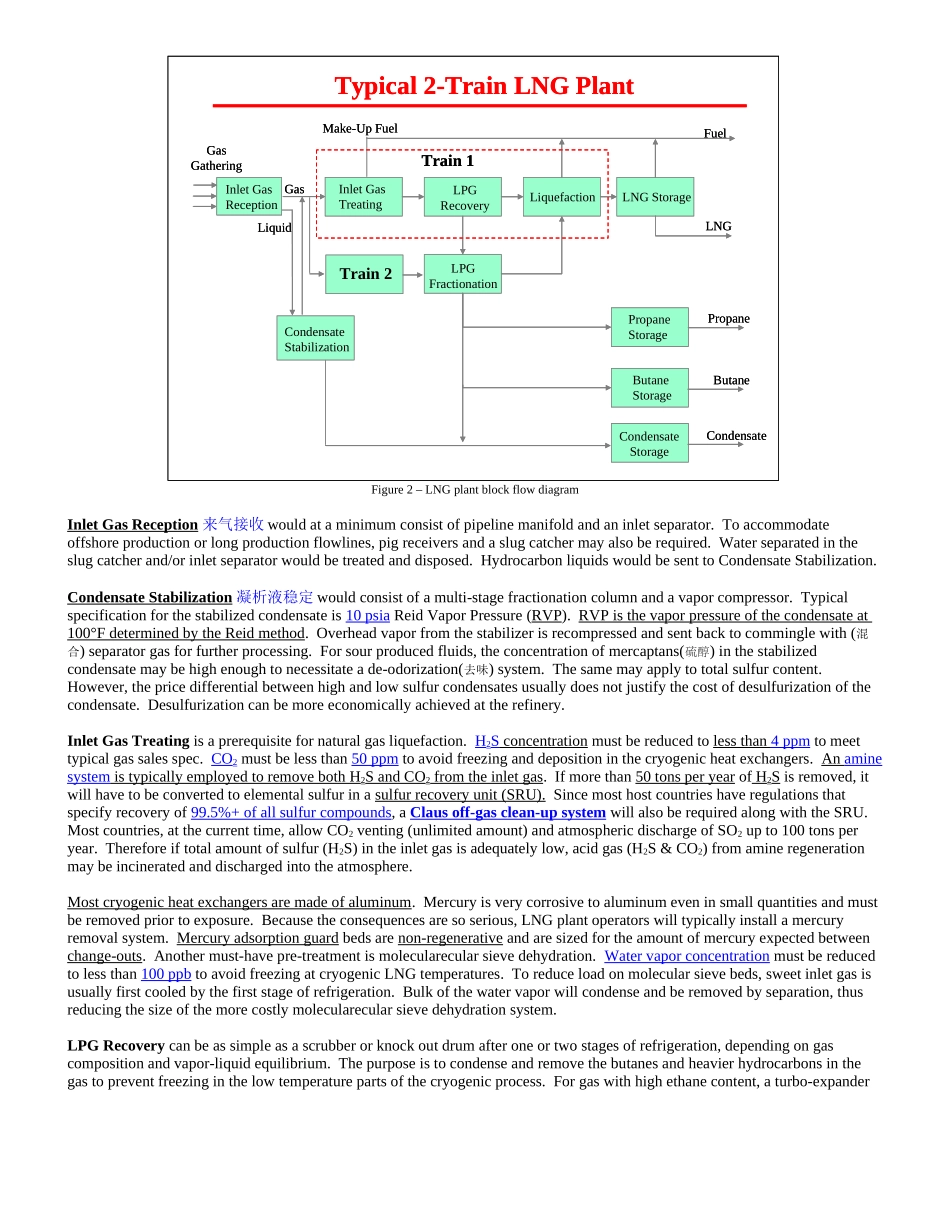

Copyright2010,SocietyofPetroleumEngineersThispaperwaspreparedforpresentationattheSPEAnnualTechnicalConferenceandExhibitionheldinFlorence,Italy,19–22September2010.ThispaperwasselectedforpresentationbyanSPEprogramcommitteefollowingreviewofinformationcontainedinanabstractsubmittedbytheauthor(s).ContentsofthepaperhavenotbeenreviewedbytheSocietyofPetroleumEngineersandaresubjecttocorrectionbytheauthor(s).ThematerialdoesnotnecessarilyreflectanypositionoftheSocietyofPetroleumEngineers,itsofficers,ormembers.Electronicreproduction,distribution,orstorageofanypartofthispaperwithoutthewrittenconsentoftheSocietyofPetroleumEngineersisprohibited.Permissiontoreproduceinprintisrestrictedtoanabstractofnotmorethan300words;illustrationsmaynotbecopied.TheabstractmustcontainconspicuousacknowledgmentofSPEcopyright.AbstractWhileremotepartsoftheworldareawashwithhundredsoftrillionsofcubicfeet(Tcf)ofnaturalgas,theindustrializedWestandemergingeconomiesoftheEastcan’tgetenoughoftheclean-burning,environmentallyfriendlyfuel.Theproblemistransportingthiscompressiblefluidlongdistances,acrossmajorbodiesofwater.Formarketsgreaterthan1,500miles,liquefiednaturalgas(LNG)hasprovedtobethemosteconomicoption.Byrefrigeratingnaturalgas(primarilymethane)to-260ºF(-162ºC),therebyshrinkingitsvolumeby600:1,LNGcanbetransportedinlargeinsulatedcryogenictankersatreasonablecost.Naturalgasliquefactionisaseriesofrefrigerationsystemssimilartotheairconditioningsysteminourhomesconsistingofacompressor,condenserandevaporatortochillandcondensethegas.Thedifferenceisinthescaleandmagnitudeoftherefrigeration.Atypicalsingle-trainLNGplantmaycost$1.5billionandconsume6-8%oftheinletgasasfuel.Sincemanyoftheimpurities(watervapor,carbondioxide,hydrogensulfide,etc.)andheavierhydrocarboncompoundsinnaturalgaswillfreezeatLNGtemperatures,theymustfirstberemoved,anddisposedormarketedasseparateproducts.ThispaperwillprovideanoverviewofLNGliquefactionfacilities,frominletgasreceivingtoLNGstorageandloading.However,thefocusisontheliquefactionprocessandequipment.Differencesamongthecommerciallyavailableliquefactionprocesses(cascade,singlemixedrefrigerant,propane-pre-cooledmixedrefrigerant,doublemixedrefrigerant,nitrogen,etc.)willbediscussed.TheaimistoprovideSPEmemberswithaclearunderstandingofthetechnologies,equipmentandprocesschoicesrequiredforasuccessfulLNGproject.IntroductionTheliquefiednaturalgas(LNG)industryiscurrentlyexperiencingexplosivegrowth.Thereisn’tanoilandgasexportingcountrythatdoesn’thaveaLNGplantintheplanningstageorunderconstruction.TheArabStateofQataralonewillbebringingon50millionmetrictonsperyear(Mtpa)ofproductioninthenext3years.Thisisequivalenttoabout6.6Bscfdofpipelinegas.Inaddition,newprojectsintheAtlanticBasin,AsiaPacificandMiddleEastcouldwelldoublethatfigureinthesametimeframe.Theexcitementisdrivenbytheconvergence(集合)oftechnologyandmarket.Therearereportedly2,500Tcf(420BillionBOE)ofknownnaturalgasreservestranded(搁浅)inremoteareas.Thebarriertotapingthisabundantsourceofcleanenergyhasbeenthecostofliquefactionandshipping.Withrecentadvancesinliquefactiontechnologiesandrisingnaturalgasprice,thetimehasfinallyarrivedforLNGtobeeconomicallyattractivetobothproducerandconsumer.AirProducts&ChemicalsInc.’s(APCI)Propane-precooledMixedRefrigerantprocesshasdominatedbaseloadLNGtechnologywithabout75%oftheexistingplantcapacity.However,revitalization(新...