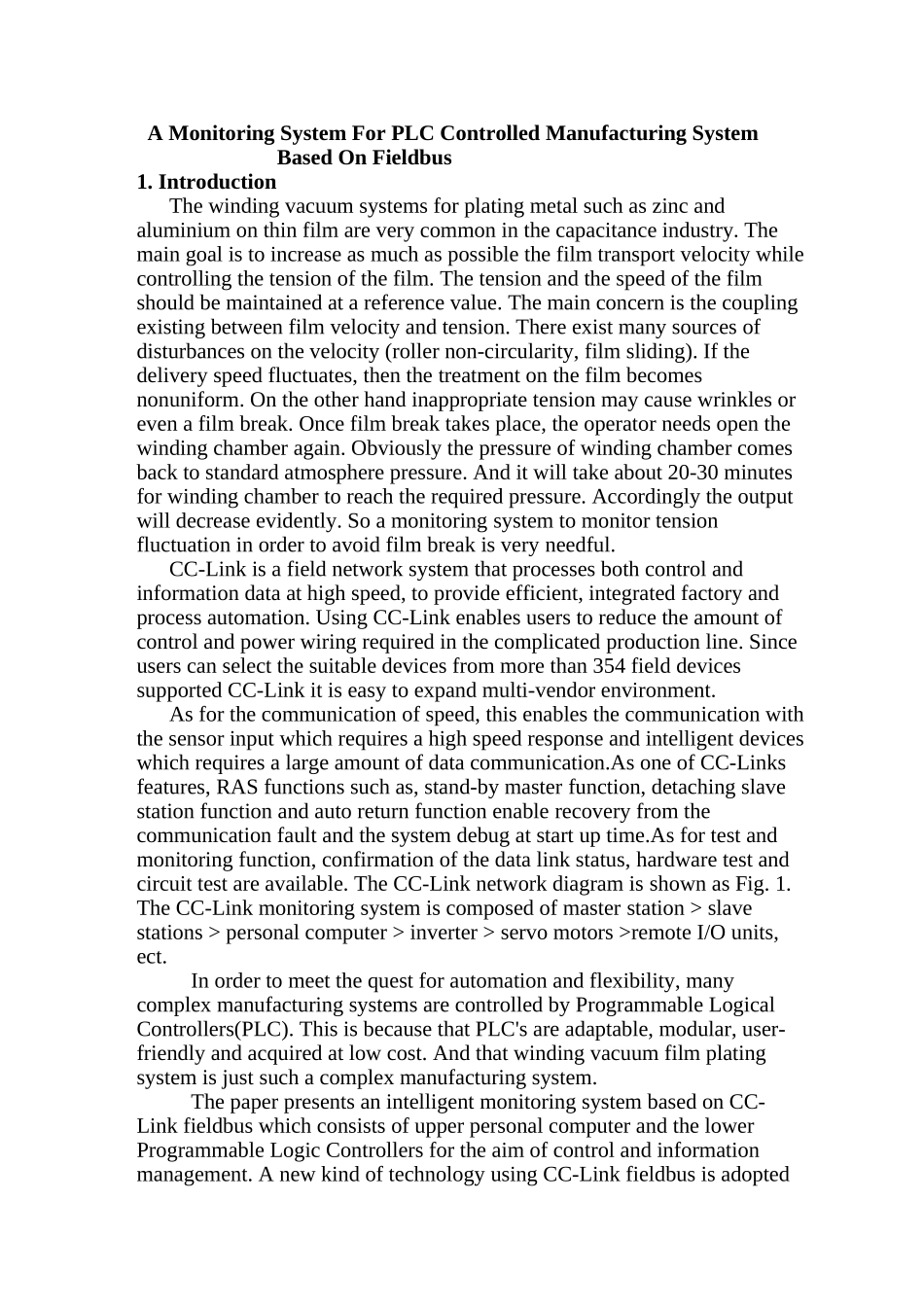

A Monitoring System For PLC Controlled Manufacturing System Based On Fieldbus1. IntroductionThe winding vacuum systems for plating metal such as zinc and aluminium on thin film are very common in the capacitance industry. The main goal is to increase as much as possible the film transport velocity while controlling the tension of the film. The tension and the speed of the film should be maintained at a reference value. The main concern is the coupling existing between film velocity and tension. There exist many sources of disturbances on the velocity (roller non-circularity, film sliding). If the delivery speed fluctuates, then the treatment on the film becomes nonuniform. On the other hand inappropriate tension may cause wrinkles or even a film break. Once film break takes place, the operator needs open thewinding chamber again. Obviously the pressure of winding chamber comes back to standard atmosphere pressure. And it will take about 20-30 minutes for winding chamber to reach the required pressure. Accordingly the output will decrease evidently. So a monitoring system to monitor tension fluctuation in order to avoid film break is very needful.CC-Link is a field network system that processes both control and information data at high speed, to provide efficient, integrated factory and process automation. Using CC-Link enables users to reduce the amount of control and power wiring required in the complicated production line. Since users can select the suitable devices from more than 354 field devicessupported CC-Link it is easy to expand multi-vendor environment.As for the communication of speed, this enables the communication with the sensor input which requires a high speed response and intelligent ...