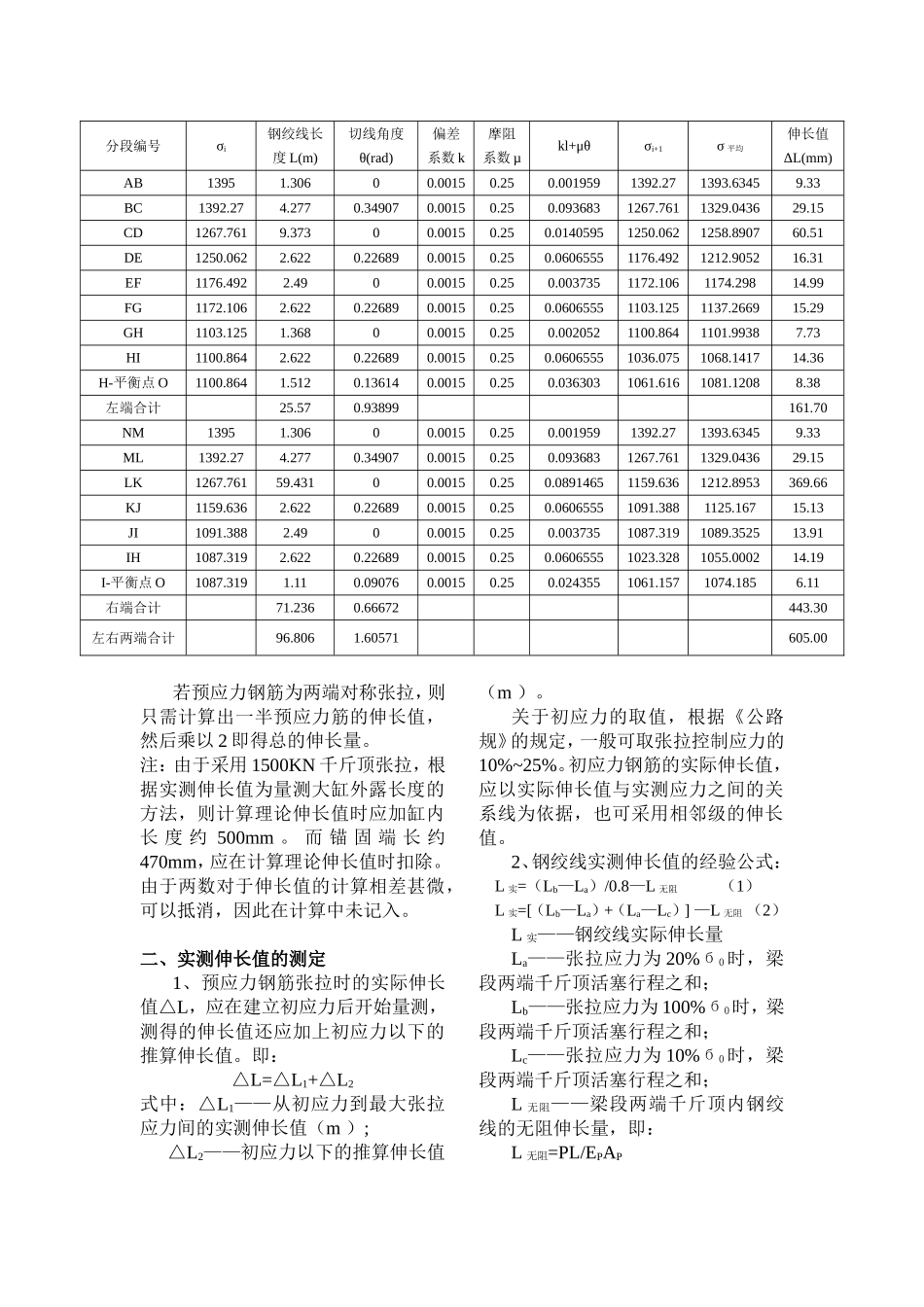

后张法预应力张拉伸长量计算与测定分析一、理论伸长量计算1、理论公式:(1)根据《公路桥涵施工技术规范》(JTJ041—2000),钢绞线理论伸长量计算公式如下:①②式中:PP——预应力筋的平均张拉力(N),直线筋取张拉端的拉力,曲线筋计算方法见②式;——预应力筋的长度;AP——预应力筋的截面面积(mm2);EP——预应力筋的弹性模量(N/mm2);P——预应力筋张拉端的张拉力(N);——从张拉端至计算截面的孔道长度(m);——从张拉端至计算截面的孔道部分切线的夹角之和(rad);——孔道每米局部偏差对摩擦的影响系数;——预应力筋与孔道壁的摩擦系数。(2)计算理论伸长值,要先确定预应力筋的工作长度和线型段落的划分。后张法钢绞线型既有直线又有曲线,由于不同线型区间的平均应力会有很大差异,因此需要分段计算伸长值,然后累加。于是上式中:Pp值不是定值,而是克服了从张拉端至第i—1段的摩阻力后的剩余有效拉力值,所以表示成“Ppi”更为合适;(3)计算时也可采取应力计算方法,各点应力公式如下:各点平均应力公式为:各点伸长值计算公式为:2、根据规范中理论伸长值的公式,举例说明计算方法:某后张预应力连续箱梁,其中4*25米联内既有单端张拉,也有两端张拉。箱梁中预应力钢束采用高强度低松弛钢绞线(Φ15.24),极限抗拉强度fp=1860Mpa,锚下控制应力б0=0.75fp=1395Mpa。K取0.0015/m,µ=0.25。(1)单端张拉预应力筋理论伸长值计算:预应力筋分布图(1)伸长值计算如下表:分段编号σi钢绞线长度L(m)切线角度θ(rad)偏差系数k摩阻系数µkl+μθσi+1σ平均伸长值ΔL(mm)AB13951.02100.00150.250.00153151392.8651393.9327.30BC1392.8654.3230.366520.00150.250.09811451262.6951326.71629.41CD1262.6958.05700.00150.250.01208551247.5271255.09651.86DE1247.5272.9020.2443460.00150.250.06543951168.5031207.58417.97EF1168.5031.7200.00150.250.002581165.4921166.99710.29FG1165.4922.9020.2443460.00150.250.06543951091.6651128.17616.79GH1091.6652.94200.00150.250.0044131086.8581089.2616.43HI1086.8583.1810.26180.00150.250.07022151013.1551049.57517.12IJ1013.1552.20700.00150.250.00331051009.8071011.4811.45伸长值178