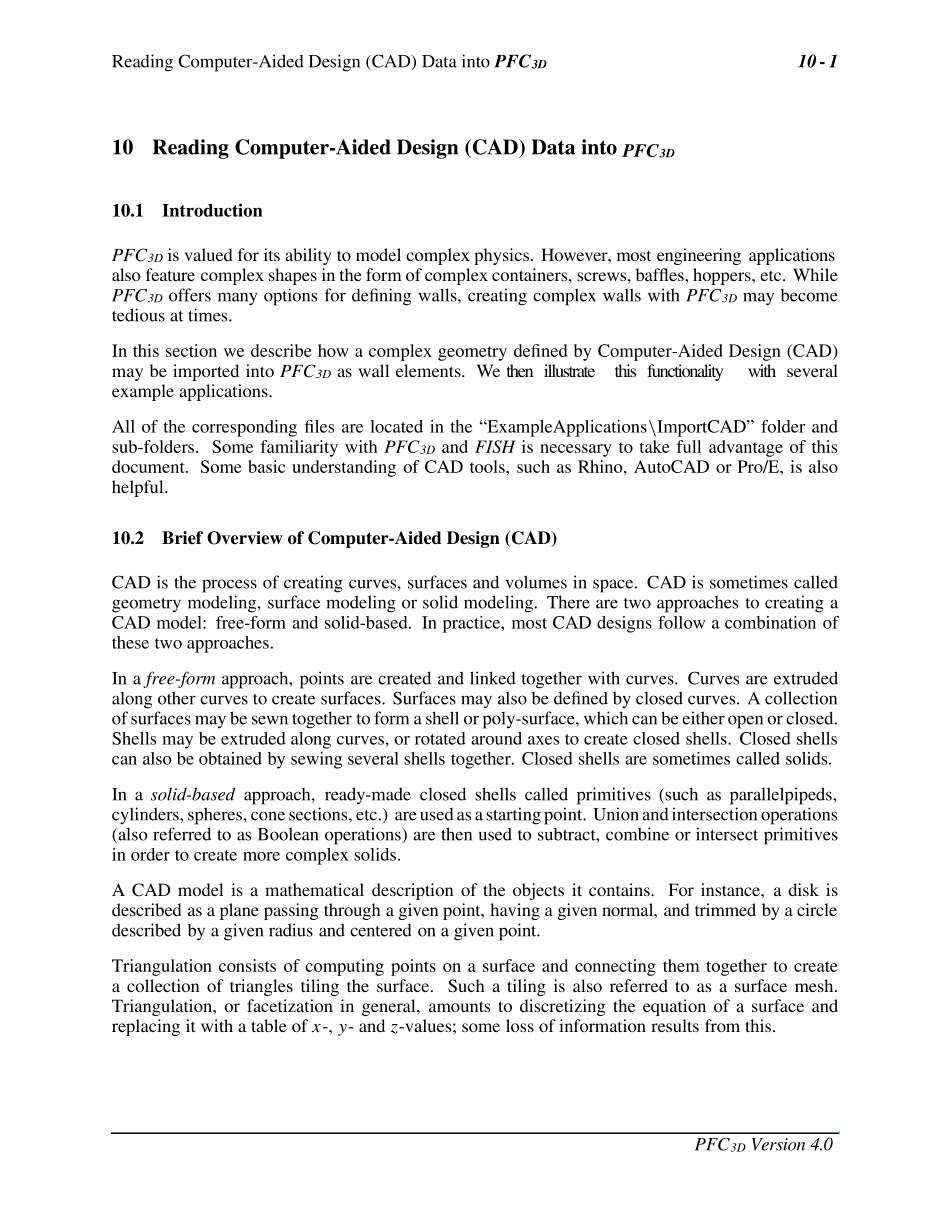

Reading Computer-Aided Design (CAD) Data into PFC3D10 - 110Reading Computer-Aided Design (CAD) Data into PFC3D10.1IntroductionPFC3D is valued for its ability to model complex physics. However, most engineering applicationsalso feature complex shapes in the form of complex containers, screws, baffles, hoppers, etc. WhilePFC3D offers many options for defining walls, creating complex walls with PFC3D may becometedious at times.In this section we describe how a complex geometry defined by Computer-Aided Design (CAD)may be imported into PFC3D as wall elements. We then illustratethis functionalitywith severalexample applications.All of the corresponding files are located in the “ExampleApplications\ImportCAD” folder andsub-folders. Some familiarity with PFC3D and FISH is necessary to take full advantage of thisdocument. Some basic understanding of CAD tools, such as Rhino, AutoCAD or Pro/E, is alsohelpful.10.2Brief Overview of Computer-Aided Design (CAD)CAD is the process of creating curves, surfaces and volumes in space. CAD is sometimes calledgeometry modeling, surface modeling or solid modeling. There are two approaches to creating aCAD model: free-form and solid-based. In practice, most CAD designs follow a combination ofthese two approaches.In a free-form approach, points are created and linked together with curves. Curves are extrudedalong other curves to create surfaces. Surfaces may also be defined by closed curves. A collectionof surfaces may be sewn together to form a shell or poly-surface, which can be either open or closed.Shells may be extruded along curves, or rotated around axes to create closed shells. Closed shellscan also be obtained by sewing several shells together. Closed shells are sometimes called solids...