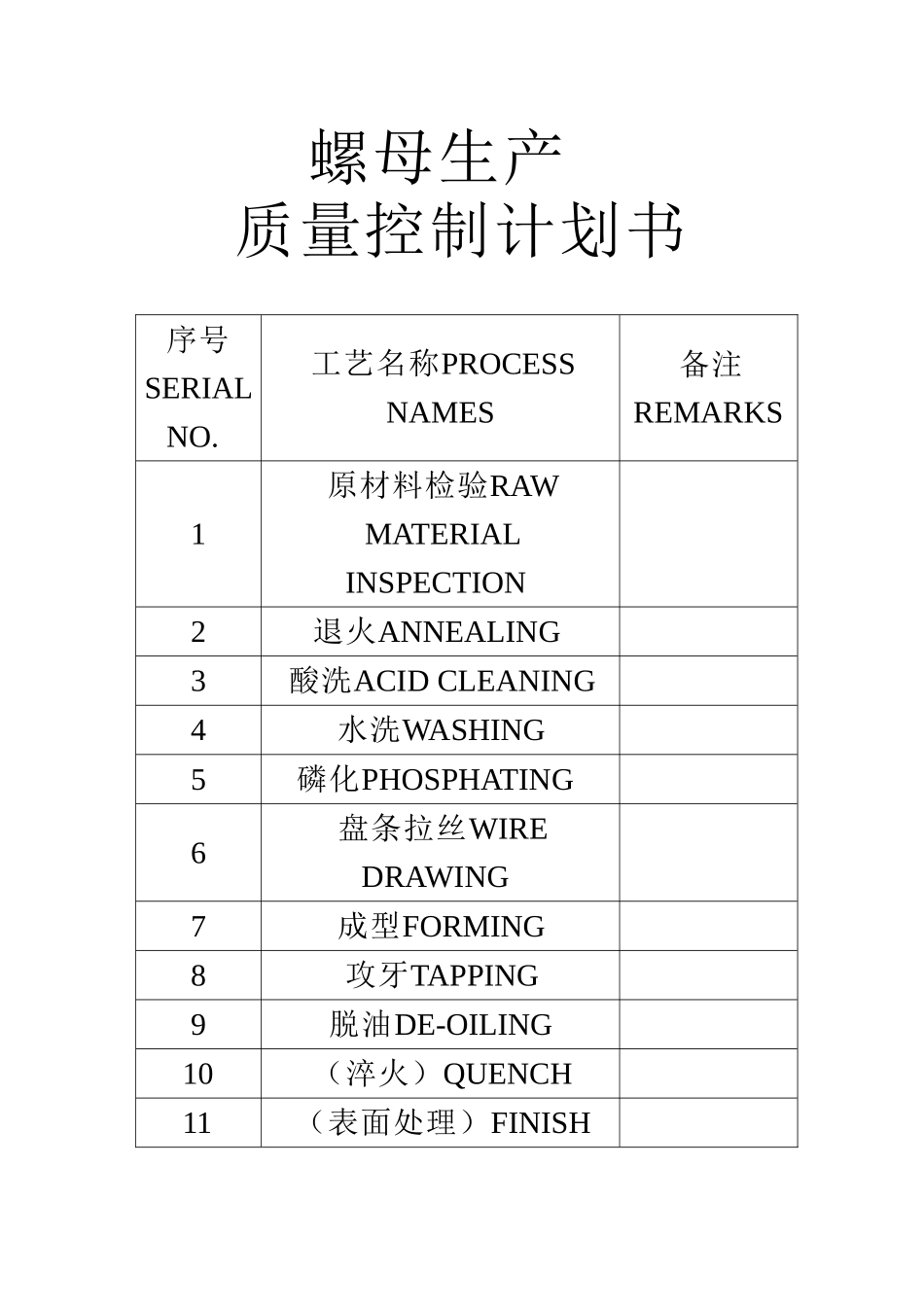

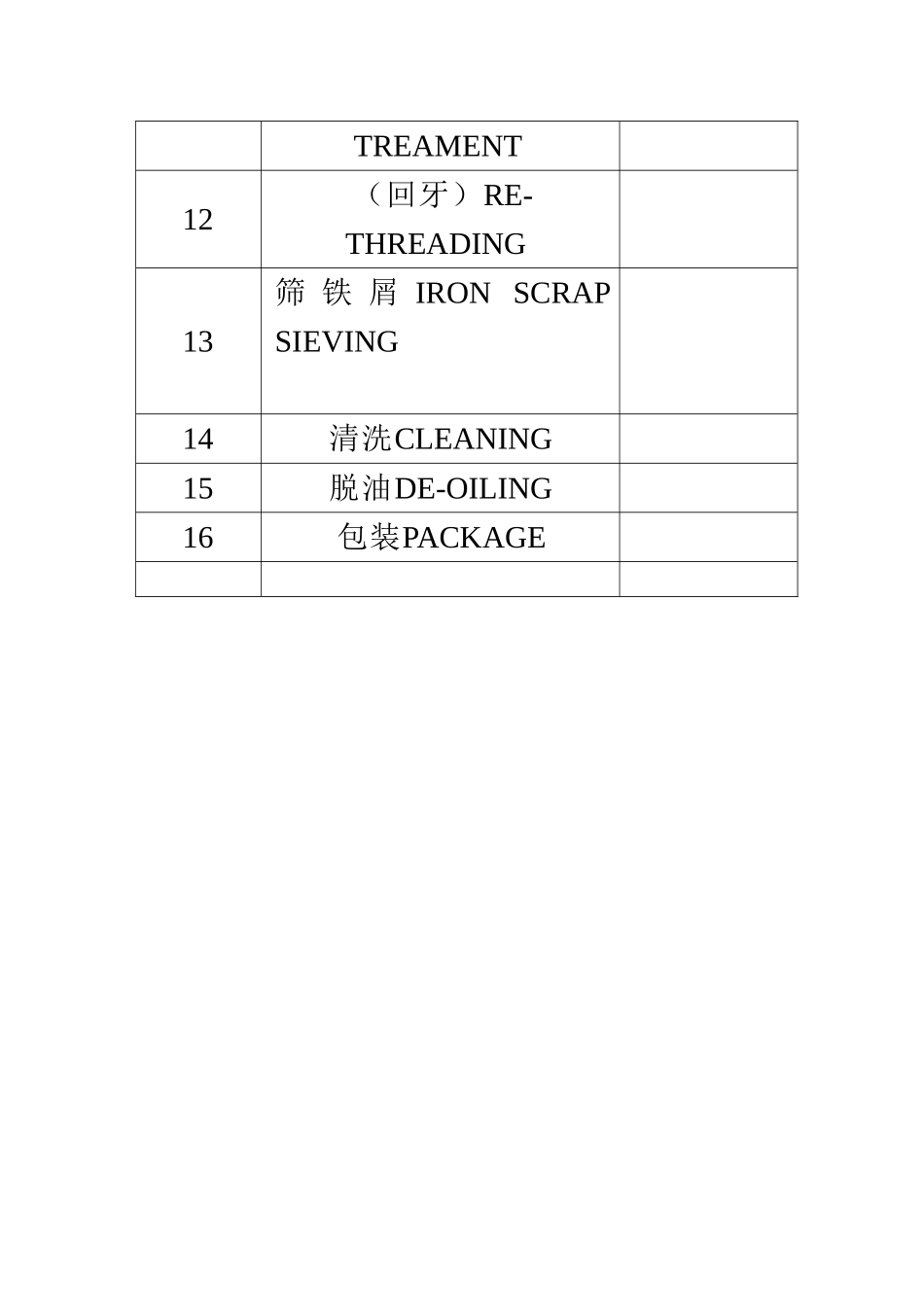

螺母生产质量控制计划书序号SERIALNO.工艺名称PROCESSNAMES备注REMARKS1原材料检验RAWMATERIALINSPECTION2退火ANNEALING3酸洗ACIDCLEANING4水洗WASHING5磷化PHOSPHATING6盘条拉丝WIREDRAWING7成型FORMING8攻牙TAPPING9脱油DE-OILING10(淬火)QUENCH11(表面处理)FINISHTREAMENT12(回牙)RE-THREADING13筛铁屑IRONSCRAPSIEVING14清洗CLEANING15脱油DE-OILING16包装PACKAGE宁波海信铁路器材有限公司NINGBOHAIXINRAILROADMATERIALCO.,LTD检验指导书INSPECTIONINSTRUCTIONS产品名称PRODUCTNAME螺母NUT材料MATERIAL第1张PAGE1共12张TOTAL12PAGES产品级别GRADE编号SERIALNO.版本VERSIONB0工序号PROCESSNO.1工序名称PROCESSNAME原材料检验RAWMATERIALINSPECTION使用设备EQUIPMENT光谱仪SPECTRUMANALYZER备注REMARKS要求REQUIREMENTS1、进厂原材料须有质量保证书原件、炉号、批号、生产日期。Allrawmaterialintotheplantshouldbewithmillcertificate,heatno.,batchno.,andproductiondate2、原材料化学元素含量、直径公差等应符合相关标准要求。Chemicalcompositionsand检测工具TESTEQUIPMENT直径DIAMETER化学元素CHEMICALCOMPOSITIONS表面SURFACE游标卡尺VERNIERCALIPER光谱仪SPECTRUMANALYZER目测BYVISUALφ宁波海信铁路器材有限公司NINGBOHAIXINRAILROADMATERIALCO.,LTD检验指导书INSPECTIONINSTRUCTIONS产品名称PRODUCTNAME螺母NUT材料MATERIAL第2张PAGE2共12张TOTAL12PAGES产品级别GRADE编号SERIALNO.