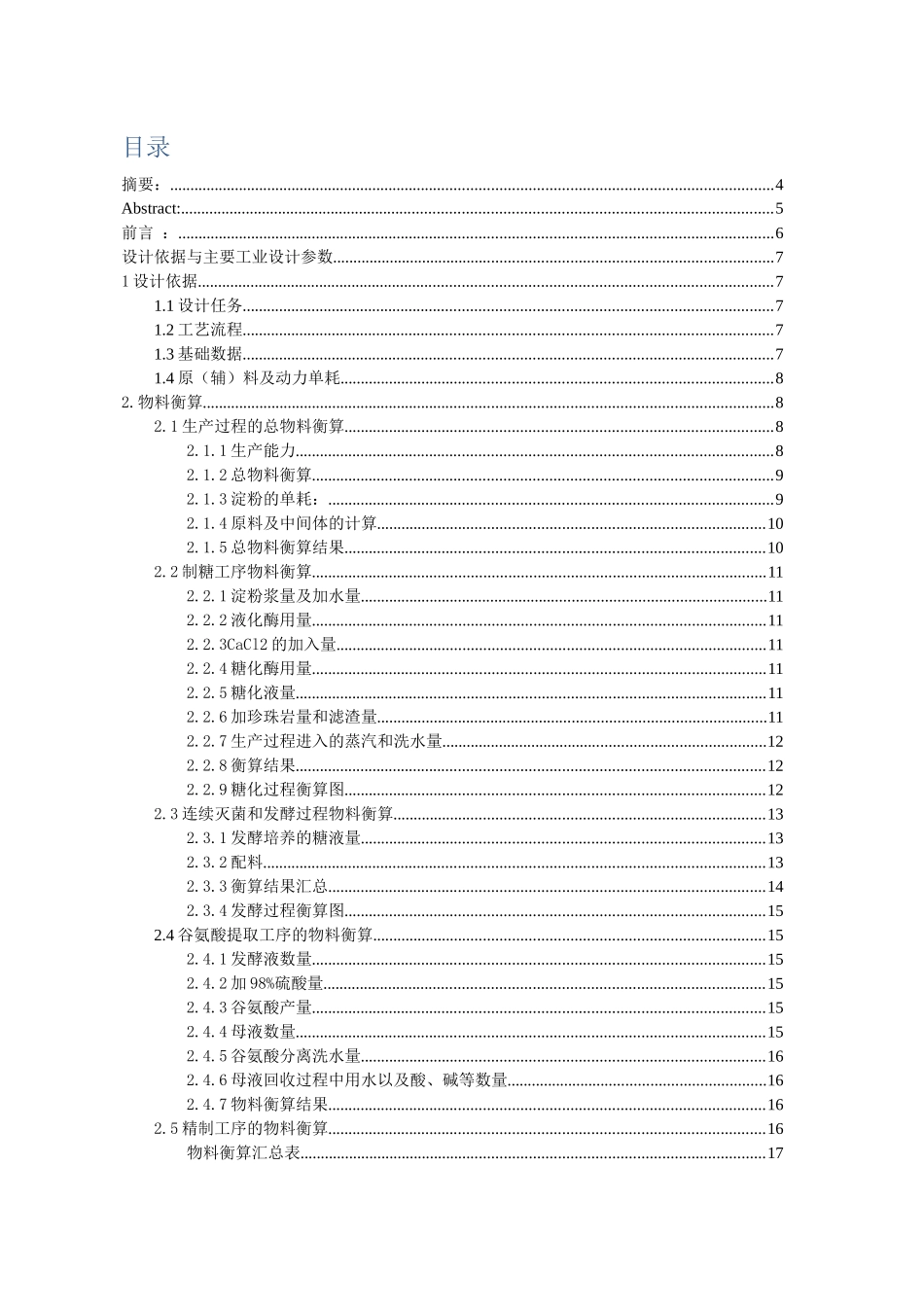

武汉工程大学化工与制药学院课程设计任务书年产9000吨味精工厂(以液氨为氮源)的生产工艺设计专业班级学生姓名学号日期年月日书面整理与设计:物料计算:绘图部分:目录摘要:...................................................................................................................................................4Abstract:................................................................................................................................................5前言:.................................................................................................................................................6设计依据与主要工业设计参数...........................................................................................................71设计依据............................................................................................................................................71.1设计任务.................................................................................................................................71.2工艺流程.................................................................................................................................71.3基础数据.................................................................................................................................71.4原(辅)料及动力单耗.........................................................................................................82.物料衡算...........................................................................................................................................82.1生产过程的总物料衡算........................................................................................................82.1.1生产能力....................................................................................................................82.1.2总物料衡算................................................................................................................92.1.3淀粉的单耗:............................................................................................................92.1.4原料及中间体的计算..............................................................................................102.1.5总物料衡算结果......................................................................................................102.2制糖工序物料衡算..............................................................................................................112.2.1淀粉浆量及加水量...................................................................................................112.2.2液化酶用量..............................................................................................................112.2.3CaCl2的加入量........................................................................................................112.2.4糖化酶用量..............................................................................................................112.2.5糖化液量..................................................................................................................112.2.6加珍珠岩量和滤渣量...............................................................................................112.2.7生产过程进入的蒸汽和洗水量................................................................