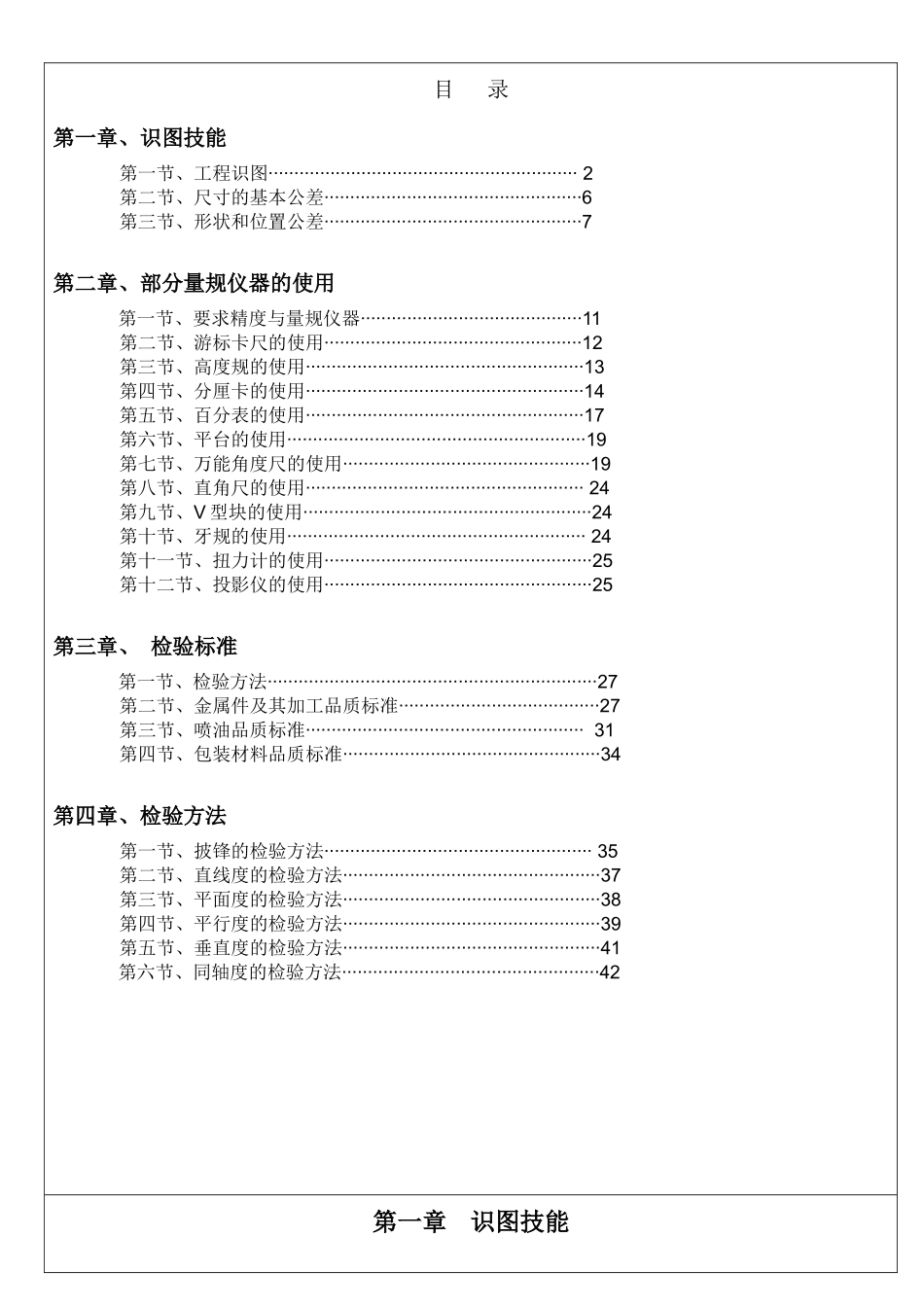

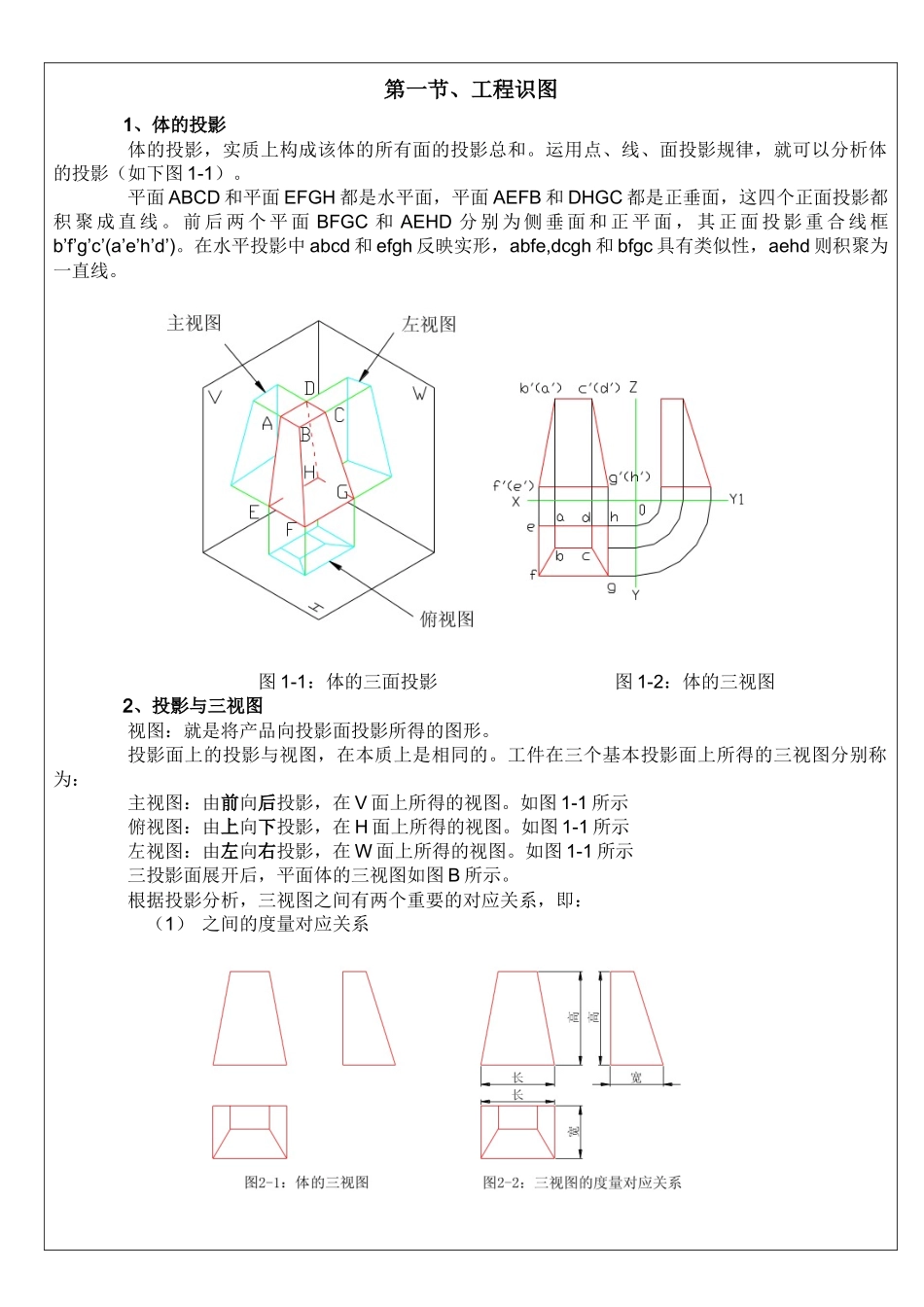

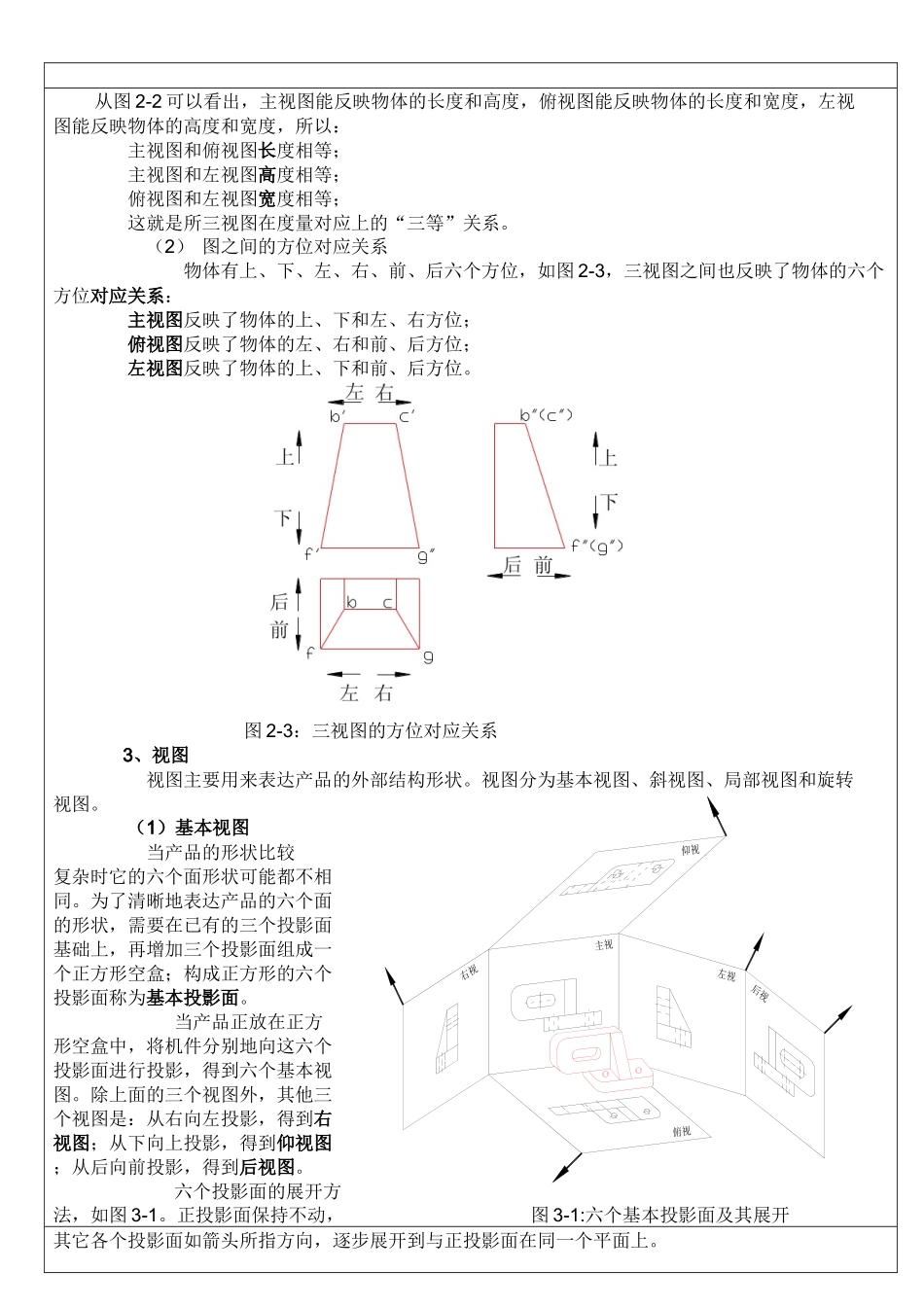

目录第一章、识图技能第一节、工程识图····························································2第二节、尺寸的基本公差··················································6第三节、形状和位置公差··················································7第二章、部分量规仪器的使用第一节、要求精度与量规仪器···········································11第二节、游标卡尺的使用··················································12第三节、高度规的使用······················································13第四节、分厘卡的使用······················································14第五节、百分表的使用······················································17第六节、平台的使用··························································19第七节、万能角度尺的使用················································19第八节、直角尺的使用······················································24第九节、V型块的使用························································24第十节、牙规的使用··························································24第十一节、扭力计的使用····················································25第十二节、投影仪的使用····················································25第三章、检验标准第一节、检验方法································································27第二节、金属件及其加工品质标准·······································27第三节、喷油品质标准······················································31第四节、包装材料品质标准··················································34第四章、检验方法第一节、披锋的检验方法····················································35第二节、直线度的检验方法··················································37第三节、平面度的检验方法··················································38第四节、平行度的检验方法··················································39第五节、垂直度的检验方法··················································41第六节、同轴度的检验方法··················································42第一章识图技能第一节、工程识图1、体的投影体的投影,实质上...