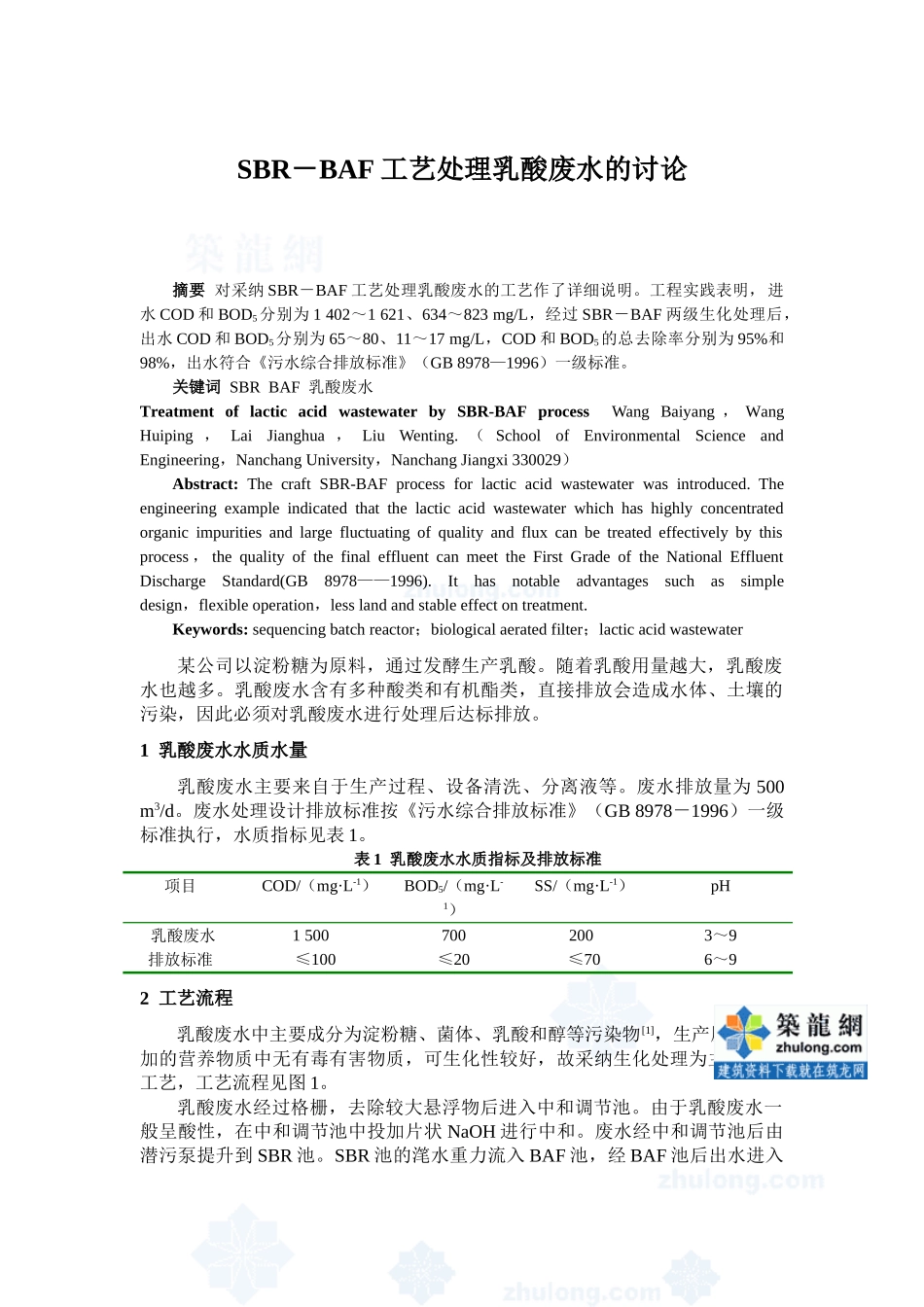

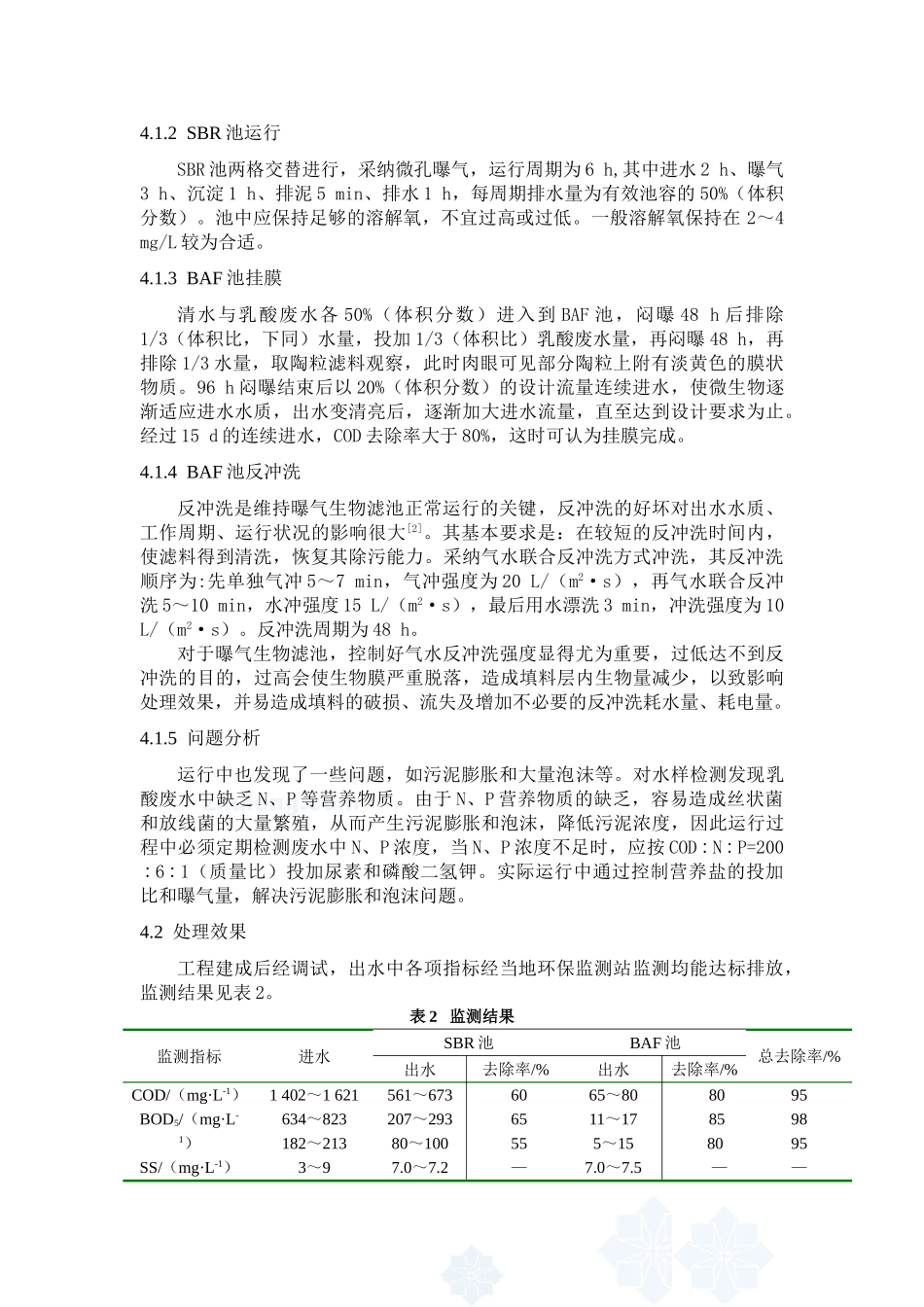

SBR-BAF 工艺处理乳酸废水的讨论摘要 对采纳 SBR-BAF 工艺处理乳酸废水的工艺作了详细说明。工程实践表明,进水 COD 和 BOD5分别为 1 402~1 621、634~823 mg/L,经过 SBR-BAF 两级生化处理后,出水 COD 和 BOD5分别为 65~80、11~17 mg/L,COD 和 BOD5的总去除率分别为 95%和98%,出水符合《污水综合排放标准》(GB 8978—1996)一级标准。关键词 SBR BAF 乳酸废水Treatment of lactic acid wastewater by SBR-BAF process Wang Baiyang , Wang Huiping , Lai Jianghua , Liu Wenting. ( School of Environmental Science and Engineering,Nanchang University,Nanchang Jiangxi 330029)Abstract: The craft SBR-BAF process for lactic acid wastewater was introduced. The engineering example indicated that the lactic acid wastewater which has highly concentrated organic impurities and large fluctuating of quality and