版本VERSIONB0工序号PROCESSNO.2工序名称PROCESSNAME原材料退火RAWMATERIALANNEALING使用设备EQUIPMENT天然气退火炉ANNEALFURNACEWITHNATURALGAS备注REMARKSdiametertolerancesshouldconformtorelevantstandardrequirements.3、钢材表面不得有锈蚀、麻点、裂缝、折叠、拉痕等缺陷。Steelsurfacecan’thaverust,pitting,cracks,folds,pullmarksandotherdefects.4、钢材的外径用游标卡尺测量。External0-150LAD3000S编制EDITOR日期DATE审批RATIFIER日期DATE签字2010年12月10要求REQUIREMENTS1、进厂原材料须有质量保证书原件、炉号、批号、生产日期。Allrawmaterialintotheplantshouldbewithmillcertificate,heatno.,batchno.,andproductiondate2、原材料化学元素含量、直径公差等应符合相关标准要求。Chemicalcompositionsanddiametertolerancesshouldconformtorelevantstandardrequirements.3、钢材表面不得有锈蚀、麻点、裂缝、折叠、拉痕等缺陷。Steelsurfacecan’thaverust,pitting,cracks,folds,pullmarksandotherdefects.4、钢材的外径用游标卡尺测量。Externaldiametershouldbemeasuredbyverniercaliper.5、钢材化学元素含量用光谱仪。