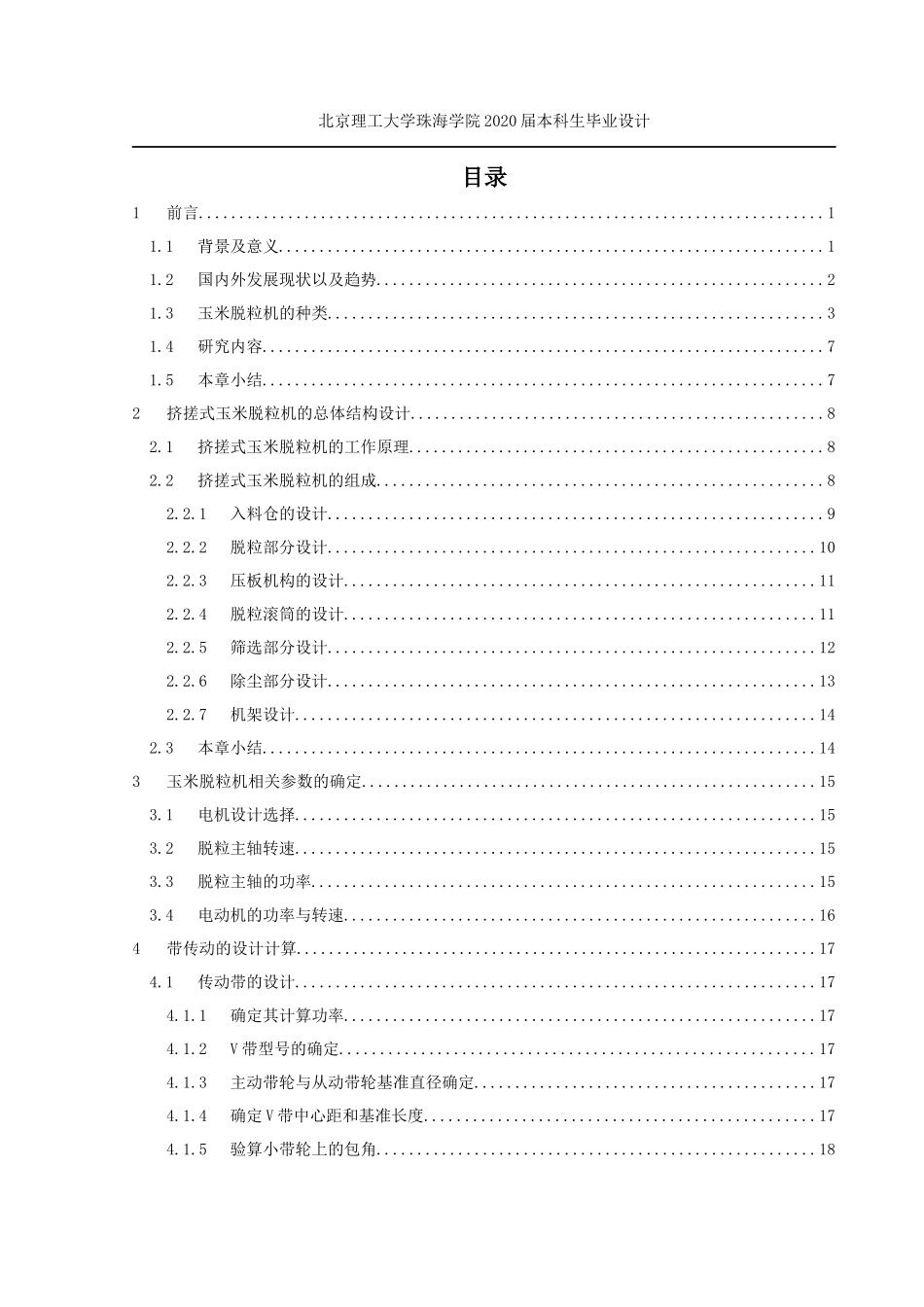

玉米脱粒机——硬件设计摘要针对大型玉米脱粒机设备结构复杂、面积大、价格高,不适合小规模农民使用的问题,提出一种新型的玉米脱粒机的设计。本文设计了玉米脱粒的机构、电机的选择、带轮的结构设计的内容。以及运用三维软件绘画玉米脱粒机,用cad绘制二维图。我们先从玉米脱粒机的脱粒原理来研究,采用挤搓式玉米脱粒装置,通过玉米果穗从入料口到出料口和排芯口一体化,减少玉米果穗在脱粒装置的工作时间,进而提高了生产效率。由调节格栅凹版来调整脱粒间隙,使脱粒间隙能随玉米特性而调整。再通过由排芯区装有压板机构,调节配铁控制压板,让玉米果穗完全脱粒才会顶开压板,进而提高了脱净率。关键词:挤搓式玉米脱粒机;结构设计;机械结构;压板机构;调节格栅北京理工大学珠海学院2020届本科生毕业设计Cornthresher--hardwaredesignAbstractAimingattheproblemoflarge-scalecornthresherequipmentwithcomplexstructure,largeareaandhighprice,whichisnotsuitableforsmall-scalefarmers,anewtypeofcornthresherdesignisproposed.Thisarticledesignsthecornthreshingmechanism,thechoiceofmotor,andthestructuraldesignofthepulley.Andusethree-dimensionalsoftwaretodrawcornthresher,usecadtodrawtwo-dimensionalmap.Wefirststudyfromthethreshingprincipleofthecornthresher.Usingthesqueezetypecornthreshingdevice,throughtheintegrationofthecornearfromtheinlettotheoutletandthecoreoutlet,theworkingtimeofthecornearinthethreshingdeviceisreduced,andthusimprovedProductionefficiency.Thethreshinggapcanbeadjustedbyadjustingthegridgravureandcontrolledbyamotor,sothatthethreshinggapcanbeadjustedaccordingtothecharacteristicsofcorn.Then,thepressureplatemechanismisinstalledinthecorerowarea,andtheirondistributionisadjustedtohowtocontrolthepressureplate,sothatthecornearsarecompletelythreshedbeforethepressureplateisopened,therebyincreasingtheremovalrate.Keywords:Squeezeandtwistcornsheller;Structuraldesign;Mechanicalstructure;Pressingmechanism;Adjustthegrille北京理工大学珠海学院2020届本科生毕业设计目录1前言.............................................................................11.1背景及意义...................................................................11.2国内外发展现状以及趋势.......................................................21.3玉米脱粒机的种类.............................................................31.4研究内容.....................................................................71.5本章小结.....................................................................72挤搓式玉米脱粒机的总体结构设计...................................................82.1挤搓式玉米脱粒机的工作原理...................................................82.2挤搓式玉米脱粒机的组成.......................................................82.2.1入料仓的设计.............................................................92.2.2脱粒部分设计............................................................102.2.3压板机构的设计..........................................................112.2.4脱粒滚筒的设计..........................................................112.2.5筛选部分设计............................................................122.2.6除尘部分设计............................................................132.2.7机架设计................................................................142.3本章小结....................................................................143玉米脱粒机相关参数的确定........................................................153.1电机设计选择.............................................