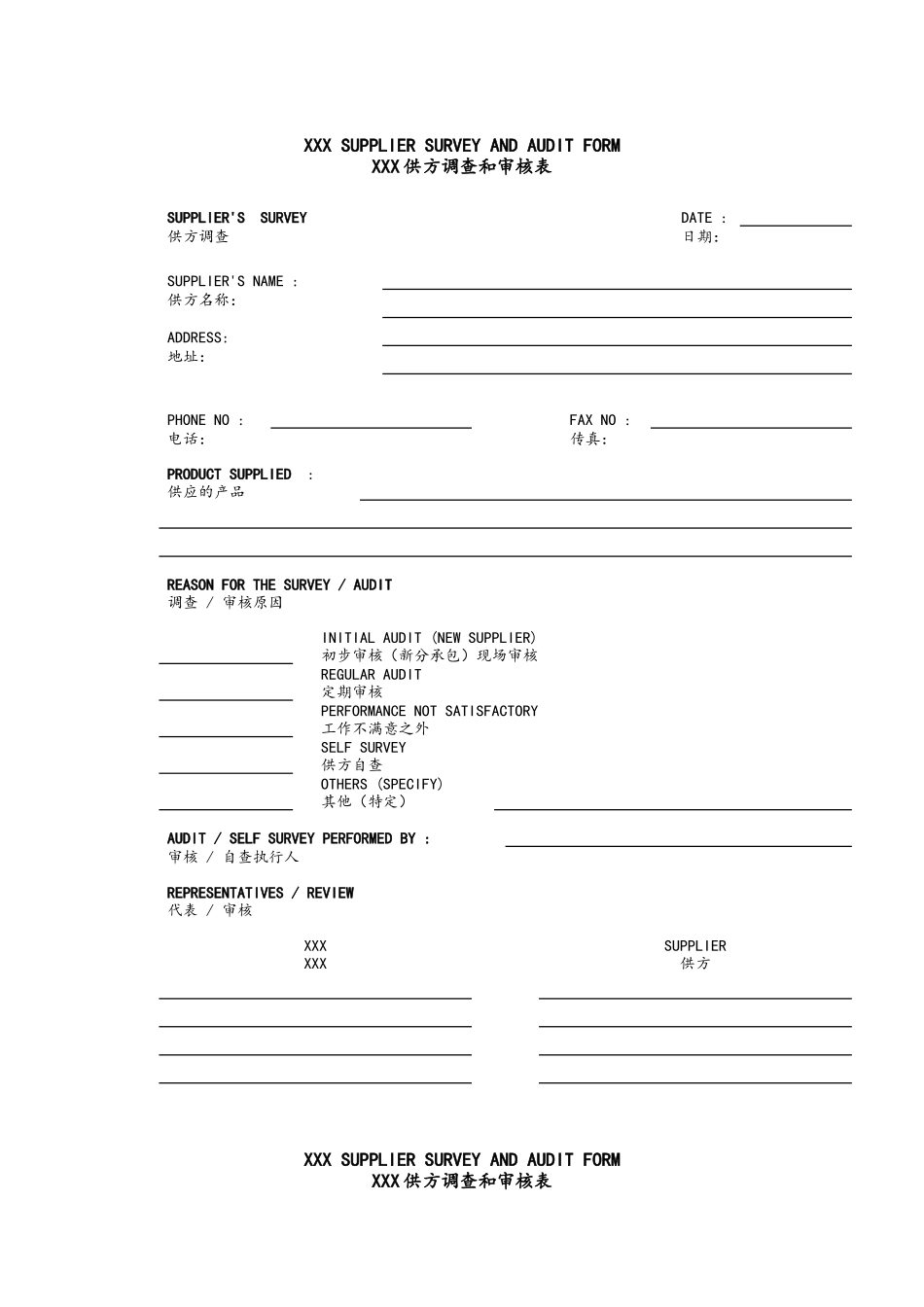

XXXSUPPLIERSURVEYANDAUDITFORMXXX供方调查和审核表SUPPLIER'SSURVEYDATE:供方调查日期:SUPPLIER'SNAME:供方名称:ADDRESS:地址:PHONENO:FAXNO:电话:传真:PRODUCTSUPPLIED:供应的产品REASONFORTHESURVEY/AUDIT调查/审核原因INITIALAUDIT(NEWSUPPLIER)初步审核(新分承包)现场审核REGULARAUDIT定期审核PERFORMANCENOTSATISFACTORY工作不满意之外SELFSURVEY供方自查OTHERS(SPECIFY)其他(特定)AUDIT/SELFSURVEYPERFORMEDBY:审核/自查执行人REPRESENTATIVES/REVIEW代表/审核XXXSUPPLIERXXX供方XXXSUPPLIERSURVEYANDAUDITFORMXXX供方调查和审核表ASSESSMENTAREAActualRating评估内容PointsPoints1.组织机构2.采购控制3.进货材料4.不合格品控制(过程中和最后出货)5.生产线控制6.SPC7.在线检验8.校验9.设备维护10.文件和图纸控制11.最终产品检验12.包装和发货13.培训和教育14.清洁、搬运、储存TOTALOVERALLRATING%总得分比率FINALOUTSTANDING(ABOVE90%)SATISFACTORY(75%-90%)优异满意RATINGNEEDIMPROVEMENT(60%-74.9%)POOR(BELOW60%)需改进不合格(低于60%)RATINGSCALEPOINTINTERPRETATION说明4-OUTSTANDING优异的3-SATISFACTORY满意2-NEEDIMPROVEMENT需改进1-SIGNIFICANTDEFICIENCY重大缺陷0-NOSYSTEM无系统XXXSUPPLIERSURVEYANDAUDITFORMXXX供方调查和审核表REQUESTFORCORRECTIVEACTION纠正措施申请单SupplierresponseDUEDATE:供方回复到期日:2003.11.30(将回复传回XXX的日期)Supplierresponseby:供方回复人:Title:职位AuditFindings审核发现SupplierActionPlan供方纠正措施计划CompleteDate预定完成日期需改进事项1模治具的管理没有系统化(如:标识管理、定期校验、建立履历档案等)2张力等在制程中有变化的过程参数,没有建立监控的方式。3用于指导过程工艺指导的文件不在现场不宜为使用人员获得。4原料供方质量重大异常问题的纠正措施的及时性、有效性无系统的跟催。建议改进事项1对料片宽度在制程中的稳定性,建议采用SPC的方法(如:X-R图)进行控制。2对生产现场的一线员工(如:操作员、调试技术人员)进行常规的培训,以提升其综合素质。