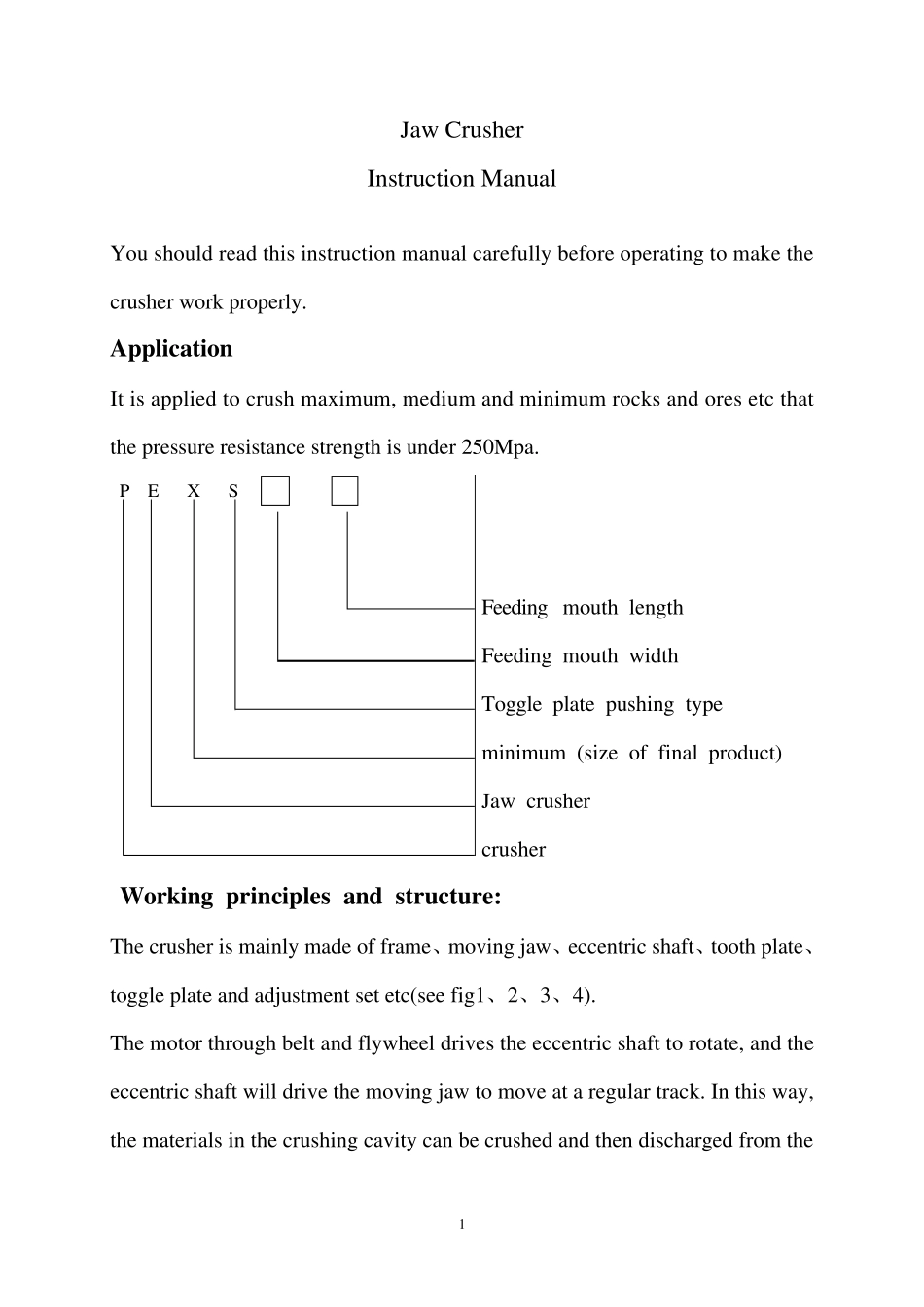

1 Jaw Crusher Instruction Manual You should read this instruction manual carefully before operating to make the crusher work properly. Application It is applied to crush maximum, medium and minimum rocks and ores etc that the pressure resistance strength is under 250Mpa. P E X S Feeding mouth length Feeding mouth width Toggle plate pushing type minimum (size of final product) Jaw crusher crusher Working principles and stru ctu re: The crusher is mainly made of frame、moving jaw、eccentric shaft、tooth plate、toggle plate and adjustment set etc(see fig1、2、3、4). The motor through belt and flywheel drives the eccentric shaft to rotate, and the eccentric shaft will drive the moving jaw to move at a regular track. In this way, the materials in the crushing cavity can be crushed and then discharged from the 2 discharge opening. Frame: we have two kinds of frame, one is jointing, and another one is steel cast. The fixed jaw plate fastened by wedge-shaped check plate is installed to the front of the frame. The upper and lower cheek plates are installed at the right and left side of the frame to protect wall of the frame. Moving jaw : As showed as fig 2、5, the moving jaw is made of cast steel, movable jaw plate is fastened to the front of the moving jaw by bolt. Assembly consisting of bearing, cover, eccentric shaft is installed to the upper part of it. The lower part of it is connected with frame through toggle plate, drawback rod and spring etc. Toggle plate: it is made of accurate cast iron. It is installed in middle of the adjust base and mainframe. It’s not only the component that spreads the strength, but also the insurance part of the crusher. The toggle plate will broke u...