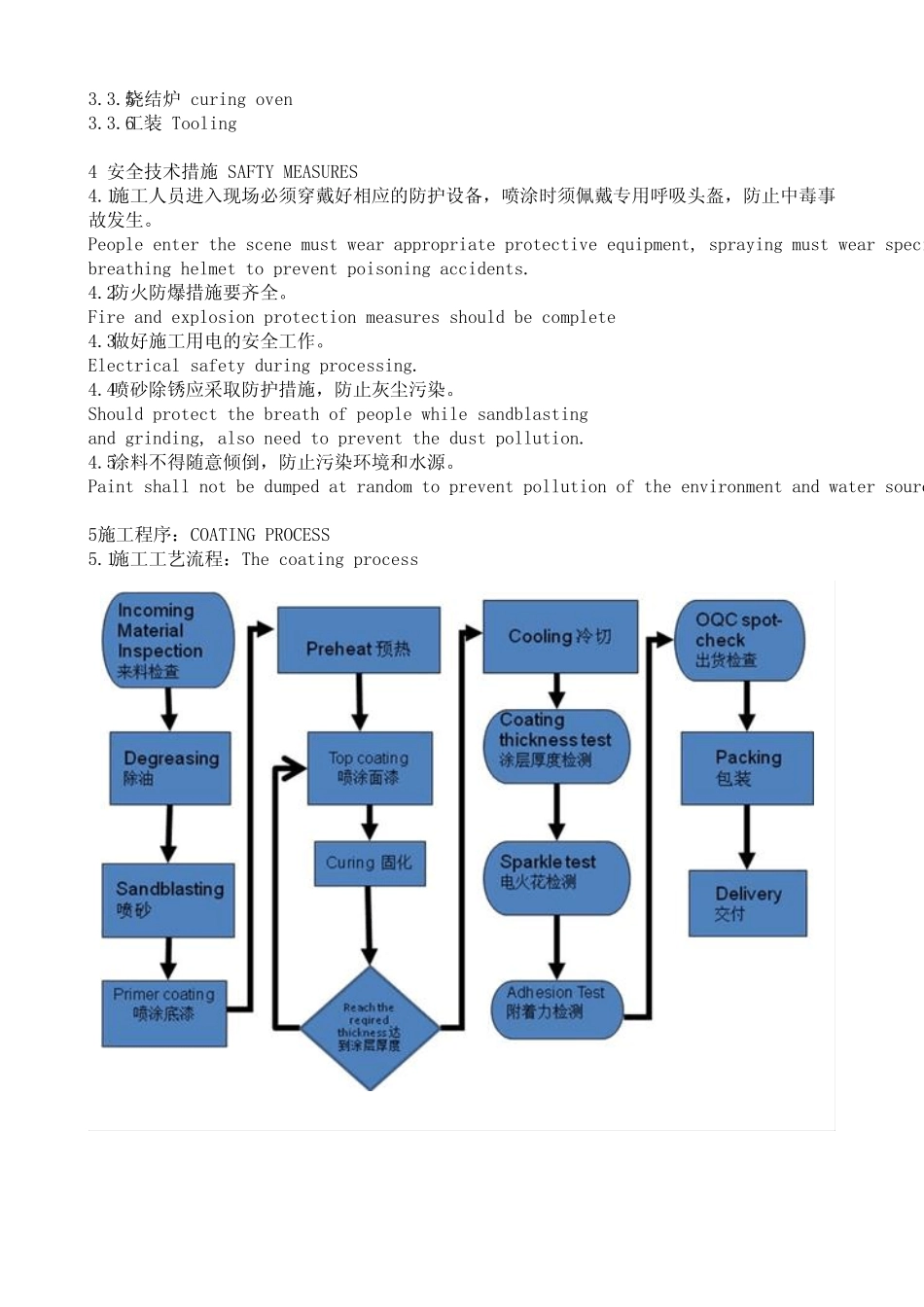

PFAAnticorrosionCoatingconstructionspecificationsPFA防腐涂层施工规范1范围Scope本规范规定PFA防腐涂层的施工和质量要求,适用于所有需PFA防腐涂层的设备制造.ThespecificationprovisionsconstructionandqualityrequirementsofPFAanticorrosivecoating,applicabletoallequipmentmanufactureneedtoPFAanticorrosivecoating2编制依据及规范Compilationbasisandspecification2.1产品图纸Drawingoftheproducts2.2《涂装前钢材表面锈蚀等级和除锈等级SurfacerustgradesandpreparationgradeofstellbeforeCoating》GB/T8923.12.3《工业设备、管道防腐蚀工程施工及验收规范Industrialequipment,pipelineanti-corrosioncoatingprocessandacceptancecriterion》HGJ2292.4《橡胶衬里化工设备设计规范Designcodeforchemicalequipmentwithrubberlining》HG/T206772.5《粘附胶带测试附着力的标准测试方法StandardTestMethodsforMeasuringAdhesionbyTapeTest》ASTMD33592.6《非铁素体金属基体表面非导电涂层干膜厚度无损检测的标准检测方法StandardTestMethodforNondestructiveMeasurementofDryFilmofNonconductiveCoatingsAppliedtoaNonferrousMetalBase》ASTM_D14003施工准备PREPARATION3.1技术准备Technicalpreparation3.1.1图纸会审工作已经完成,具有图纸会审记录。Drawingaudithasbeencompleted,witharelatedrecord.3.1.2根据设计文件要求,编制技术交底等技术文件。Preparationoftechnicaldisclosureandothertechnicaldocumentsaccordingtotherequirementsofdesignrequirement.3.1.3图纸的设计符合喷涂的要求。Thedesignofdrawingiscompliedwiththerequirementsofthecoating.A:所有的R角最好能达到R5,最低要求是R3;AlltheedgesisbettertoreachR5,MinR3;B:工件整体表明要求平滑过渡,不能有尖锐的角。不能有焊缝,焊渣,凹坑。Thesurfaceofcoatingareashouldbesmooth.Sharpcorner,weldingbeam,weldingslagandsteelpitarenotallowed.3.2材料准备Materialpreparation3.2.1准备好喷砂所需的砂料。