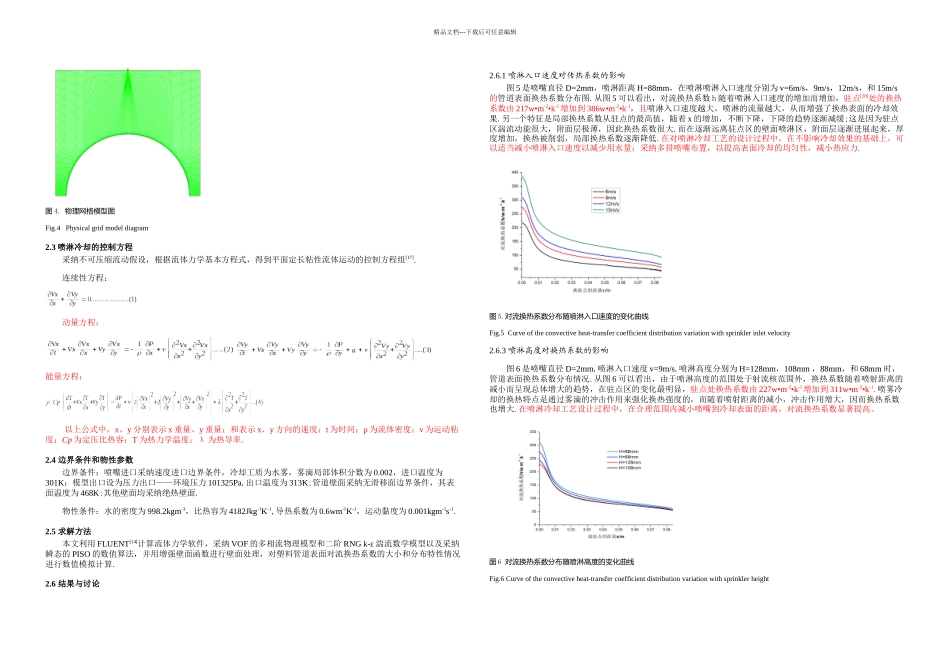

精品文档---下载后可任意编辑摘要:冷却系统是塑料挤出管道生产工艺中的关键设备,其冷却的均匀性和效率直接影响管道产品的质量及生产速度.本文首先基于ANSYS 对喷淋冷却瞬态传热进行模拟,结果表明:对流换热系数小于 180w•m-2•k-1时,冷却至目标温度(47℃)所需的时间随换热系数的变化明显;换热系数大于 180w•m-2•k-1时,冷却至目标温度所需的时间随换热系数的变化不大.然后基于 FLUENT 软件对喷淋喷嘴进行模拟,讨论了喷淋入口速度、喷嘴高度对喷淋换热系数的影响,结果表明:随着喷淋入口速度的增加(6~15m/s 的范围内),总体对流换热系数增大,驻点处的换热系数由 217 w•m-2•k-1增加到 386w•m-2•k-1;随喷淋高度的减小(68~128mm 范围内),壁面换热系数呈增加趋势,驻点处换热系数由 227 w•m-2•k-1增加到 311w•m-2•k-1.基于以上讨论,为真空定径喷淋冷却水槽的整体优化提出合理建议.关键词:挤出塑料管;喷淋冷却;喷嘴;瞬态;对流;换热;数值模拟;整体优化Numerical Simulation of Spray Cooling for Extruded Plastic PipeAbstract:Cooling system is essential in the production process of the extruded plastic pipe,which determine the length of plastic pipe production line and product quality. Firstly, this article imitated the transient heat transfer of the spray cooing based on ANSYS.The result shows: if the convective heat transfer coefficient is less than 180 W•m-2•k-1, time to be cooing to 47 changes obviously with the convective heat transfer coefficient; However, it not changes much if the ℃convective heat transfer coefficient is over 180 W•m-2•k-1.Then we imitate the spray nozzle based on “FLUENT software”, from the aspect of entrance velocity, the spray heightwhich may have effect on distribution of the convective heat transfer coefficient.We found that if other parameter constant, total convective heat transfer coefficient increase with the faster of entrance velocity (within 6~15 m/s),heat transfercoefficient of stagnation point increases fr...