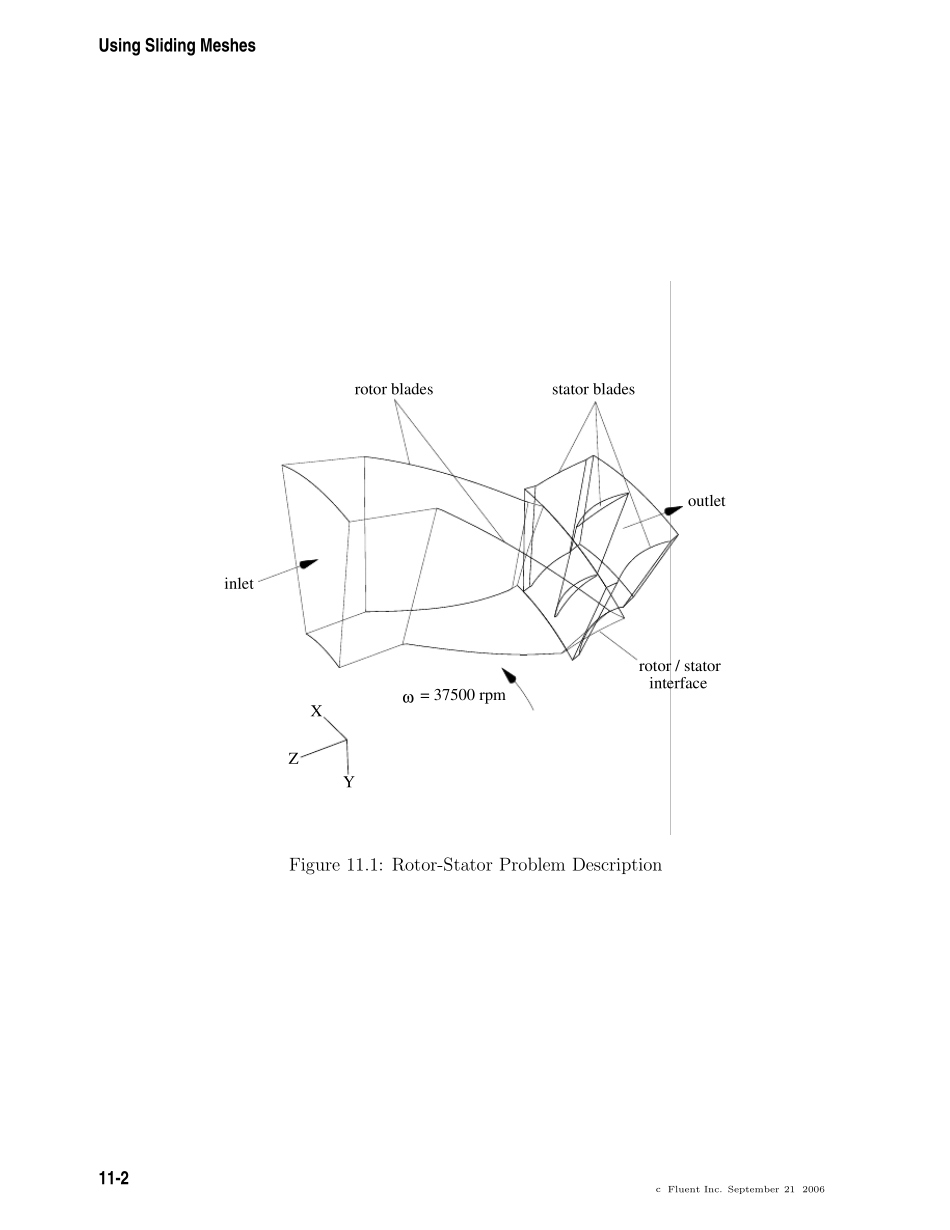

Tu torial 11.Using Sliding MeshesIntrodu ctionThe analysis of turbomachinery often involves the examination of the unsteady effectsdue to flow interaction between the stationary components and the rotating blades. Inthis tutorial, the sliding mesh capability of FLUENT is used to to analyze the unsteadyflow in an axial compressor stage. The rotor-stator interaction is modeled by allowingthe mesh associated with the rotor blade row to rotate relative to the stationary meshassociated with the stator blade row.This tutorial demonstrates how to do the following:• Create periodic zones.• Set up the unsteady solver and boundary conditions for a sliding mesh simulation.• Set up the grid interfaces for a periodic sliding mesh model.• Sample the time-dependent data and view the mean value.Prerequ isitesThis tutorial assumes that you are familiar with the menu structure in FLUENT and thatyou have completed Tutorial 1.Some steps in the setup and solution procedure will notbe shown explicitly.Problem DescriptionThe model represents a single-stage axial compressor comprised of two blade rows. Thefirst row is the rotor with 16 blades, which is operating at a rotational speed of 37,500rpm. The second row is the stator with 32 blades. The blade counts are such that thedomain is rotationally periodic, with a periodic angle of 22.5 degrees. This allows youto model only a portion of the geometry, namely, one rotor blade and two stator blades.Due to the high Reynolds number of the flow and the relative coarseness of the mesh(both blade rows are comprised of only 13,856 cells total), the analysis will employ theinviscid model, so that FLUENT is solving the Euler equations.cFlu ent Inc. September 21, 200611-1Using Sliding...