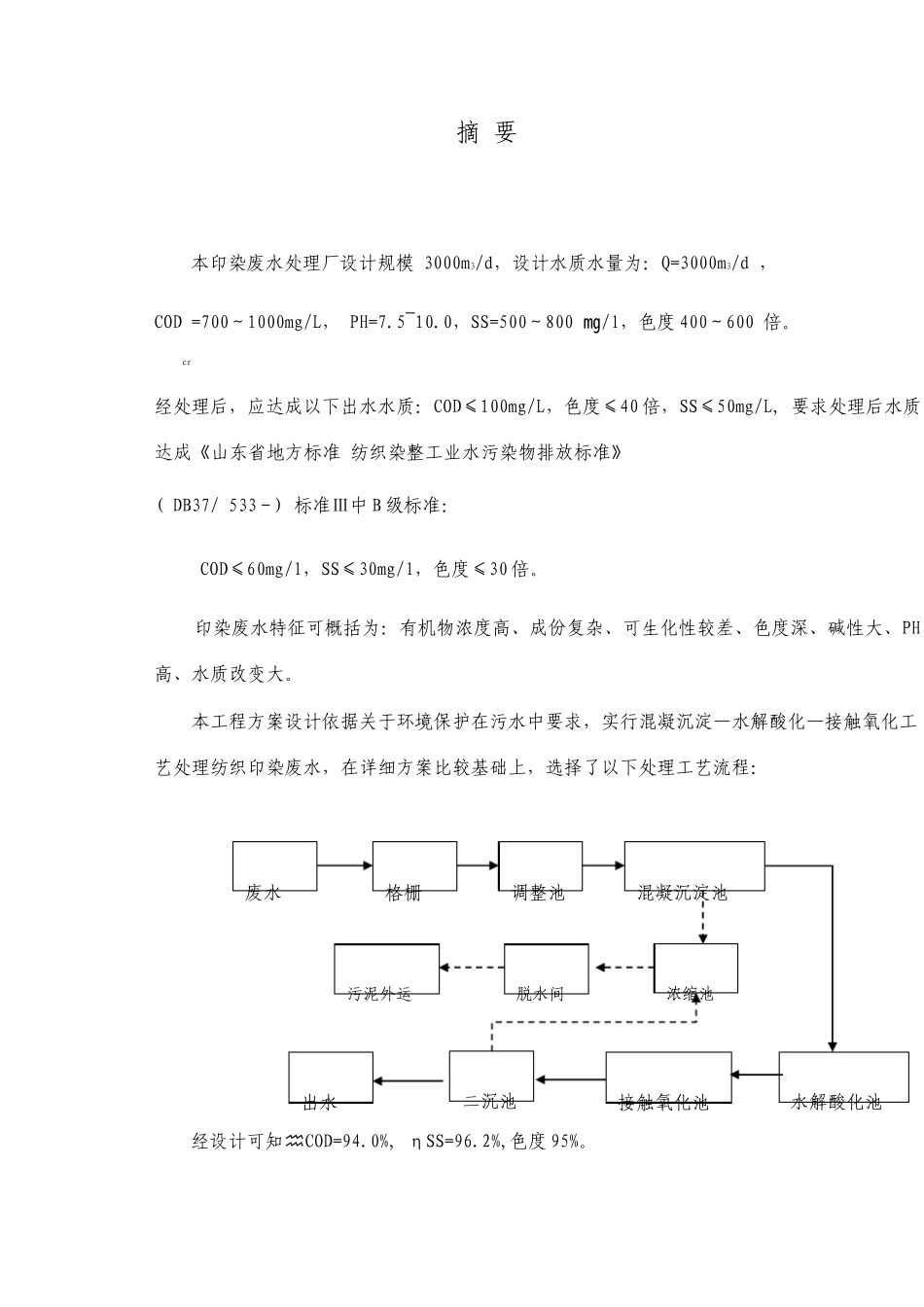

摘 要 本印染废水处理厂设计规模 3000m3/d,设计水质水量为:Q=3000m3/d ,COD =700~1000mg/L, PH=7.5~10.0,SS=500~800 ㎎/l,色度 400~600 倍。cr经处理后,应达成以下出水水质:COD≤100mg/L,色度≤40 倍,SS≤50mg/L, 要求处理后水质达成《山东省地方标准 纺织染整工业水污染物排放标准》 ( DB37/ 533-) 标准Ⅲ中 B 级标准: COD≤60mg/l,SS≤30mg/l,色度≤30 倍。 印染废水特征可概括为:有机物浓度高、成份复杂、可生化性较差、色度深、碱性大、PH 高、水质改变大。 本工程方案设计依据关于环境保护在污水中要求,实行混凝沉淀—水解酸化—接触氧化工艺处理纺织印染废水,在详细方案比较基础上,选择了以下处理工艺流程: 经设计可知COD=94.0%, ηSS=96.2%,色度 95%。 废水 调整池 格栅 混凝沉淀池 水解酸化池 接触氧化池 二沉池 出水 浓缩池 脱水间 污泥外运 经技术经济分析,此方案投资总额 869 万元,废水处理成本为 2.8 元/ m3。 关键词: 纺织印染废水 混凝 水解酸化 接触氧化 Abstract The designing scale of waste water treatment plant is3000 m3/d, the designing quality and quantity of water are: Q=3000m3/d ,COD=700 ~1000mg/L ,PH=7.5~10 ,SS=500~800 ㎎/l ,Color degree=400~600 times. After disposing of it, the quality of water should attain the following standards: COD≤60mg/L,SS≤30mg/L,Chroma ≤ 30 times,reaching the B standard of (DB37/533-)of local standards of Shandong Province Textile industrial water pollutant discharge standards. The design of this project is in accordance with requirements of the environmental protection in the wastewater. It uses the coagulation- sedimentation -hydrolytic acidificati contact oxidation process to deal with the– wastewater in textile printing. Based on comparison of the detailed program, we select the following processes: Through designing, we can know that the resultCOD is 94of %,ηSS is 96.2%,color degree is 95%. After technical and economic analyzing, the investment amount of this p...