flux can be treated effectively by this process , the quality of the final effluent can meet the First Grade of the National Effluent Discharge Standard(GB 8978——1996). It has notable advantages such as simple design,flexible operation,less land and stable effect on treatment.Keywords: sequencing batch reactor;biological aerated filter;lactic acid wastewater某公司以淀粉糖为原料,通过发酵生产乳酸。随着乳酸用量越大,乳酸废水也越多。乳酸废水含有多种酸类和有机酯类,直接排放会造成水体、土壤的污染,因此必须对乳酸废水进行处理后达标排放。1 乳酸废水水质水量乳酸废水主要来自于生产过程、设备清洗、分离液等。废水排放量为 500 m3/d。废水处理设计排放标准按《污水综合排放标准》(GB 8978-1996)一级标准执行,水质指标见表 1。 表 1 乳酸废水水质指标及排放标准项目COD/(mg·L-1)BOD5/(mg·L-1)SS/(mg·L-1)pH乳酸废水排放标准1 500≤100700≤20200≤703~96~92 工艺流程乳酸废水中主要成分为淀粉糖、菌体、乳酸和醇等污染物[1],生产原料和投加的营养物质中无有毒有害物质,可生化性较好,故采纳生化处理为主的处理工艺,工艺流程见图 1。乳酸废水经过格栅,去除较大悬浮物后进入中和调...