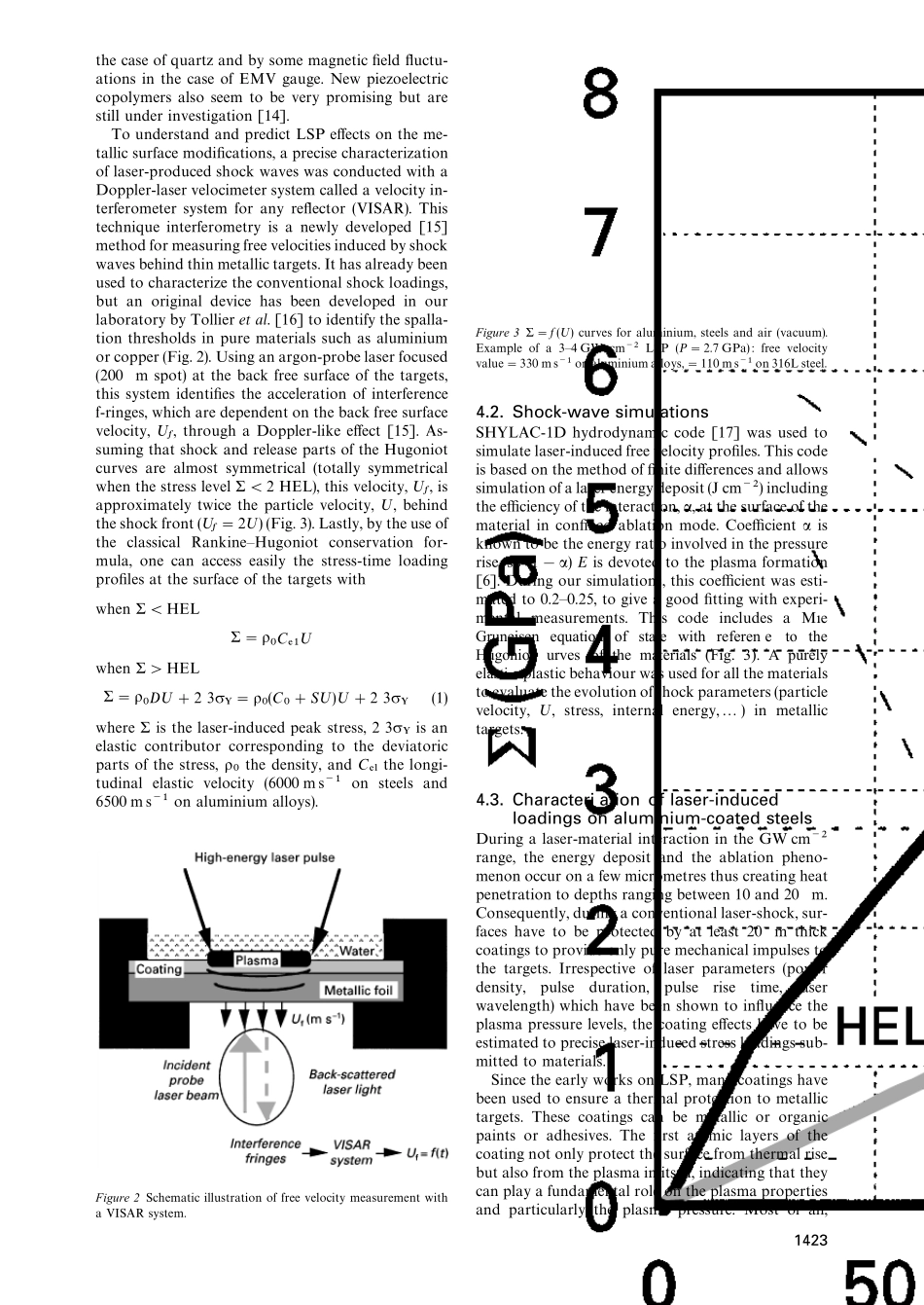

JOURNAL OF MATERIALS SCIENCE 33 (1998) 1421 — 1429Laser-shock processing of aluminium-coated55C1 steel in water-confinement regime,characterization and application to high-cyclefatigue behaviourP. PEYRE, L. BERTHE, X. SCHERPEREEL, R. FABBROCLFA-LALP,Unite& mixteETCA-CNRS,94114Arcueil,France55C1steelwasirradiatedwitha high-powerneodymium—glasslaserwithapplicationtoinduceplasticshockwaveswithintargets,throughtheexpansionof a laser-inducedsurfaceplasma.Laser-shockprocessingexperimentswereconducedintheplasma-confi nedregimewithwaterto increasethelaser-inducedpeakstresses.Physical,mechanicalandprocessingsaspectswerereviewed,suchas thecharacterizationof stresswavesin coatedsteelswitha VISARvelocimetersystem,andthemechanicalchangesinducedin 55Clintermsofcompressiveresidualstressesorwork-hardeninglevels.Withtheuseofconvenientprotectivecoatings,some7—8 GPapeakstresslevelscouldbeachievedwhichauthorizedthegenerationof highcompressiveresidualstresslevels(nearly80%of thecompressiveyieldstrength),butpreservedthesurfaceintegrityfromdetrimentalroughening.Surfacemodifi cationsperformedunderdifferentshockconditionswereshowntodisplaysome30%increaseon thebendingfatiguelimitsof 55C1at R:0.1.© 1998Chapman& Hall1. IntroductionIn the fi eldof surfacetreatments,lasersourcesareusuallyusedas fl exibleheatsourcesin investigationof solid-phasetransformations[1],surfaceremelting(crankshaftapplications)or surfacealloying[2].Amongthewidevarietyof surfacetreatmentsinvesti-gatedfor improvingpropertiesof materials,laser-shockprocessing(LSP)wasdevelopedabout25 yearsagoin the USA[3,4] withparticularapplicationtoenhancefatiguepropertiesof fastenedjointsforaero-nauticalapplications.Manyindustrialmaterialswereinvestigatedat thistime,suchas aluminiumor tita-niumalloys,orstainlesssteels,butbecauseofthelackof reliablepulsed-lasersources(highcadency—highpowerdensity)anddespitethesatisfactorymechanicalimprovementsdisplayedin aluminiu...