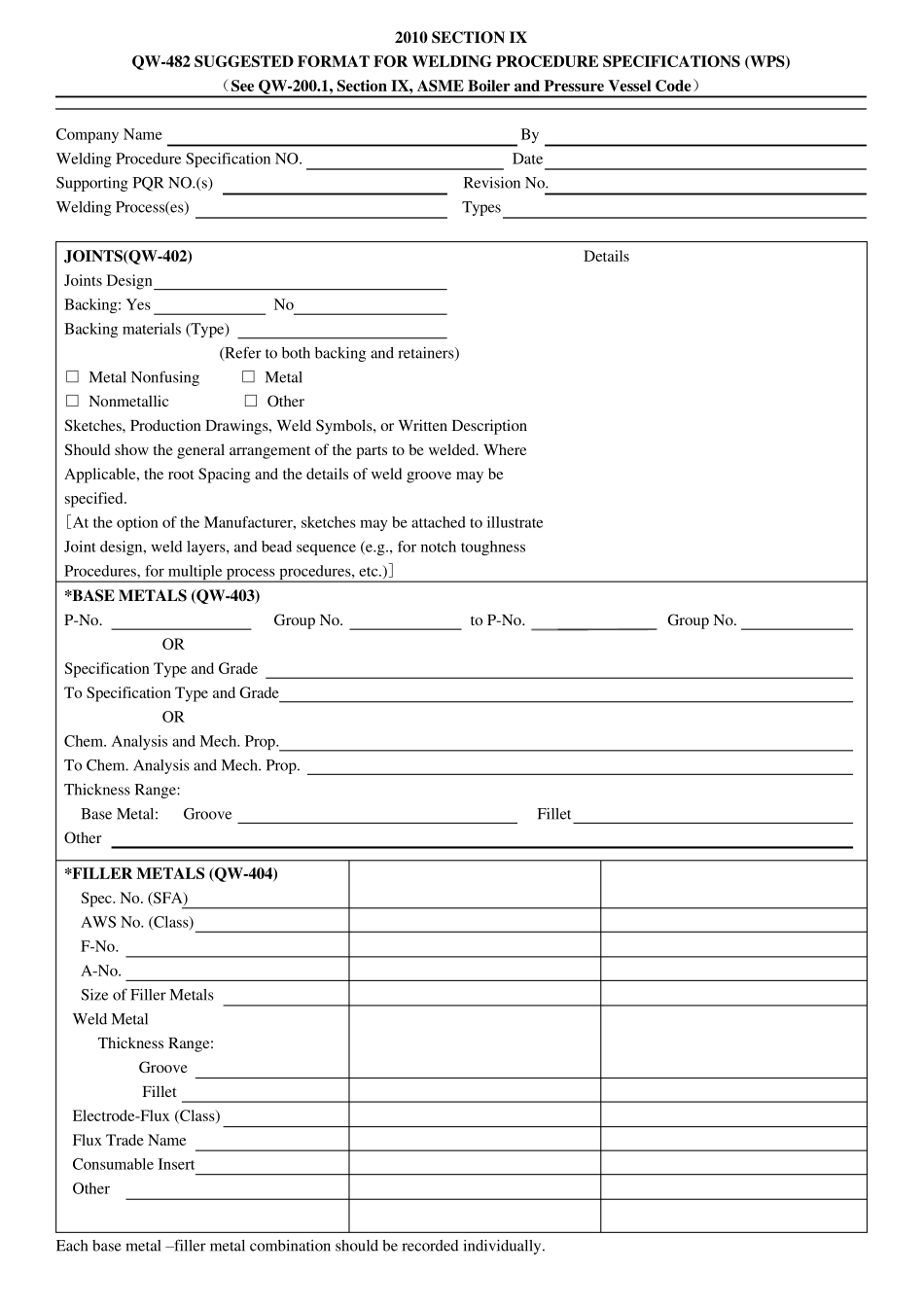

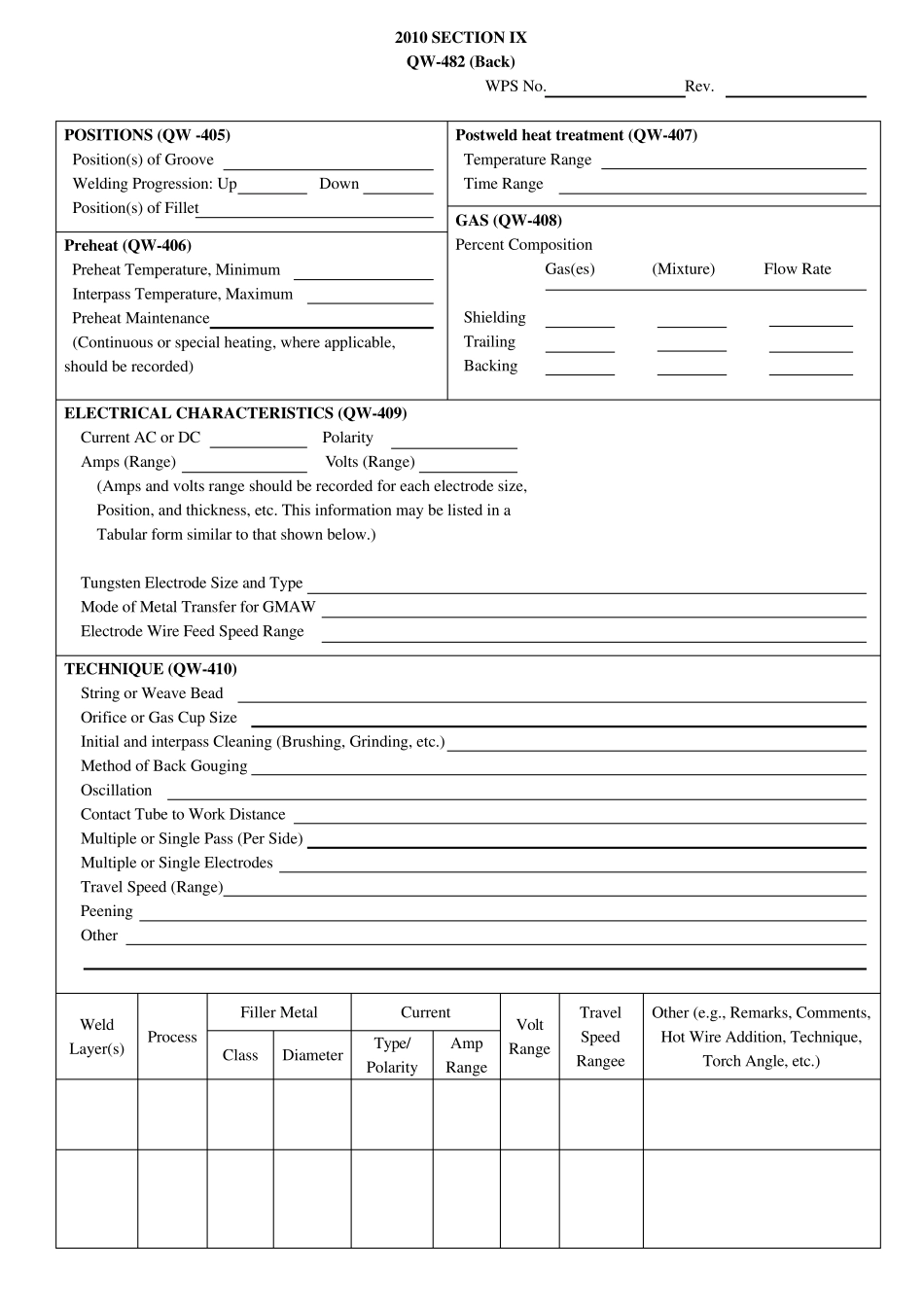

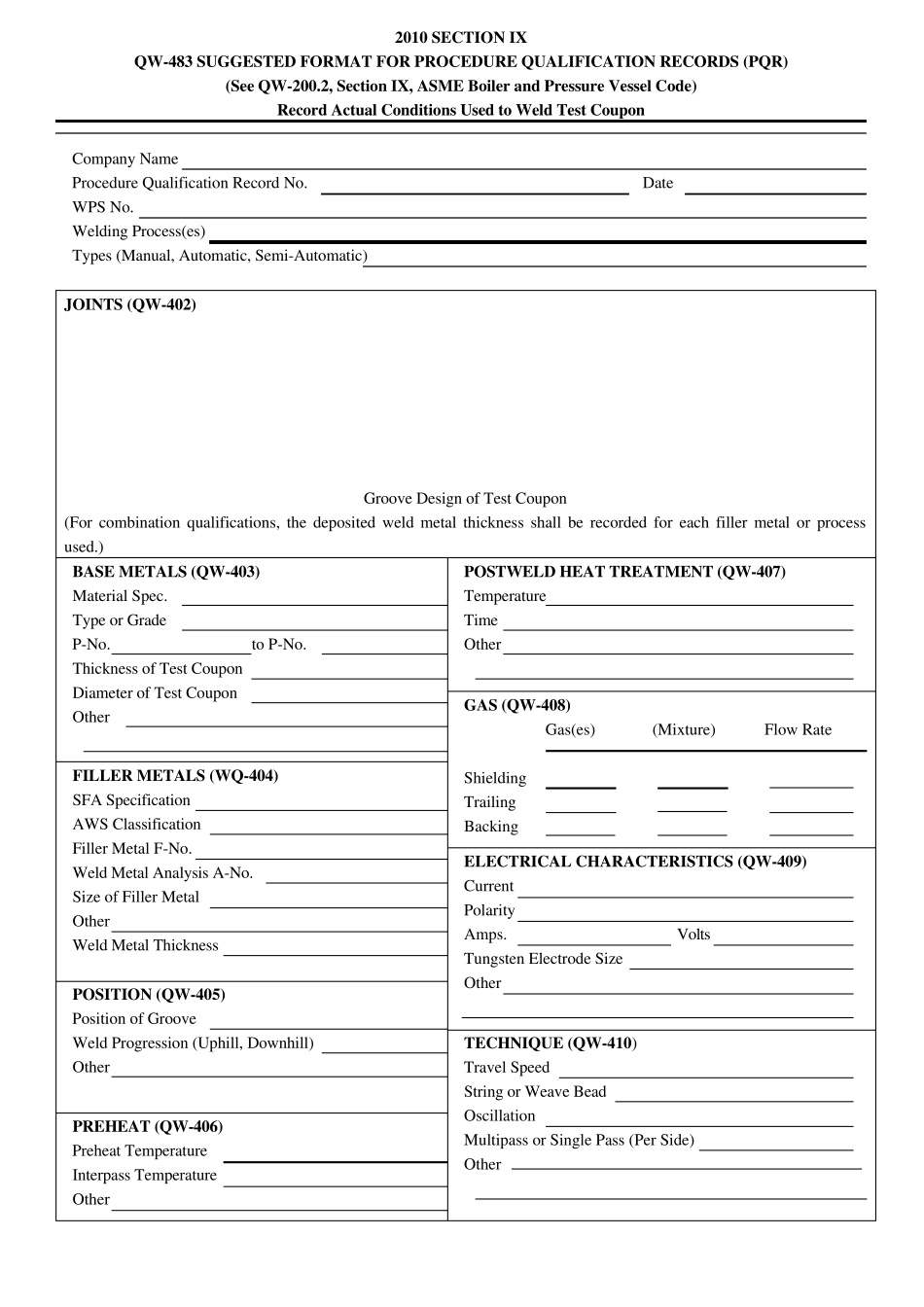

2010 SECTION IX QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressu re Vessel Code) Company Name By Welding Procedure Specification NO. Date Supporting PQR NO.(s) Revision No. Welding Process(es) Types JOINTS(QW-402) Details Joints Design Backing: Yes No Backing materials (Type) (Refer to both backing and retainers) □ Metal Nonfusing □ Metal □ Nonmetallic □ Other Sketches, Production Drawings, Weld Symbols, or Written Description Should show the general arrangement