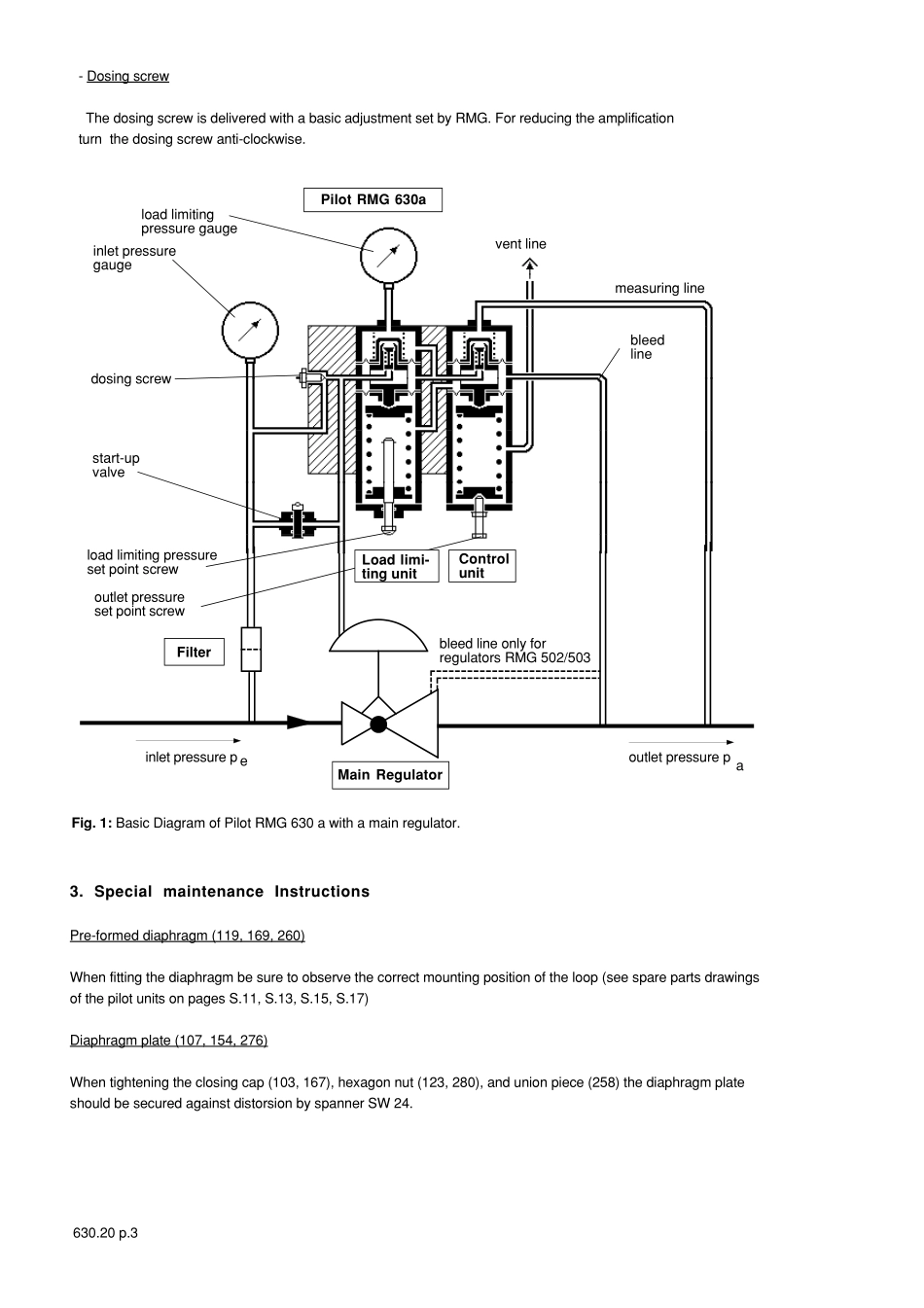

RMGREGEL+MESSTECHNIKGMBH...providingallcomponentsyouneedforreliabilityingassupplyBildeinsetzen(maximaleGröße)OperationandMaintenance630.20SparePartsEdition08/94Osterholzstraße45•D-34123Kassel•P.o.Box102967•D-34029KasselTelephone(0561)5007-0•Telefax(0561)5007-107•Telex0996261.GeneralRemarksOurleaflet630.00givesfullinformationwithtechnicaldata,differentversionsanddimensionsofthepilotRMG630a.Ourbrochure"GeneralOperatingInstructionsforGasPressureRegulatorsandSafetyDevices"willbeusefultofitthepilotintotheline,putitintoserviceandfindfaultsthatmightdisturbtheoperation.Theconstruction,set-up,supervisionandmaintenanceofgaspressureregulatingstationsaresubjecttospecialtechnicalruleswhichshouldbestrictlyobserved,inparticularthosegivenbytheDVGWWorksheetsG490,G491,andG495.ThefrequencyofperiodicalmaintenancetobeforeseenforthepilotRMG630ashouldbedeterminedaccordingtotheprevailingserviceconditionsandthetypeandcompositionofthegaseousmedium.We,therefore,abstainfromimposinganyfixedintervalsandwouldratherreferyoutotherecommendationsgivenbytheDVGWWorksheetG495.Formaintenanceallpartsaretobecleanedandsubjectedtoathoroughvisualinspection.Avisualinspectionshouldnotbeomittedwhenthecourseofoperationorperformancetestshaveshownlackofregulatingaccuracy.Particularcareshouldbegiventothecheckingofsealingsanddiaphragms,aswellasofallcarryingandmovableparts.Damagedpartsshouldbereplacedbynewones.Theitemnumbersreferredtointhemaintenanceinstructionsareidenticalwiththoseofsparepartsdrawingsandsparepartslists.Werecommendtokeepallpartsthatarespeciallymarkedinthesparepartslistsinstockforpromptmaintenanceavailability.630.20p.22.SpecialOperatingInstructions2