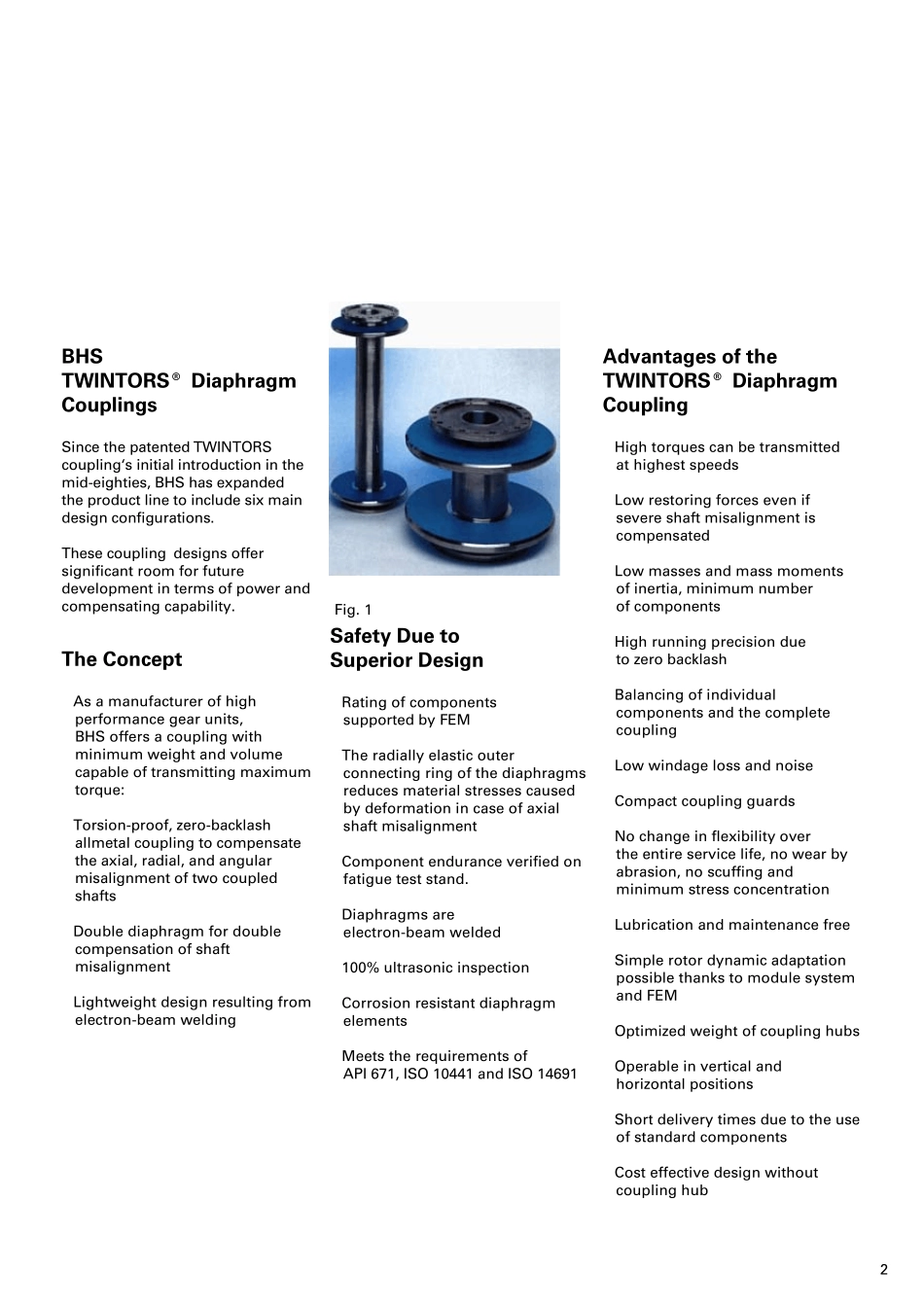

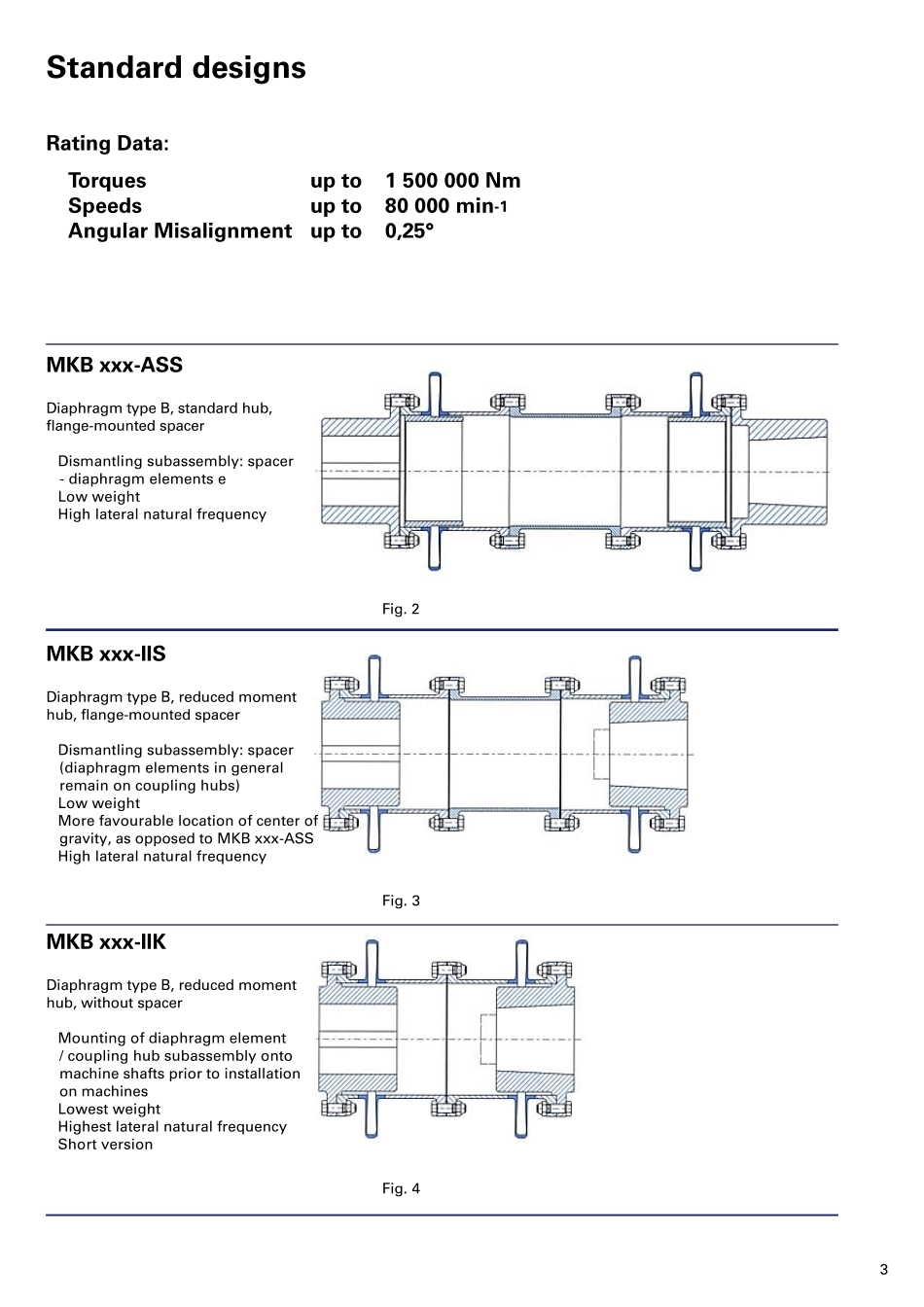

TWINTORS® Diaphragm Couplings2BHSTWINTORS® Diaphragm Couplings Since the patented TWINTORS coupling‘s initial introduction in the mid-eighties, BHS has expanded the product line to include six main design confi gurations.These coupling designs offersignifi cant room for future development in terms of power and compensating capability. The Concept As a manufacturer of high performance gear units, BHS offers a coupling with minimum weight and volume capable of transmitting maximum torque: Torsion-proof, zero-backlash allmetal coupling to compensate the axial, radial, and angular misalignment of two coupled shafts Double diaphragm for double compensation of shaft misalignment Lightweight design resulting from electron-beam welding Fig. 1 Safety Due toSuperior Design Rating of components supported by FEM The radially elastic outer connecting ring of the diaphragms reduces material stresses caused by deformation in case of axial shaft misalignment Component endurance verifi ed on fatigue test stand. Diaphragms are electron-beam welded 100% ultrasonic inspection Corrosion resistant diaphragm elements Meets the requirements of API 671, ISO 10441 and ISO 14691 Advantages of the TWINTORS® Diaphragm Coupling High torques can be transmitted at highest speeds Low restoring forces even if severe shaft misalignment is compensated Low masses and mass moments of inertia, minimum number of components High running precision due to zero backlash Balancing of individual components and the complete coupling Low windage loss and noise Compact coupling guards No change in fl exibility over the entire service life, no wear by abrasion, no scuffi ng and minimum stress concentration Lubrication and maintenance free Simple rotor dynamic adaptat...