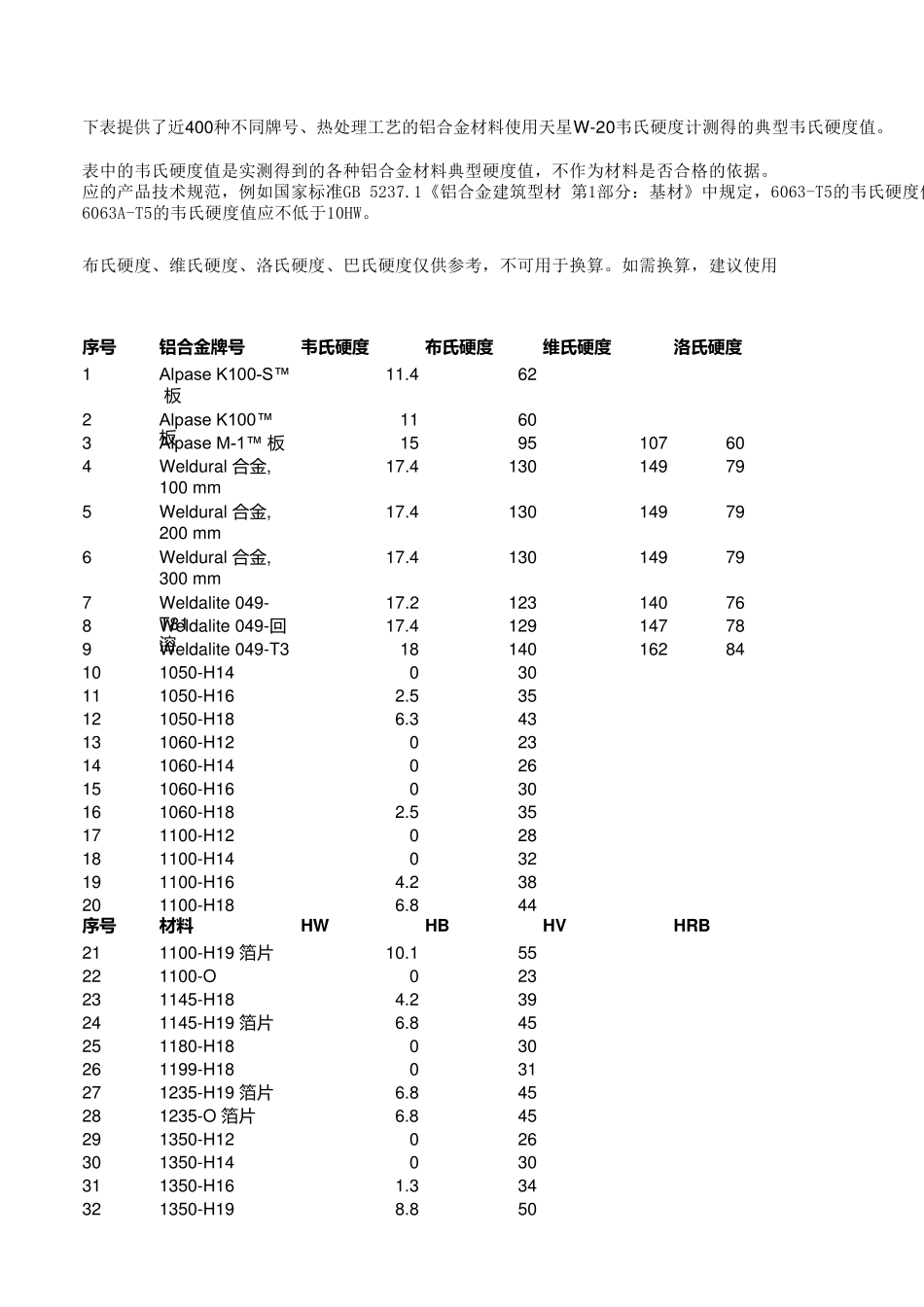

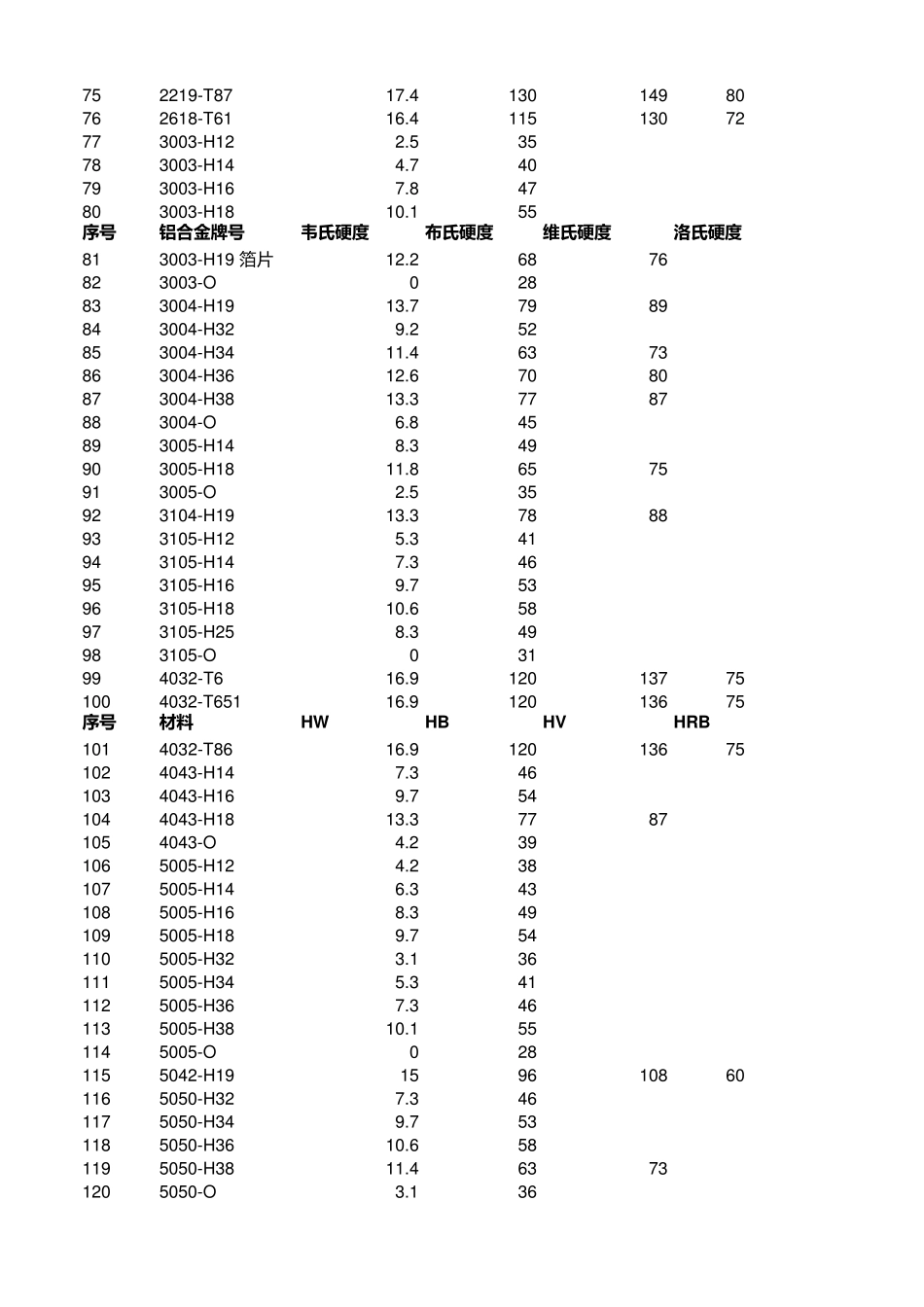

序 号铝合金牌号韦氏硬度布氏硬度维氏硬度洛氏硬度1Alpase K100-S™ 板11.4622Alpase K100™ 板11603Alpase M-1™ 板1595107604Weldu ral 合金, 100 mm17.4130149795Weldu ral 合金, 200 mm17.4130149796Weldu ral 合金, 300 mm17.4130149797Weldalite 049-T8117.2123140768Weldalite 049-回溶17.4129147789Weldalite 049-T31814016284101050-H14030111050-H162.535121050-H186.343131060-H12023141060-H14026151060-H16030161060-H182.535171100-H12028181100-H14032191100-H164.238201100-H186.844序 号材料HWHBHVHRB211100-H19 箔片10.155221100-O023231145-H184.239241145-H19 箔片6.845251180-H18030261199-H18031271235-H19 箔片6.845281235-O 箔片6.845291350-H12026301350-H14030311350-H161.334321350-H198.850下表提供了近400种不同牌号、热处理工艺的铝合金材料使用天星W-20韦氏硬度计测得的典型韦氏硬度值。表中的韦氏硬度值是实测得到的各种铝合金材料典型硬度值,不作为材料是否合格的依据。应的产品技术规范,例如国家标准GB 5237.1《铝合金建筑型材 第1部分:基材》中规定,6063-T5的韦氏硬度值应6063A-T5的韦氏硬度值应不低于10HW。布氏硬度、维氏硬度、洛氏硬度、巴氏硬度仅供参考,不可用于换算。如需换算,建议使用331350-O023342011-T3159510760352011-T3159510760362011-T413.7809049372011-T615.39710961382011-T815.310011263392011-T815.310011263402014-O6.845序 号铝合金牌号韦氏硬度布氏硬度维氏硬度洛氏硬度412014-T4; 2014-T45115.910511867422014-T6; 2014-T65117.813515582432017-O6.845442017-T4; 2017-T45115.910511866452018-T6116.912013775462024-O7.847472024-T316.912013775482024-T36117.413014980492024-T4; 2024-T35116.912013775502024-T617.212514278512024-T8117.412814679522024-T85117.412814679532024-T8617.813515582542025-T616.211012469552036-T415951076056204816.912213976572090-O10.657582090-T314.3869753592090-T841814016284602091-T8x16.411513071序 号材料HWHBHVHRB612091-T8x, 0.1 冷变形16.912013775622117-T412.67081632124-T35116.912013775642124-T85117.412814679652218-T6116.411512671662218-T7115.910511866672218-T72159510760682219-O7.346692219-T3115.310011363702219-T35115.310011363712219-T3716.711713373722219-T6216.41151...