参考《质保书》Chemicalcompositionsshouldbecheckedbyspectrumanalyzerandreferredtomillcertificate.检测工具TESTEQUIPMENT直径DIAMETER化学元素CHEMICALCOMPOSITIONS表面SURFACE游标卡尺VERNIERCALIPER光谱仪SPECTRUMANALYZER目测BYVISUAL0-150LAD3000S编制EDITOR日期DATE审批RATIFIER日期DATE签字SIGNATURE2010年12月10φ6、外观采用目测。Surfaceischeckedby宁波海信铁路器材有限公司NINGBOHAIXINRAILROADMATERIALCO.,LTD检验指导书INSPECTIONINSTRUCTIONS产品名称PRODUCTNAME螺母NUT材料MATERIAL第3张PAGE3共12张TOTAL12PAGES产品级别GRADE编号SERIALNO.版本VERSIONB0工序号PROCESSNO.3工序名称PROCESSNAME酸洗、水洗、磷化ACIDCLEANING,WASHING,PHOSPHATING使用设备EQUIPMENT备注REMARKS酸洗使用浓度5%~8%的盐酸Acidcleaningbyhydrochloricacidwithconcentrationfrom5%to8%要求REQUIREMENTS1、酸洗后钢材呈灰色,用清水洗净,不得有残余酸液。Steelafterpicklingshouldbegray,washedbywaterandwithoutresidualacid.2、酸洗后表面不得有氧化皮、黑色条纹,酸液腐蚀检测工具TESTEQUIPMENT表面SURFACE盐酸浓度hydrochloricacidconcentration等。Steelsurfaceafterpicklingshouldnothaveoxideskins,blackstripesandacidcorrosion.3、酸洗时,材料不得产生氢脆Hydrogenembrittlementshouldnothappenduringpicklingprocess.4、酸液浓度要每...