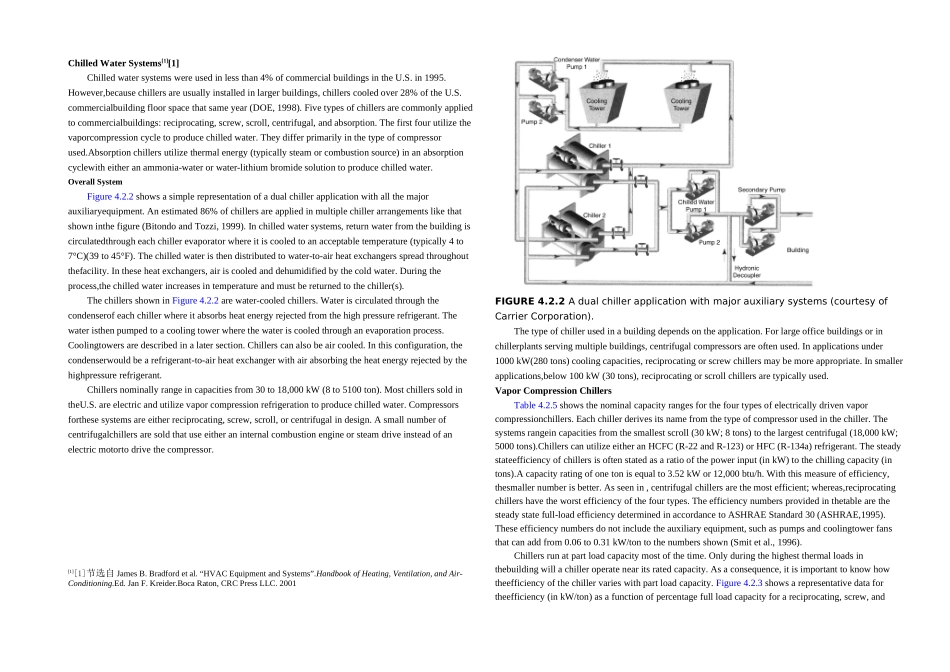

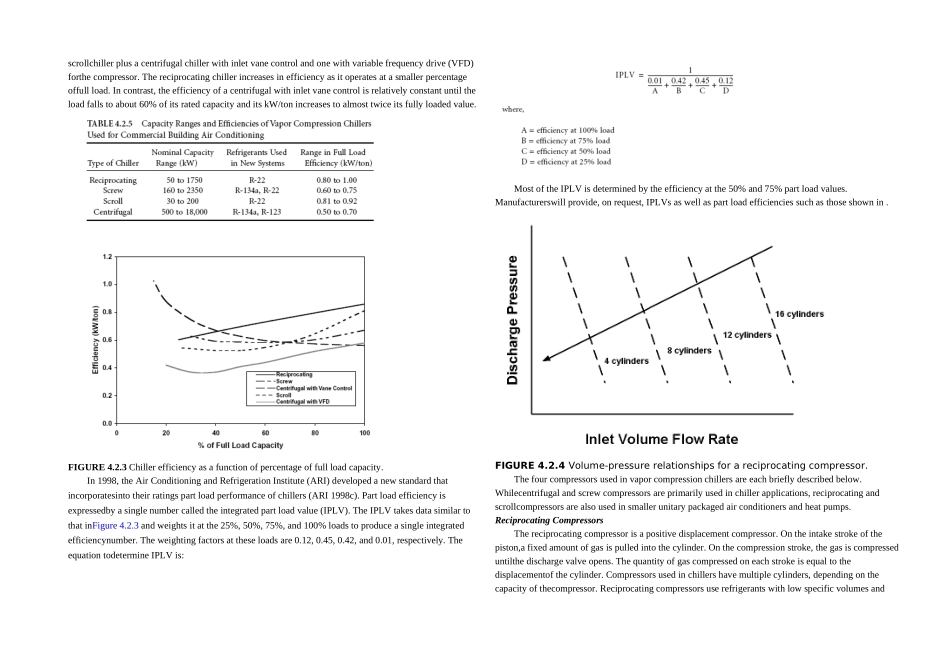

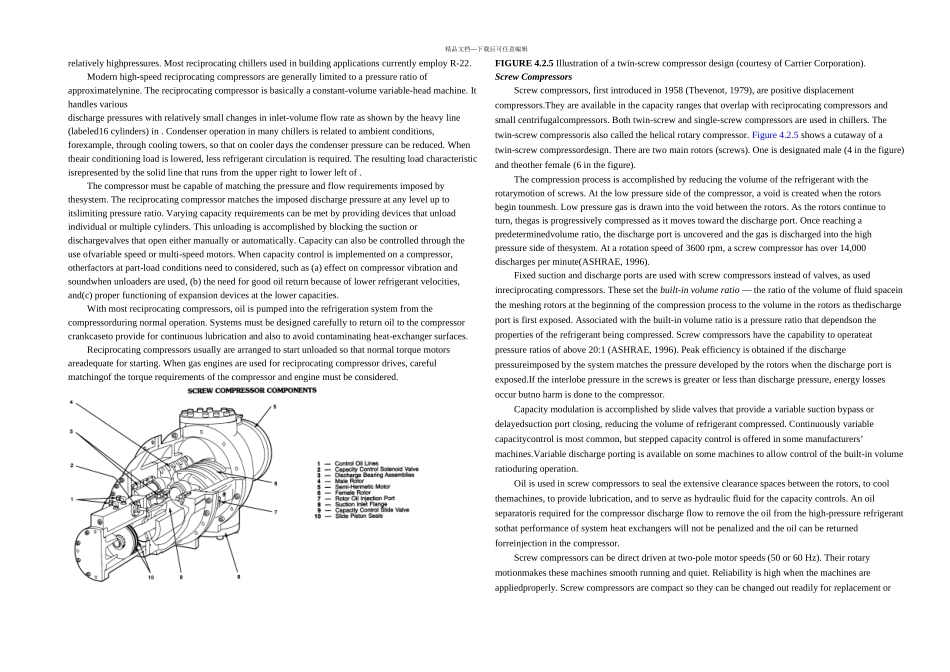

Chilled Water Systems[1][1]Chilled water systems were used in less than 4% of commercial buildings in the U.S. in 1995. However,because chillers are usually installed in larger buildings, chillers cooled over 28% of the U.S. commercialbuilding floor space that same year (DOE, 1998). Five types of chillers are commonly applied to commercialbuildings: reciprocating, screw, scroll, centrifugal, and absorption. The first four utilize the vaporcompression cycle to produce chilled water. They differ primarily in the type of compressor used.Absorption chillers utilize thermal energy (typically steam or combustion source) in an absorption cyclewith either an ammonia-water or water-lithium bromide solution to produce chilled water.Overall SystemFigure 4.2.2 shows a simple representation of a dual chiller application with all the major auxiliaryequipment. An estimated 86% of chillers are applied in multiple chiller arrangements like that shown inthe figure (Bitondo and Tozzi, 1999). In chilled water systems, return water from the building is circulatedthrough each chiller evaporator where it is cooled to an acceptable temperature (typically 4 to 7°C)(39 to 45°F). The chilled water is then distributed to water-to-air heat exchangers spread throughout thefacility. In these heat exchangers, air is cooled and dehumidified by the cold water. During the process,the chilled water increases in temperature and must be returned to the chiller(s).The chillers shown in Figure 4.2.2 are water-cooled chillers. Water is circulated through the condenserof each chiller where it absorbs heat energy rejected from the high pressure refrigerant. The water isthen pumped to a cooling tower where the water is cooled through an evaporation process. C...