.1Start-upvalveDependingonsize,thegaspressureregulatorsRMG402/502/503areprovidedwithastart-upvalvetofacilitateaquickpressurecompensationtobeeffectedattheregulationsdiaphragmuponpressurization.Thefollowingregulatorswilbeprovidedwithastart-upvalve:•Beforepressurizingopenthestart-upvalve.•Afterpressurizingclosethestart-upvalve.2.2AdjustingtheloadlimitingpressureRMG402RMG502/503fromDN50withpilotRMG630a/640fromDN80withpilotRMG620/630a/640DN80/150,100/200RMG502,503approx10-15barRMG402approx5-10barTheleveloftheadjustedloadlimitingpressureexertsagreatinfluenceontheregulatingaccuracyofthepilot.Intheordertoreachahighregulatingaccuracycombinedwithalowclosingpressuretheloadlimitingpressureshouldberaisedtosuchalevelaswouldnotprejudicetheoperationalstabilityofthegaspressureregulatingstation.Werecommendtosettheloadlimitingpressureasfollows:Loadlimitingsetpointlevelabovetheoutletpressurewithregulators3.SpecialmaintenanceInstructionsPre-formeddiaphragm(119,169,260)Whenfittingthediaphragmbesuretoobservethecorrectmountingpositionoftheloop(seesparepartsdrawingsofthepilotunitsonpagesS.11,S.13,S.15,S.17)Diaphragmplate(107,154,276)Whentighteningtheclosingcap(103,167),hexagonnut(123,280),andunionpiece(258)thediaphragmplateshouldbesecuredagainstdistorsionbyspannerSW24.loadlimitingpressuregaugemeasuringlinestart-upvalveloadlimitingpressuresetpointscrewoutletpressuresetpointscrewventlineinletpressuregaugedosingscrewPilotRMG630ableedlineMainRegulatorinletpressurepoutletpressurepeaFilterFig.1:BasicDiagramofPilotRMG630awithamainregulator.630.20p.3-DosingscrewThedosingscrewisdeliveredwithabasicadjustmentsetbyRMG.Forreducingtheamplificationturnthedosingscrewanti-clockwise.bleedlineon...