of the parts to be welded. Where Applicable, the root Spacing and the details of weld groove may be specified. [At the option of the Manufacturer, sketches may be attached to illustrate Joint design, weld layers, and bead sequence (e.g., for notch toughness Procedures, for multiple process procedures, etc.)] *BASE METALS (QW-403) P-No. Group No. to P-No. Group No. OR Specification Type and Grade To Specification Type and Grade OR Chem. Analysis and Mech. Prop. To Chem. Analysis and Mech. Prop. Thickness Range: Base Metal: Groove Fillet Other *FILLER METALS (QW-404) Spec. No. (SFA) AWS No. (Class) F-No. A-No. Size of Filler Metals Weld Metal Thickness Range: Groove Fillet Electrode-Flux (Class) Flux Trade Name Consumable Insert Other Each base metal –filler metal combination should be recorded individually. 2010 SECTION IX QW-482 (Back) WPS No. Rev. POSITIONS (QW -405) Position(s) of Groove Welding Progression: Up Down Position(s) of Fillet Postw eld heat treatment (QW-407) Temperature Range Time Range GAS (QW-408) Percent Composition Gas(es) (Mixture) Flow Rate Shielding Trailing Backing Preheat (QW-406) Preheat Temperature, Minimum Interpass Temperature, Maximum Preheat Maintenance...