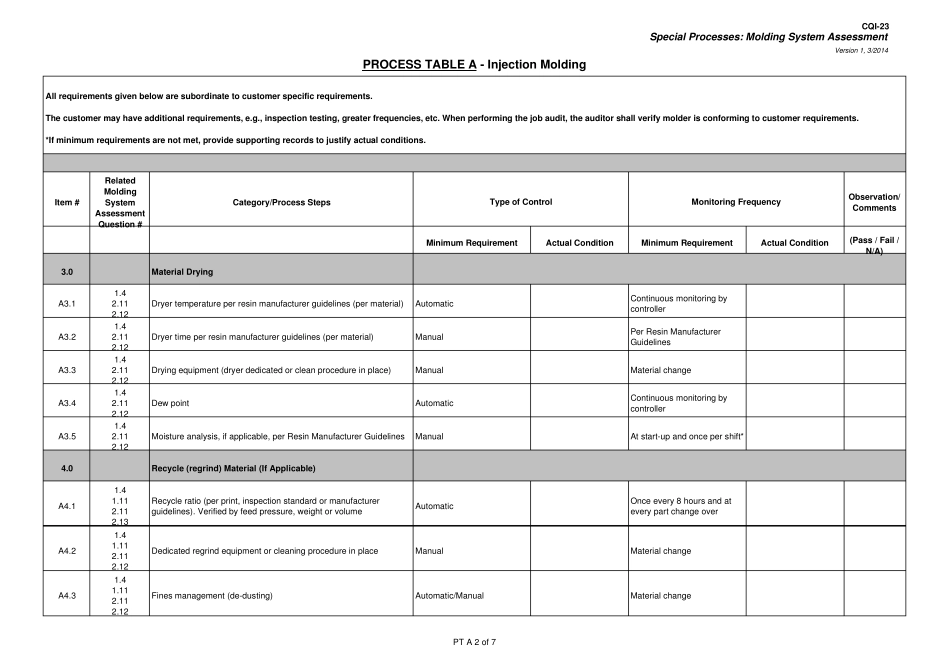

CQI-23Special Processes: Molding Sy stem AssessmentVers ion 1, 3/2014Item #RelatedMoldingSystemAssessmentQuestion #Category/Process StepsObservation/CommentsMinimum RequirementActual ConditionMinimum RequirementActual Condition(Pass / Fail /N/A)1.0Receiving InspectionA1.11.42.12.13Incoming material assessment procedure, covering onsite testing oracceptance of supplier testing, with criteria (i.e., melt flow, specificgravity).ManualOnce per lotA1.21.42.12.13Incoming components assessment procedure, covering onsitetesting or acceptance of supplier testing, with criteria (if applicable).ManualOnce per lot2.0Storage & Handling (If Applicable)A2.11.42.32.112.12Stock rotation system in place for First in/First out (FIFO) and shelf-lifeAutomatic/ManualFIFO - per LotShelf life - pull for useA2.21.42.112.12Environment temperature controlledAutomaticContinuous monitoring bycontroller or manualverification dailyA2.31.41.62.72.112.12Handling of partial containers to ensure no contamination (closedcontainer, clean environment)Automatic/ManualContinuousA2.41.41.62.72.112.12Partial container quantityAutomatic/ManualPer ContainerPROCESS TABLE A - Injection MoldingAll requirements given below are subordinate to customer specific requirements.The customer may have additional requirements, e.g., inspection testing, greater frequencies, etc. When performing the job audit, the auditor shall verify molder is conforming to customer requirements.*If minimum requirements are not met, provide supporting records to justify actual conditions.Type of ControlMonitoring FrequencyPT A 1 of 7CQI-23Special Processes: Molding Sy stem AssessmentVers ion 1, 3/2014Item #RelatedMoldingSystemAssessmentQuestion #Category/Process StepsObservation/CommentsMinimum RequirementActual ConditionMinimum RequirementActual Condition(Pass / Fail...