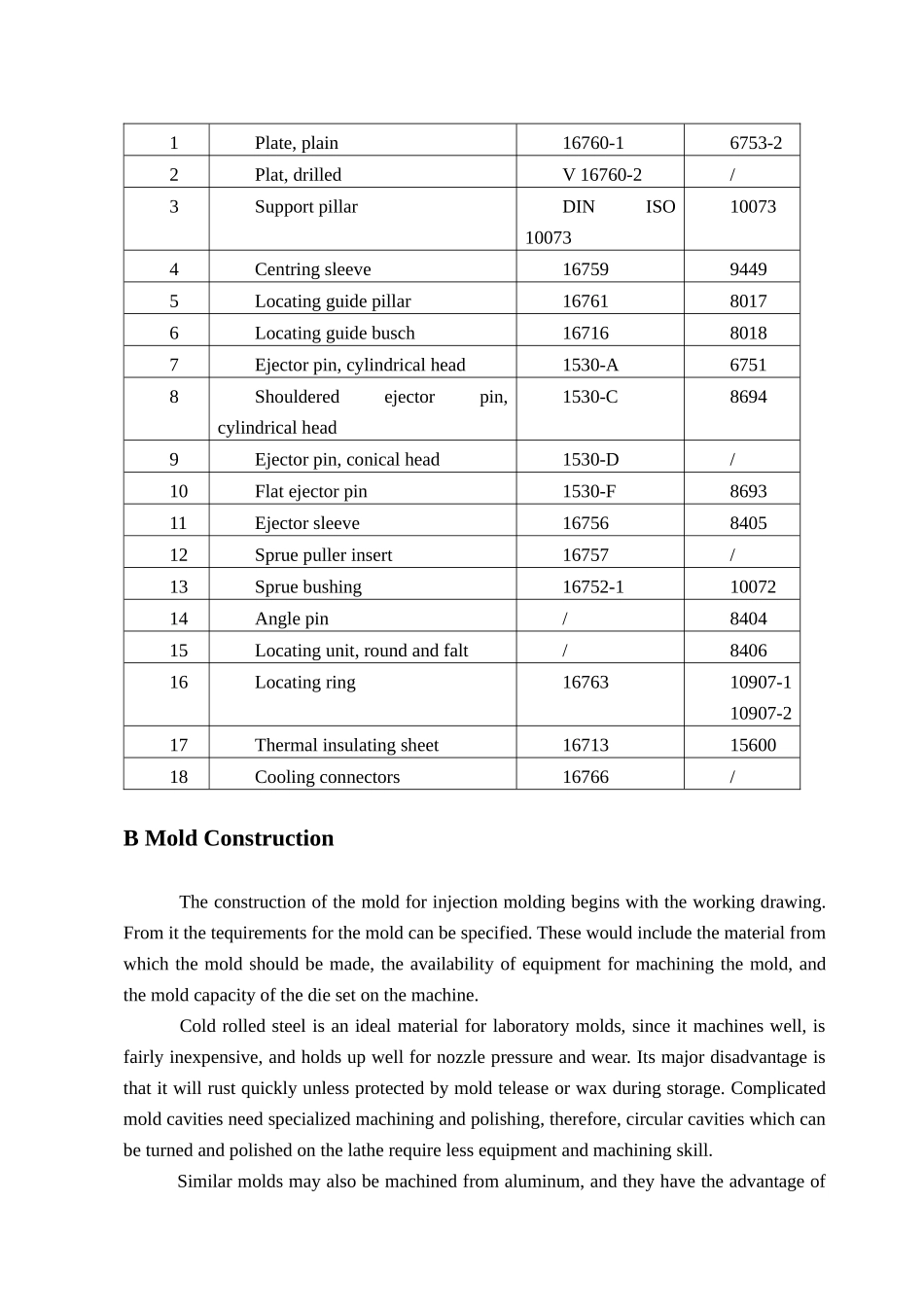

常州工学院毕业设计(论文)外文文献学院机电学院专业班级10成型一学生姓名高丽君指导教师陈怀国A.MoldComponetsMoldsusedininjectionmoldingconsistoftwohalves;onestationaryandonemovable.Thestationaryhalfisfasteneddirectlytothestationaryplatenandisindirectcontactwiththenozzleoftheinjectionunitduringoperation.Themovablehalfofthemoldissecuredtothemovableplatenandusuallycontainstheejectormechanism.Therearemanypossiblemolddesigna,includingmultiplepiecemoldsforcomplicatedparts.Onproductionmoldingequipmentmanyarticlesmaybeshotatthesametimebytheuseofmultiplecavitymolds.Theuseofabalancedrunnersystemcarriestheplasticfromthespruetoeachindividualcavity.Atthispointhematerialpassesthroughagateintothecavity.Thegateisarestriction,smallerthentherunner,toprovideforevenfillingofthemoldcavityandtoallowtheproductstobeeasilyremovedformtherunnersystem.Withmostinjectionmoldingsystem,thearticlescanbesnappedawayfromtherunnerorspruewithoutadditionaltrimming.Prouductsthathavebeeninjectionmoldedcanusuallybeidentifiedbyfindingwherethegatewasbrokenoff.Thegatewillusuallybelocatedattheedgeorpartinglineofanobjectorinthecenterofcylindricalproduct.Moldsareexpensive,asarethemachines.Yet,oncetheproducthasbeendesigned,moldsmade,andproductionstared,articlescanbeproducedinquantityatlowcost.Virtuallyallthermoplasticscanbeinjectionmoldedthroughvariationsinmoldandmachinedesign.Mold(anddie)partsthataremass-producedandstandardizedinshapeanddimensionarereferredtoas“standards”(or“standardparts”).Specializedoperatorsofmillingmachines,lathes,lathes,electronicdischargemachining(EDN)equipmentandgrindersproducemoldcomponentsindependentlyofeachother,followingdetaiedmoldpartdrawings.Finally,alltheseitemscometogetherwiththestandardmoldbaseandhardwareandareassembledbythemoldmaker.Today,standardcomponentsforthemoldmakingindustryaremarketedbyanumberofcompanies.Fig.3.1.1illustratethestandardcomponentsforMolds.Table3.1.1Statusofstandardization(1998)componentsforCompression,Injection,andDie-CastMoldPos.No.DenominationStandardDINISO1Plate,plain16760-16753-22Plat,drilledV16760-2/3SupportpillarDINISO10073100734Centringsleeve1675994495Locatingguidepillar1676180176Locatingguidebusch1671680187Ejectorpin,cylindricalhead1530-A67518Shoulderedejectorpin,cylindricalhead1530-C86949Ejectorpin,conicalhead1530-D/10Flatejectorpin1530-F869311Ejectorsleeve16756840512Spruepullerinsert16757/13Spruebushing16752-11007214Anglepin/840415Locatingunit,roundandfalt/840616Locatingring1676310907-110907-217Thermalinsulatingsheet167131560018Coolingconnectors16766/BMoldConstructionTheconstructionofthemoldforinjectionmoldingbeginswiththeworkingdrawing.Fromitthetequirementsforthemoldcanbespecified.Thesewouldincludethematerialfromwhichthemoldshouldbemade,theavailabilityofequipmentformachiningthemold,andthemoldcapacityofthediesetonthemachine.Coldrolledsteelisanidealmaterialforlaboratorymolds,sinceitmachineswell,isfairlyinexpensive,andholdsupwellfornozzlepressureandwear.Itsmajordisadvantageisthatitwillrustquicklyunlessprotectedbymoldteleaseorwaxduringstorage.Complicatedmoldcavitiesneedspecializedmachiningandpolishing,therefore,circularcavitieswhichcanbeturnedandpolishedonthelatherequirelessequipmentandmachiningskill.Similarmoldsmayalsobemachinedfromaluminum,andtheyhavetheadvantageofnotrusting.Excessiveweardevelopsonthesprueduetothehighnozzlepressureonthesoftaluminum,butt...