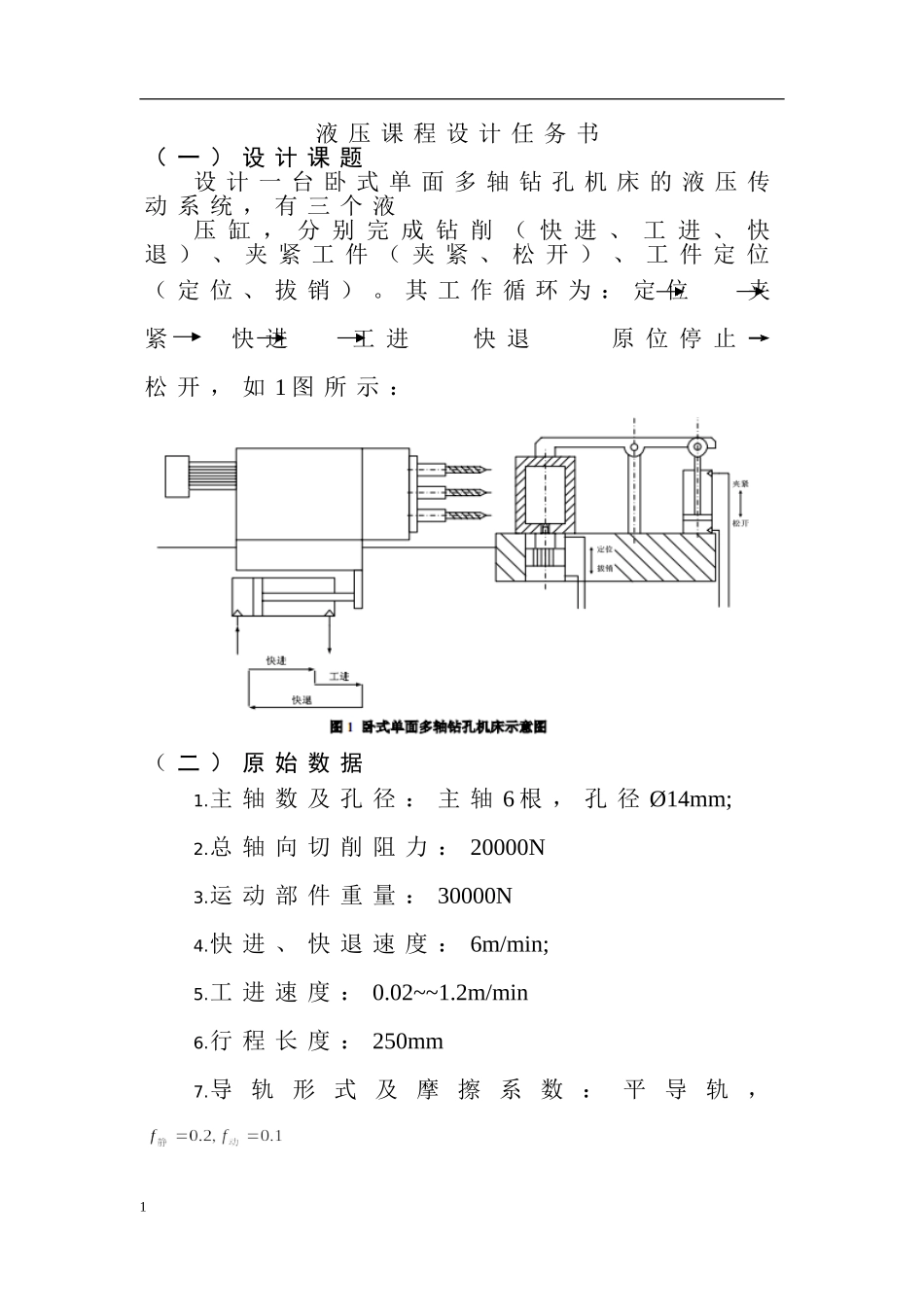

液压课程设计任务书(一)设计课题设计一台卧式单面多轴钻孔机床的液压传动系统,有三个液压缸,分别完成钻削(快进、工进、快退)、夹紧工件(夹紧、松开)、工件定位(定位、拔销)。其工作循环为:定位夹紧快进工进快退原位停止→松开,如1图所示:(二)原始数据1.主轴数及孔径:主轴6根,孔径Ø14mm;2.总轴向切削阻力:20000N3.运动部件重量:30000N4.快进、快退速度:6m/min;5.工进速度:0.02~~1.2m/min6.行程长度:250mm7.导轨形式及摩擦系数:平导轨,18.加速、减速时间:大于0.2秒9.夹紧力:4000N10.夹紧时间:1~2秒11.夹紧液压缸行程长度:16mm(三)系统设计要求1.夹紧后在工作中如突然停电时,要保证安全可靠,当主油路压力瞬时下降时,夹紧缸保持夹紧力;2.快进转工进时要平稳可靠3.钻削是速度平稳,不受外载干扰,孔钻透时不前冲(四)最后提交内容(电子稿和打印稿各一份)1.设计说明书各一份2.系统原理图一份,含电磁铁动作顺序表,主要元件明细表3.液压阀块二维CAD零件图(A3,比例1:1或者1:2)4.液压阀块三位实体图5.可选部分,包含液压阀块,阀块安装件的三维实体图2目录液压课程设计任务书···················································································I1工况分析································································································11.1动作要求分析··················································································11.2设计要求及工况分析··············································································11.3负载图和速度图的绘制·········································································12液压系统方案设计····················································································22.1确定液压泵类型及调速方式·····································································22.2选用执行元件······················································································22.3快速运动回路和速度换接回路··································································22.4换向回路的选III择···················································································22.5定位夹紧回路的选择·············································································22.6动作换接的控制方式选择·······································································22.7液压基本回路的组成·············································································33液压系统的参数计算································...