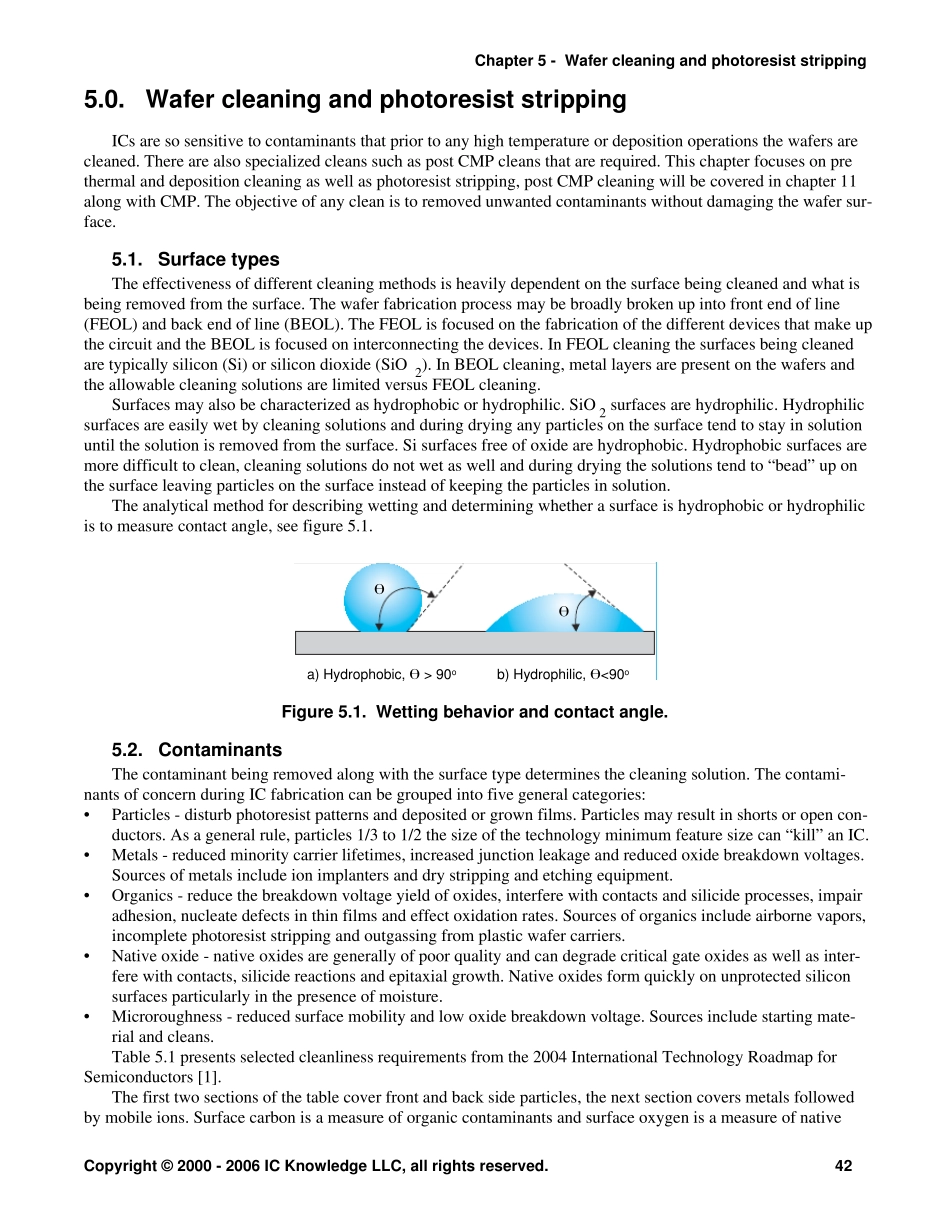

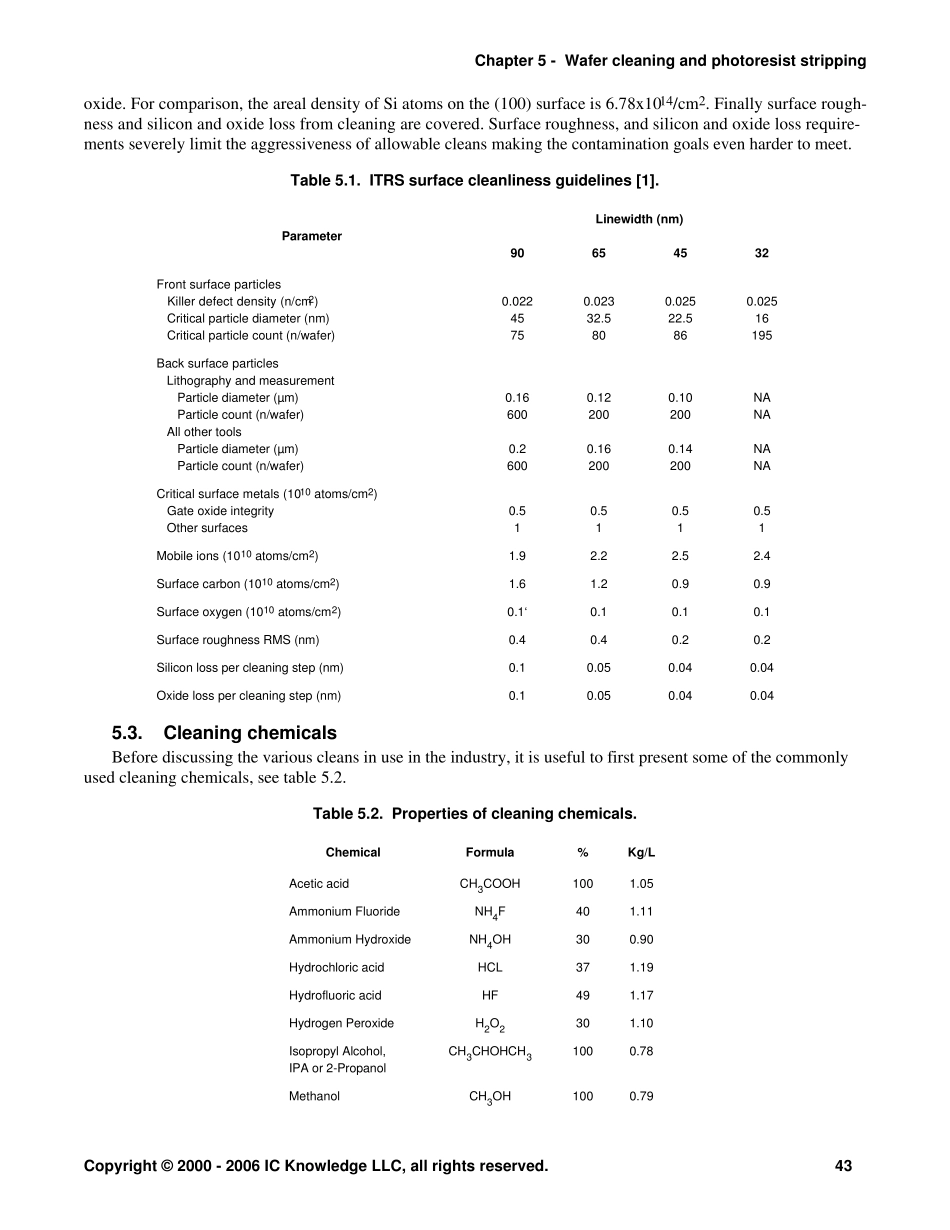

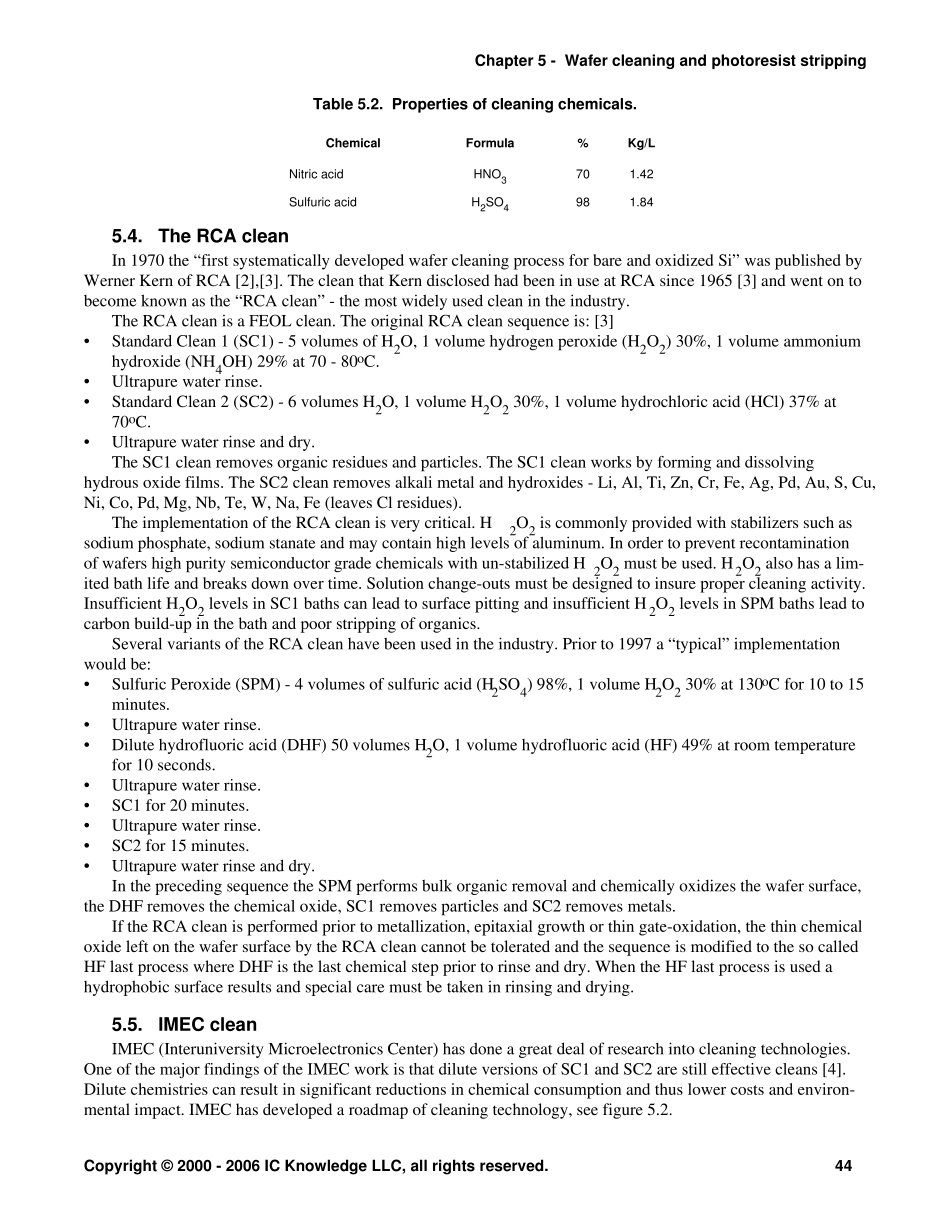

Chapter 5 - Wafer cleaning and photoresist strippingCopyright © 2000 - 2006 IC Knowledge LLC, all rights reserved.425.0. Wafer cleaning and photoresist strippingICs are so sensitive to contaminants that prior to any high temperature or deposition operations the wafers are cleaned. There are also specialized cleans such as post CMP cleans that are required. This chapter focuses on pre thermal and deposition cleaning as well as photoresist stripping, post CMP cleaning will be covered in chapter 11 along with CMP. The objective of any clean is to removed unwanted contaminants without damaging the wafer sur-face.5.1. Surface typesThe effectiveness of different cleaning methods is heavily dependent on the surface being cleaned and what is being removed from the surface. The wafer fabrication process may be broadly broken up into front end of line (FEOL) and back end of line (BEOL). The FEOL is focused on the fabrication of the different devices that make up the circuit and the BEOL is focused on interconnecting the devices. In FEOL cleaning the surfaces being cleaned are typically silicon (Si) or silicon dioxide (SiO 2). In BEOL cleaning, metal layers are present on the wafers and the allowable cleaning solutions are limited versus FEOL cleaning.Surfaces may also be characterized as hydrophobic or hydrophilic. SiO 2 surfaces are hydrophilic. Hydrophilic surfaces are easily wet by cleaning solutions and during drying any particles on the surface tend to stay in solution until the solution is removed from the surface. Si surfaces free of oxide are hydrophobic. Hydrophobic surfaces are more difficult to clean, cleaning solutions do not wet as well and during drying the solutions tend to “bead” up on ...