CORRECTIVEACTIONVERIFICATION纠正措施效果确认(由XXX稽核员填写)XXXSUPPLIERSURVEYANDAUDITFORMXXX供应商调查和审核表EVALUATIONRESULT评估结果GENERALCOMMENTS:概述:XXXSUPPLIERSURVEYANDAUDITFORMXXX供方调查和审核表Question(问题)RatingScore(评分)01234N/AAQUALITYORGANIZATION组织机构1.TheQAorganization’sresponsibilitiesandactivitiesareclearlydefinedinwritingandhaveclearauthoritytowithholditemsthathavenotmetacceptablequalitystandards.是否将QA部门的职责和权力书面定义,对不符合质量要求的项目是否有中止生产的权力2.ThereisQAmanualandasystemforcontinualupdateandmaintenance.是否有持续更改的质量手册或系统3.TheQAorganizationoperXXXadefectpreventionprogramandhadinvestedresourcesincontinuouslyimprovingqualityperformanceQA部门是否运行预防系统以持续改进质量状况4.TheQAorganizationpreparesandissuesperiodicreportsandmaintainsrecordsrelativetoprocesscontrolyields,topqualityproblemsandcustomercomplaintsstatus,PPMperformanceandothersQA部门是否发出周期性质量报告,包括合格率,质量问题,客户投诉,缺陷分析等。5.Majorchange,includingmaterialandprocesschange,getcustomerapprovalbeforeimplementation.重大更改,包括材料和工艺,在执行前是否通知客户,取得批准。6.Thereisawelldefinedsystemforreplyingcustomercomplaint,andhavetheabilitytocommunicatenecessaryinformationanddatainthecustomer-prescribedformat.是否有良好系统处理客户投诉,并以客户规定的格式进行沟通。7.TheQAorganizationmaintainsasystemfortheuseandcontrolofinspectionstamps.QA部门是否控制检验印章。8.ThereisplanineffecttobecomeregisteredinISO.Ifyesindicatetimetable:是否有计划通过ISO,请附上时间表:Totalscore(得分)outof(总分)COMMENTS:评注:第6页共14页编号:...