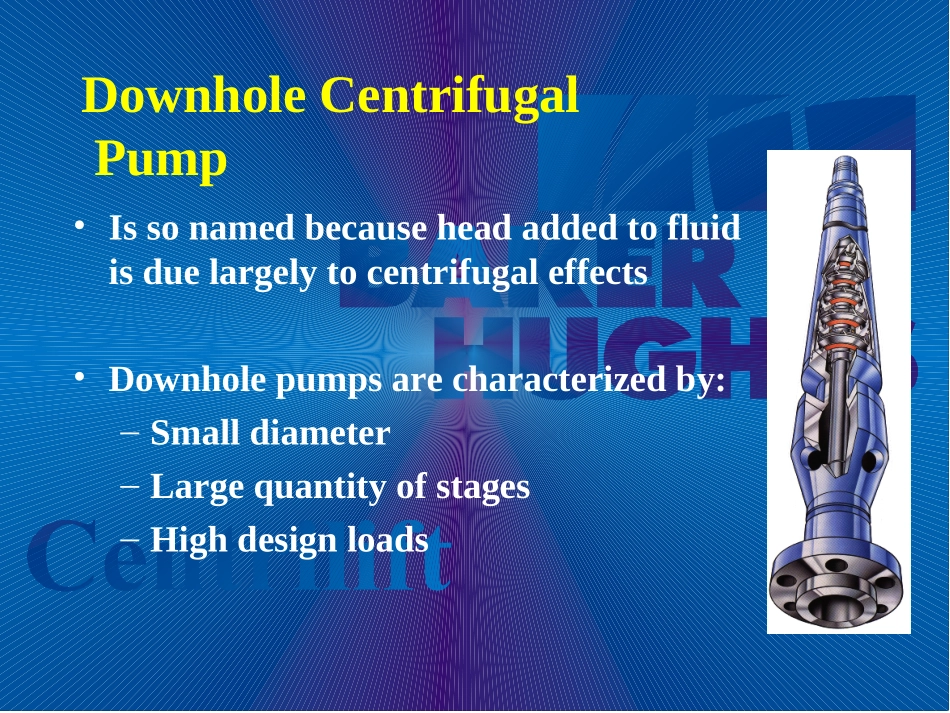

CentriliftBasicsAguidetoCentriliftESPSystemsCentrilift,TheSystem•Consistentlysettheindustrystandard•Allthetechnologytoprovidethecompletesystem•Withthesystemapproachtotechnology,wearebetterabletocontrolthequalityandreliabilityofproductsandservicesDownholeCentrifugalPump•Issonamedbecauseheadaddedtofluidisduelargelytocentrifugaleffects•Downholepumpsarecharacterizedby:–Smalldiameter–Largequantityofstages–HighdesignloadsDownholeCentrifugalPump•Isnormallydrivenbyatwo-polesubmersiblemotorattypicaloperatingspeedsofapproximately3,600rpmDownholeCentrifugalPump•Maybedrivenatotherspeedseitherduetopowersourceorintentionallytomodifyperformance•Flow=ƒ(rpm)=ƒ(frequency)•Head=ƒ(rpm2)=ƒ(frequency2)•Power=ƒ(rpm3)=ƒ(frequency3)PumpStage•WorksbytransferringenergyprovidedbydrivertofluidtobemovedGasHandlingESPCAPABILITIESONGASSYCRUDE%GASTOFLUIDRATIO(GFR)STANDARDPUMPRadialImpellerSTANDARDPUMPMixedFlowImpellerTAPEREDPUMPPUMPw/SeparatorPUMPw/TandemSeparator020406080100GasSeparation•Usedinapplicationswherefreegascausesinterferencewithpumpperformance•Separatesomeoffreegasfromfluidstreamenteringpumptoimprovepump’sperformance•Gasseparatormethodsinclude:–Wellboreshrouding–Reverseflowintakes–Centrifugeseparators•Speciallydesignedrotatingchamberactsasacentrifuge•Forcesheavierfluidtooutsideandallowsfreegastomigratetocenterofchamber•Twostreamsarephysicallyseparatedattop•Liquidrichstreamisportedinternallytopumpinlet•GasrichstreamisventedtocasingannulusRotaryGasSeparatorSealSection•Islocatedbetweenpumpandmotor•MainfunctionistoprotectmotorSealSection•Protectsmotorfromcontaminationbywellfluid•Absorbsthrustfrompump•EqualizespressurebetweenwellboreandmotorSealSection•Equalizespressureandpreventswellfluidfromenteringmotorbyusing:–Mechanicalseals–Abladdersystem–AlabyrinthsystemSubmersibleMotor•Isoilfilled•Isatwo-pole,three-phase,3600RPMdesign•Motorcomponentsdesignedtowithstand500oFtemperaturesSubmersibleMotor•Motorcoolingisachievedby:–Internaloilcirculation–FlowofwellfluidalongoutsideskinVariableSpeedDrive•Simpletooperate•Multiplefunctions•Mostwidelyusedforoilfieldapplication•AvailableinNemaIorIIIEnclosuresPumpfailuresinabrasiveenvironmentsarecausedby:1.Excessiveradialbearingwear•especiallycriticalintopandbottomofpumpwhereresultingvibrationistransferredtothemechanicalsealsorbetweencoupledunits•lossofradialsupportthroughoutpumpresultsinvibrationandoperationalinstability2.Excessivestagedownthrustwear•cancutthroughimpellershroud,causinghydraulicperformancedegradationandcanblockflowpassageways•labandfielddatademonstratesthisfailuremodeisaclosesecondtoradialbearingfailure3.Erosivewearinflowpassageways•hydraulicperformanceslowlydegradesovertime•longertermfailuremodethandownthrustandradialbearingfailure•generallyonlyobservedinhighlyabrasiveenvironmentsPumpAbrasiveWearARMPumpLine11ModuleconsistsofstandardstageslocatedinintermediatepositionsaboveanARstage.ThrustistransferredtotheARinsertsetthroughadjacentimpellerhubswithinthemodule.Patenteddesignprovidesenhanceddownthrustandradialsupportwearprotectionineverymodule2233Apremiumpumplineformildtoaggressivewellconditionsthatgivesenhancedradialandthrustwearprotection.ARCoatedStages•Centriliftalsouse“Pumpguard”coating(polymer)onstagestoimprovestagewearcharacteristicsandincreaserunlife•A“PumpguardI”coatingwouldtypic...