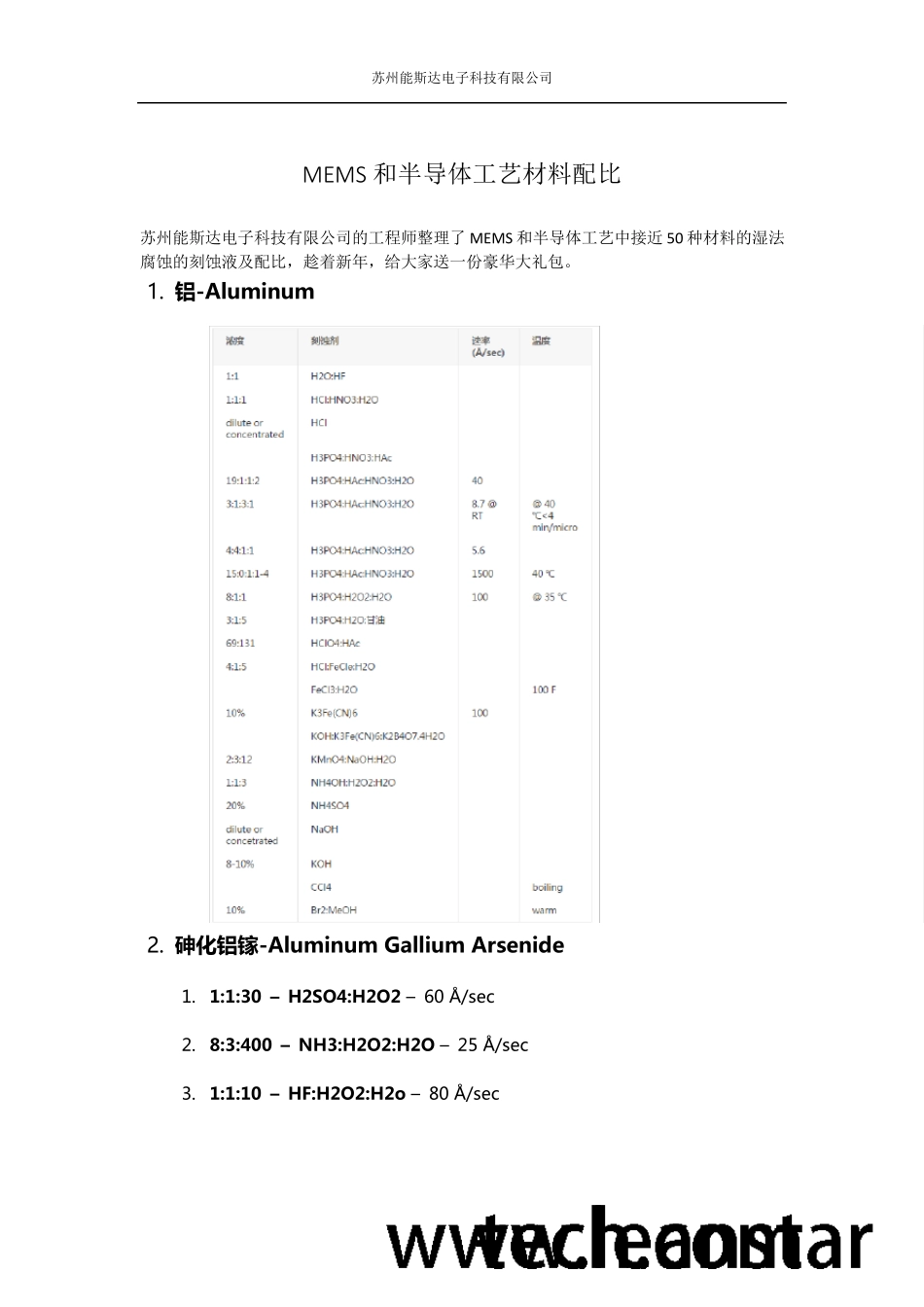

苏州能斯达电子科技有限公司 MEMS和半导体工艺材料配比 苏州能斯达电子科技有限公司的工程师整理了MEMS和半导体工艺中接近50 种材料的湿法腐蚀的刻蚀液及配比,趁着新年,给大家送一份豪华大礼包。 1. 铝 -Aluminum 2. 砷 化铝 镓 -Aluminum Gallium Arsenide 1. 1:1:30 – H2SO4:H2O2 – 60 Å /sec 2. 8:3:400 – NH3:H2O2:H2O – 25 Å /sec 3. 1:1:10 – HF:H2O2:H2o – 80 Å /sec 苏州能斯达电子科技有限公司 3. 三氧 化 二 铝 /铝 /蓝 宝 石 -Aluminum Trioxide / Alumina / Sapphire 1. 1:1:3 – NH4OH:H2O2:H2O – 80 ℃ 2. 10% Br2:MeOH 3. 7ml:4g – H3PO:Cr2O3 4. 锑 -Antimony 1. 1:1:1 – HCl:HNO3:H2O 2. 90:10:1 – H2O:HNO3:HF 3. 3:3:1:1 – H3PO4:HNO3:CH3COOH:H2O <<3min/1000A 50℃ 5. 铋 -Bismuth 1. 10:1 – H2O:HCl 6. 黄 铜 -Brass 1. FeCl3 2. 20% NHSO5 7. 青 铜 -Bronze 1. 1% CrO3 8. 碳 -Carbon 1. H3PO4:CrO3:NaCN 2. 50% KOH (or NaOH) – boiling 3. HNO3 concentrated 4. H2SO4 concentrated 5. 3:1 – H2SO4:H2O2 苏州能斯达电子科技有限公司 9. 铬 -Chromium 1. 2:3:12 KMnO4:NaOH:H2O 2. 3:1 – H2O:H2O2 3. HCl concentrated and dilute 4. 3:1 – HCl:H2O2 5. 2:1 – FeCl:HCl 6. Cyantek CR-7s (Perchloric based) 7 min/micron (24A/s new ) 7. 1:1 – HCl:glycerine 12min/micron after depassivation 8. 1:3 – [50gNaOH+100mlH2O]:[30g K3Fe(CN)6+100mlH2O] 1hr/micron 10. 钴-Cobalt 1. 1:1 H2O:HNO3 2. 3:1 HCl:H2O2 11. 铜-Copper 1. 30% FeCl3 saturated solution 2. 20% KCN 3. 1:5 – H2O:HNO3 4. HNO3 concentrated and dilute 5. 1:1 – NH4OH:H2O2 6. 1:20 – HNO3:H2O2 7. 4:1 – NH3:H2O2 8. 1:1:1 – H3PO4:HNO3:HAc 苏州能斯达电子科技有限公司 9. 5ml:5ml:4g:1:90ml – HNO3:H2SO4:CrO3:NH4Cl:H2O 10. 4:1:5 – HCL:FeCl3:H2O 12. 环 氧 树 脂 -Epoxies 1. General Polymer Etch 2. 5:1 – NH4OH:H2O2 – 120 ℃ 3. Gold Epoxy 4. 3:1:10 HNO3:HCl:H2O 5. Silver Epoxy 6. 1:3 – HF:HNO3 7. Aluminum Epo...