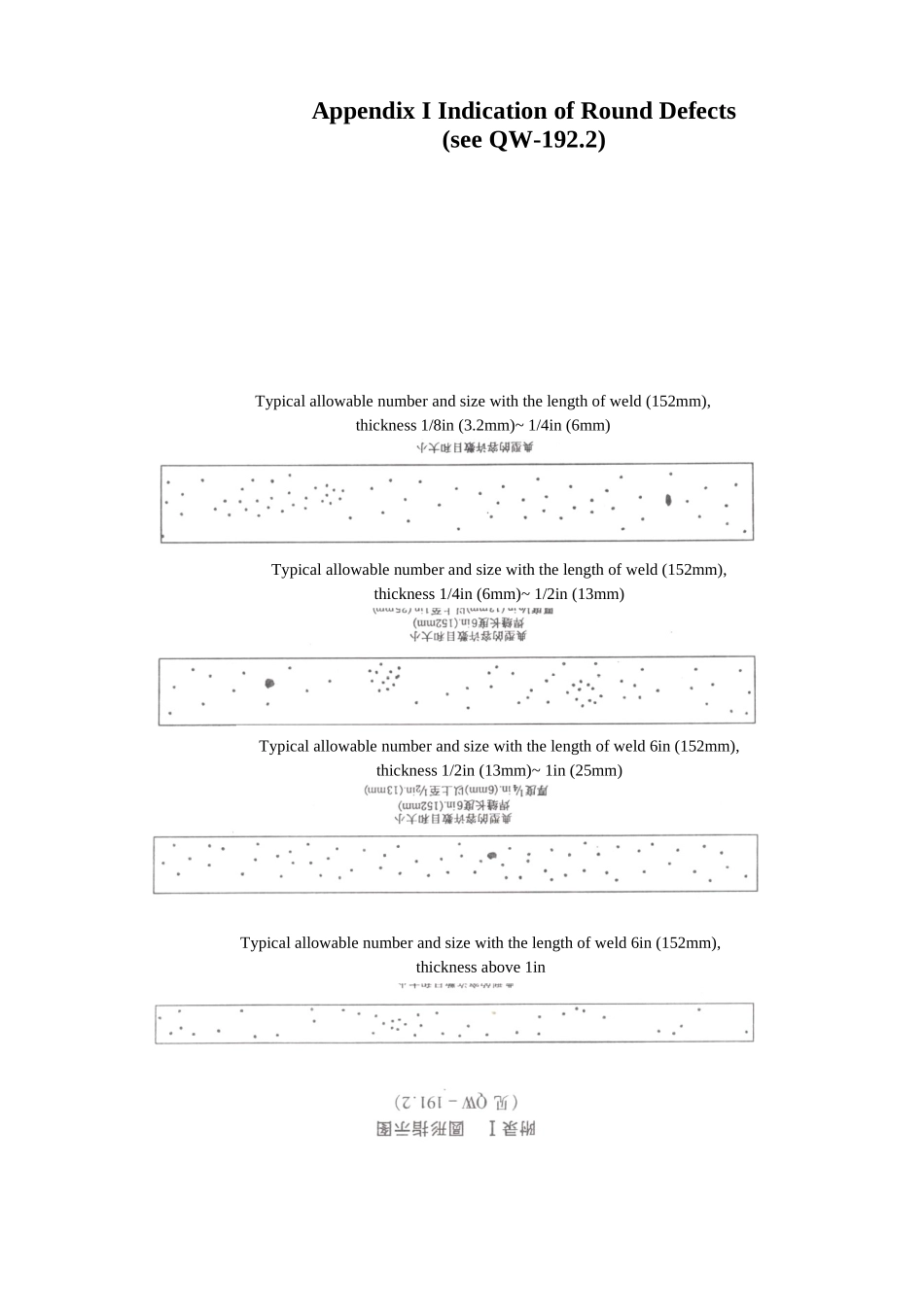

Welder,s Performance Qualification Test Procedure 焊工技能评定程序PREPARED BY编 制CHECKED BY审 核APPROVED BY批 准DATE日 期 0Rev.修订号Date日期Description更改说明Signature签字Checked By校核1. Scope1.1 The procedure is applied to the qualification of welder’s performance for P311 project of AA.1.2 This procedure is prepared according to the requirement in section 7.3 of API 650, as well as the Part IX of ASME.2. WeldersWelders participating performance qualification must be skilled workers with many years of experience on tank welding. 3. Contents of Qualification 3.1 Basis: ASME Ⅸ : Part QW, Chapter III; 3.2 Position: for Shielding Metal Arc Welding (SMAW), 2G (horizontal welding), 3G (vertical welding) and 4G (back welding) will be tested;3.3 For submerged arc welding (SAW), 2G (horizontal welding) welding position will be tested;3.4 For Tungsten argon arc welding and shielding metal arc welding of tube, 6G welding position (the tube is fixed in 45º.) will be tested;3.5 For FCAW, the 3G (vertical welding) welding position will be tested;3.6 The welder’s qualification shall be carried out after the welding process qualification is approved. 4. Approval CriteriaAfter the visual inspection on examination test piece is acceptable, is must be detected by radio graph. The test piece to be detected shall be 152mm (6in) at least. For tubes, the welding circumference shall be detected. Radio graphic detection shall meet the requirement specified in ASME IX QW-191.2.2, that is:4.1 Linear defect:4.1.1 Any type of cracks or poor penetration and lack of fusion;4.l.2 Extending length of slag inclusion is over:a.When the thickness ≤9.6mm (3/8in), with a length of 3.2mm (1/8in)b. When the thickness ≥9.6~57mm (3/8~2 1/4in),...