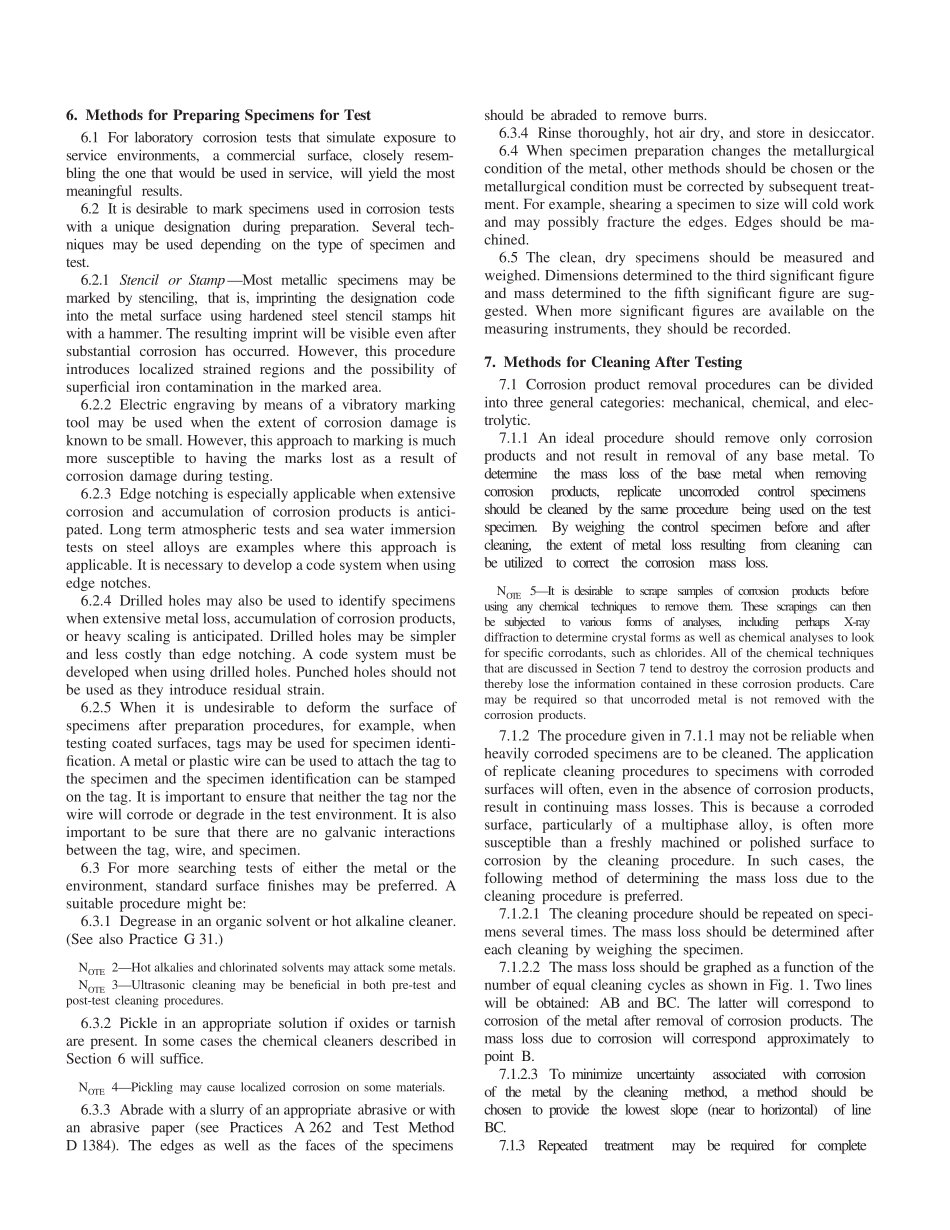

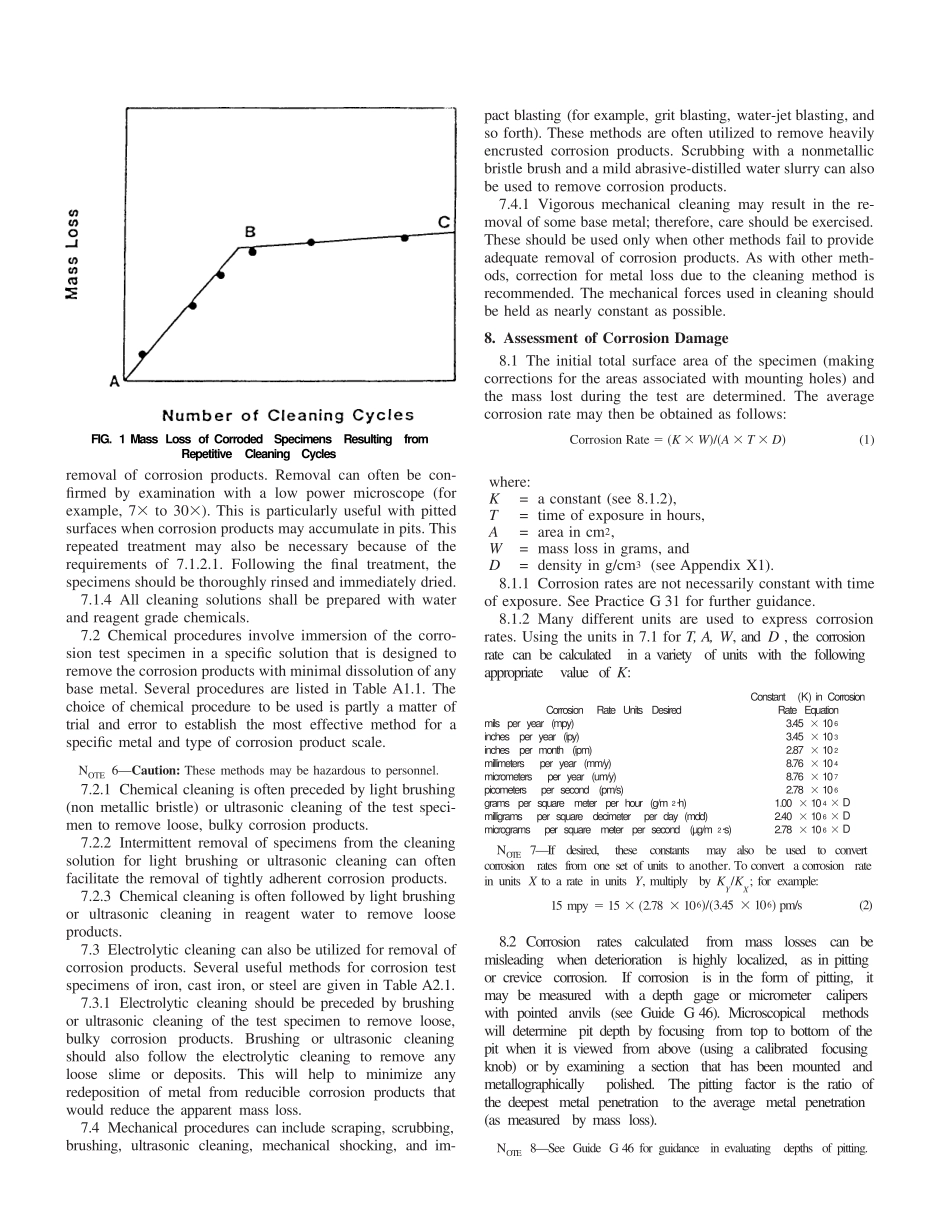

6. Methods for Preparing Specimens for Test6.1 For laboratory corrosion tests that simulate exposure toservice environments,a commercial surface, closely resem-bling the one that would be used in service, will yield the mostmeaningful results.6.2 It is desirable to mark specimens used in corrosion testswith a unique designation during preparation. Several tech-niques may be used depending on the type of specimen andtest.6.2.1 Stencil or Stamp—Most metallic specimens may bemarked by stenciling, that is, imprinting the designation codeinto the metal surface using hardened steel stencil stamps hitwith a hammer. The resulting imprint will be visible even aftersubstantial corrosion has occurred. However, this procedureintroduces localized strained regions and the possibility ofsuperficial iron contamination in the marked area.6.2.2 Electric engraving by means of a vibratory markingtool may be used when the extent of corrosion damage isknown to be small. However, this approach to marking is muchmore susceptible to having the marks lost as a result ofcorrosion damage during testing.6.2.3 Edge notching is especially applicable when extensivecorrosion and accumulation of corrosion products is antici-pated. Long term atmospheric tests and sea water immersiontests on steel alloys are examples where this approach isapplicable. It is necessary to develop a code system when usingedge notches.6.2.4 Drilled holes may also be used to identify specimenswhen extensive metal loss, accumulation of corrosion products,or heavy scaling is anticipated. Drilled holes may be simplerand less costly than edge notching. A code system must bedeveloped when using drilled holes. Punched holes should notbe used as they introduce residual strain.6.2.5 When...