Prepareallthesandneededforsandblasting.3.2.2准备好所需的涂料。涂料必须有相应的材质证明文件。Prepareallthecoatingmaterial,itshouldhaveCOA.3.3工具准备Facilitypreparation3.3.1喷砂机sandblastingmachie3.3.2打磨工具grindertools3.3.3静电喷枪staticpowderspraygun3.3.4吹灰枪sootlance3.3.5烧结炉curingoven3.3.6工装Tooling4安全技术措施SAFTYMEASURES4.1施工人员进入现场必须穿戴好相应的防护设备,喷涂时须佩戴专用呼吸头盔,防止中毒事故发生。Peopleenterthescenemustwearappropriateprotectiveequipment,sprayingmustwearspecialbreathinghelmettopreventpoisoningaccidents.4.2防火防爆措施要齐全。Fireandexplosionprotectionmeasuresshouldbecomplete4.3做好施工用电的安全工作。Electricalsafetyduringprocessing.4.4喷砂除锈应采取防护措施,防止灰尘污染。Shouldprotectthebreathofpeoplewhilesandblastingandgrinding,alsoneedtopreventthedustpollution.4.5涂料不得随意倾倒,防止污染环境和水源。Paintshallnotbedumpedatrandomtopreventpollutionoftheenvironmentandwatersources.5施工程序:COATINGPROCESS5.1施工工艺流程:Thecoatingprocess5.2进料检查Incominginspection::检查接收的罐体是否有碰伤,焊接处是否有焊缝,法兰等密封面是否有磕碰,各倒角是否按照图纸规范处理好。罐体内部是否清洗干净。如果有倒角最好能做到R5.Inspectingwhethertherearescratches,hurts,weldingseams.Whetherthechamferinaccordancewiththedrawingsandspecifications.Ifpossible,itisbettertoreachR5..Shouldtakeespeciallycaretotheflangeandsealingsurfaces.5.3喷砂除锈Sandblastingandgrinding采用20目到40目氧化铝喷砂。基体表面要求清洁,而具有一定的粗糙度,即达到GB50727《工业设备及管道防腐蚀工程施工质量验收规范》的Sa2.5级除锈标准,彻底除净表面的油质、氧化皮、锈蚀等一切杂物。并用干燥、洁净的压缩空气清除粉尘。表面无任何可见的残留物,呈现金属均一本色...