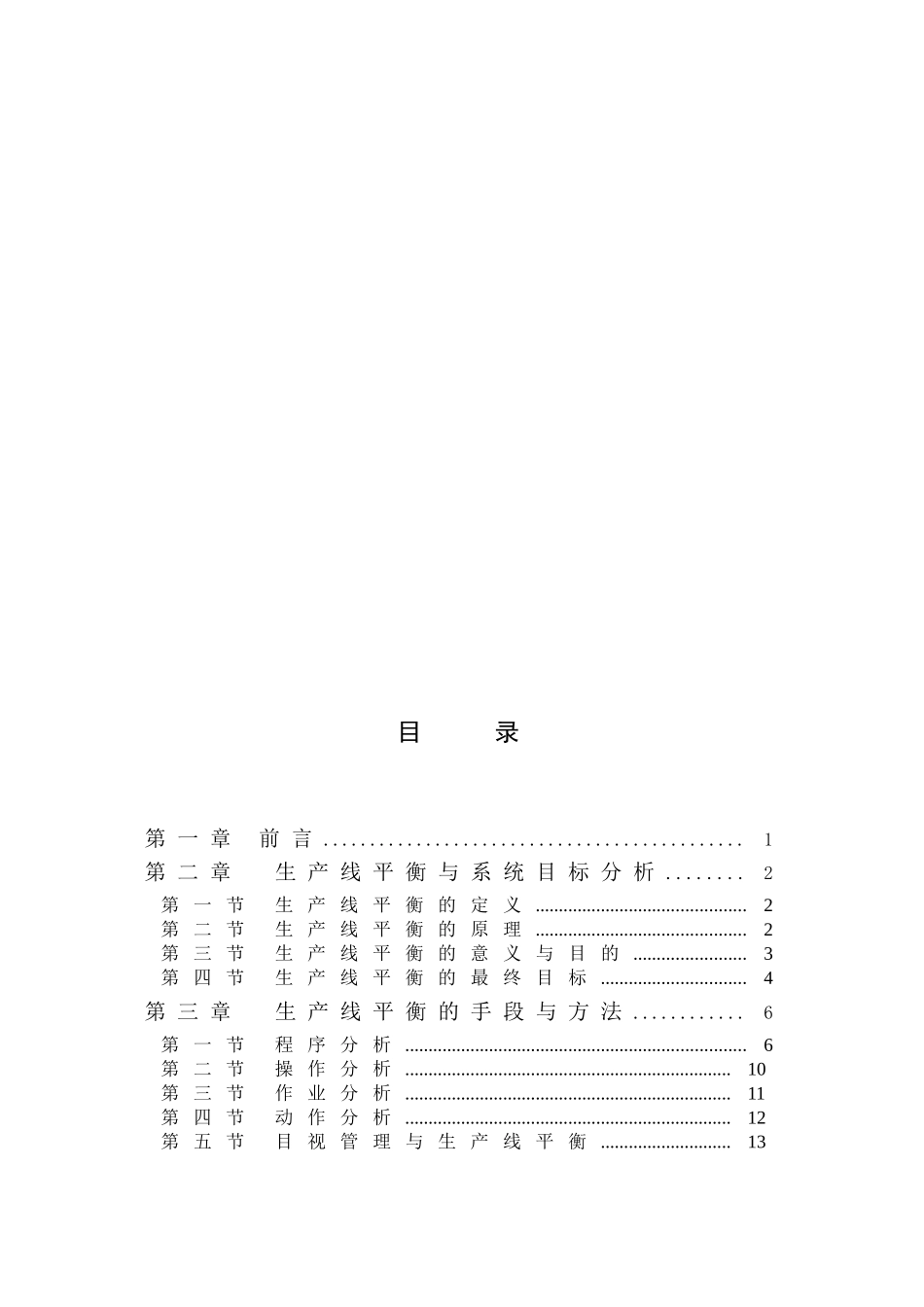

内容摘要本文基于电子制造企业对生产线平衡性所追求的重要指标,企业生产中通常用生产线平衡率这一量化指标来评价一条流水线的平衡性高低,它在某种程度上决定着企业设备的利用率并且限制着生产线的生产能力提高。本文系统地介绍了平衡性对企业流水线的重要作用和平衡率的原理和计算;利用自己在宁波奇美电子企业实习的机会收集了大量的相关数据和文件资料,来论述基础工业工程在企业中平衡流水线的重要作用,并以针对企业内存在的一些问题说明怎样用程序分析来解决工序流程不合理,用操作分析来解决人机之间的合理结合问题,用动作研究来寻找“经济动作”和阐述双手作业的效益,用模特法确定标准作业时间以及通过提高关键工序的生产能力,来达到生产线平衡的目标。而且论文还简明扼要地介绍了“目视管理”技术对流水线均衡的重要性,以使业内人士从不同角度对现今仍然广泛盛行的流水线平衡作进一步的思考和优化。关键词:生产线平衡、工作研究、程序分析、目视管理ABSTRACTTheproductionlinebalancedstateisatargetwhichtheproductionconfigurationenterprisepursues,Theenterpriseproducesusuallyappraisesanassemblylinewiththeequilibriumratiosthisquantificationtargetthebalancedheight,Anditdecidestheenterpriseequipmentusefactortolimittheproductionlineproductivityenhancementtoacertainextent.Thisarticlesystematicallybriefedthebalancedstatetotheenterpriseassemblylinevitalroleandtheequilibriumratiosprincipleandthecomputation;HascollectedthemassivecorrelationdatasandthedocumentmaterialusingoneselfinratherthePouchbeautifulelectronenterprisepracticeopportunity,Elaboratesthefoundationindustrialengineeringtobalancetheassemblylineintheenterprisethevitalrole,Andaimsatsomequestionswhichintheenterpriseexiststoexplainhowusestheprocedureanalysistosolvetheworkingprocedureflownottobeunreasonable,Solvesbetweentheman-machinereasonableunionproblemwiththeoperationalanalysis,Seeks“theeconomicalmovement”withthemovementresearchandtheelaborationbothhandsworkbenefit,Withthemodellawdeterminedthestandardworktimeaswellasthroughenhancestheessentialworkingprocedureproductivity,Achievestheproductionlinebalancethegoal.Moreoverthepaperalsobrieflyandtothepointintroduced“thevisualmanagement”thetechnicalconvectionwaterlinebalancedimportance.Causedtheprofessionaltheassemblylinewhichwasstillwidespreadtothenowadaysisinvoguetomakethefurtherponderandtheoptimizationfromthedifferentangle.KEYWORDS::ProductionLineBalancingSimulationoptimizationprocedureanalysisVisualizationSimulation目录第一章前言.............................................1第二章生产线平衡与系统目标分析........2第一节生产线平衡的定义.............................................2第二节生产线平衡的原理.............................................2第三节生产线平衡的意义与目的........................3第四节生产线平衡的最终目标...............................4第三章生产线平衡的手段与方法............6第一节程序分析.........................................................................6第二节操作分析......................................................................10第三节作业分析......................................................................11第四节动作分析......................................................................12第五节目视管理与生产线平衡............................13第四章生产线的现状问题分析及改善...15第一节生产线的现状及问题分析.....................15第二节企业生产线平衡优化改善对策.......19第三节改善后的效果确认..........................................20第五章结论........................................