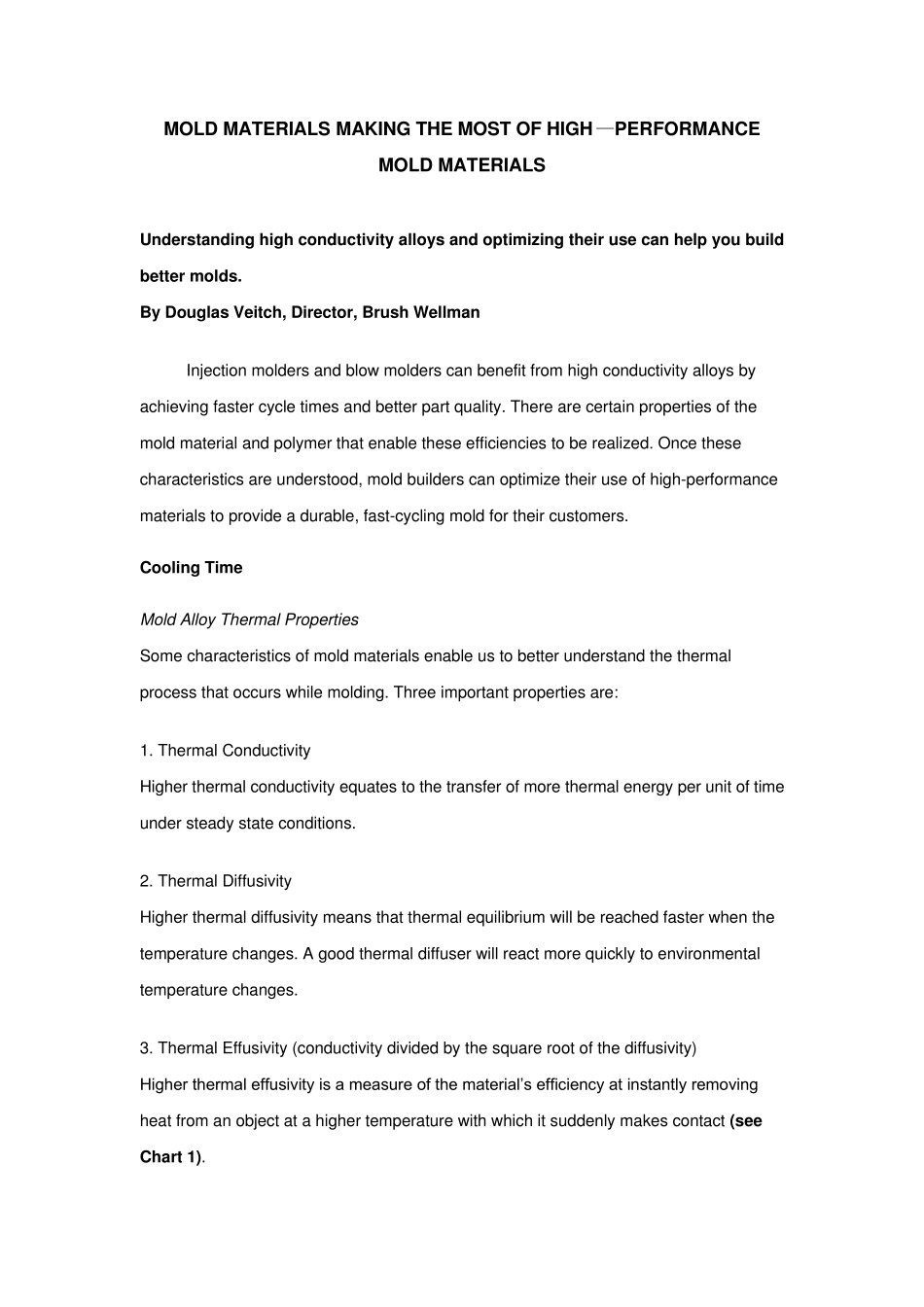

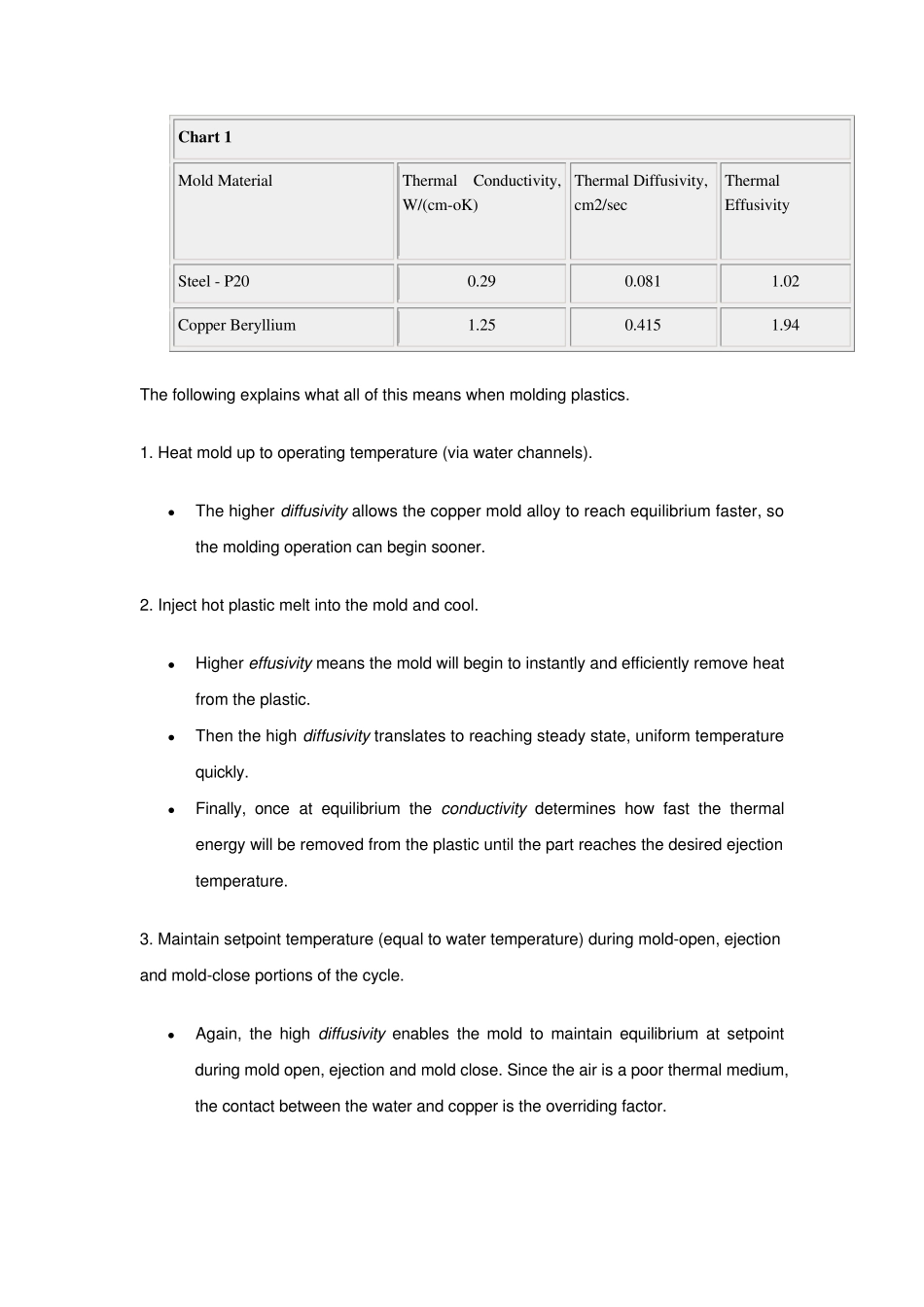

MOLD MATERIALS MAKING THE MOST OF HIGH —PERFORMANCE MOLD MATERIALS Understanding high conductivity alloys and optimizing their use can help you build better molds. By Douglas Veitch, Director, Brush Wellman Injection molders and blow molders can benefit from high conductivity alloys by achieving faster cycle times and better part quality. There are certain properties of the mold material and polymer that enable these efficiencies to be realized. Once these characteristics are understood, mold builders can optimize their use of high-performance materials to provide a durable, fast-cycling mold for their customers. Cooling Time Mold Alloy Thermal Properties Some characteristics of mold materials enable us to better understand the thermal process that occurs while molding. Three important properties are: 1. Thermal Conductivity Higher thermal conductivity equates to the transfer of more thermal energy per unit of time under steady state conditions. 2. Thermal Diffusivity Higher thermal diffusivity means that thermal equilibrium will be reached faster when the temperature changes. A good thermal diffuser will react more quickly to environmental temperature changes. 3. Thermal Effusivity (conductivity divided by the square root of the diffusivity) Higher thermal effusivity is a measure of the material’s efficiency at instantly removing heat from an object at a higher temperature with which it suddenly makes contact (see Chart 1). The following explains what all of this means when molding plastics. 1. Heat mold up to operating temperature (via water channels). • The higher diffusivity allows the copper mold alloy to reach equilibrium faster, so the molding operation can begin sooner. 2. Inject hot plastic melt int...