.63(2)两端非对称张拉计算:预应力筋分布图(2)伸长值计算如下表:分段编号σi钢绞线长度L(m)切线角度θ(rad)偏差系数k摩阻系数µkl+μθσi+1σ平均伸长值ΔL(mm)AB13951.30600.00150.250.0019591392.271393.63459.33BC1392.274.2770.349070.00150.250.0936831267.7611329.043629.15CD1267.7619.37300.00150.250.01405951250.0621258.890760.51DE1250.0622.6220.226890.00150.250.06065551176.4921212.905216.31EF1176.4922.4900.00150.250.0037351172.1061174.29814.99FG1172.1062.6220.226890.00150.250.06065551103.1251137.266915.29GH1103.1251.36800.00150.250.0020521100.8641101.99387.73HI1100.8642.6220.226890.00150.250.06065551036.0751068.141714.36H-平衡点O1100.8641.5120.136140.00150.250.0363031061.6161081.12088.38左端合计25.570.93899161.70NM13951.30600.00150.250.0019591392.271393.63459.33ML1392.274.2770.349070.00150.250.0936831267.7611329.043629.15LK1267.76159.43100.00150.250.08914651159.6361212.8953369.66KJ1159.6362.6220.226890.00150.250.06065551091.3881125.16715.13JI1091.3882.4900.00150.250.0037351087.3191089.352513.91IH1087.3192.6220.226890.00150.250.06065551023.3281055.000214.19I-平衡点O1087.3191.110.090760.00150.250.0243551061.1571074.1856.11右端合计71.2360.66672443.30左右两端合计96.8061.60571605.00若预应力钢筋为两端对称张拉,则只需计算出一半预应力筋的伸长值,然后乘以2即得总的伸长量。注:由于采用1500KN千斤顶张拉,根据实测伸长值为量测大缸外露长度的方法,则计算理论伸长值时应加缸内长度约500mm。而锚固端长约470mm,应在计算理论伸长值时扣除。由于两数对于伸长值的计算相差甚微,可以抵消,因此在计算中未记入。二、实测伸长...