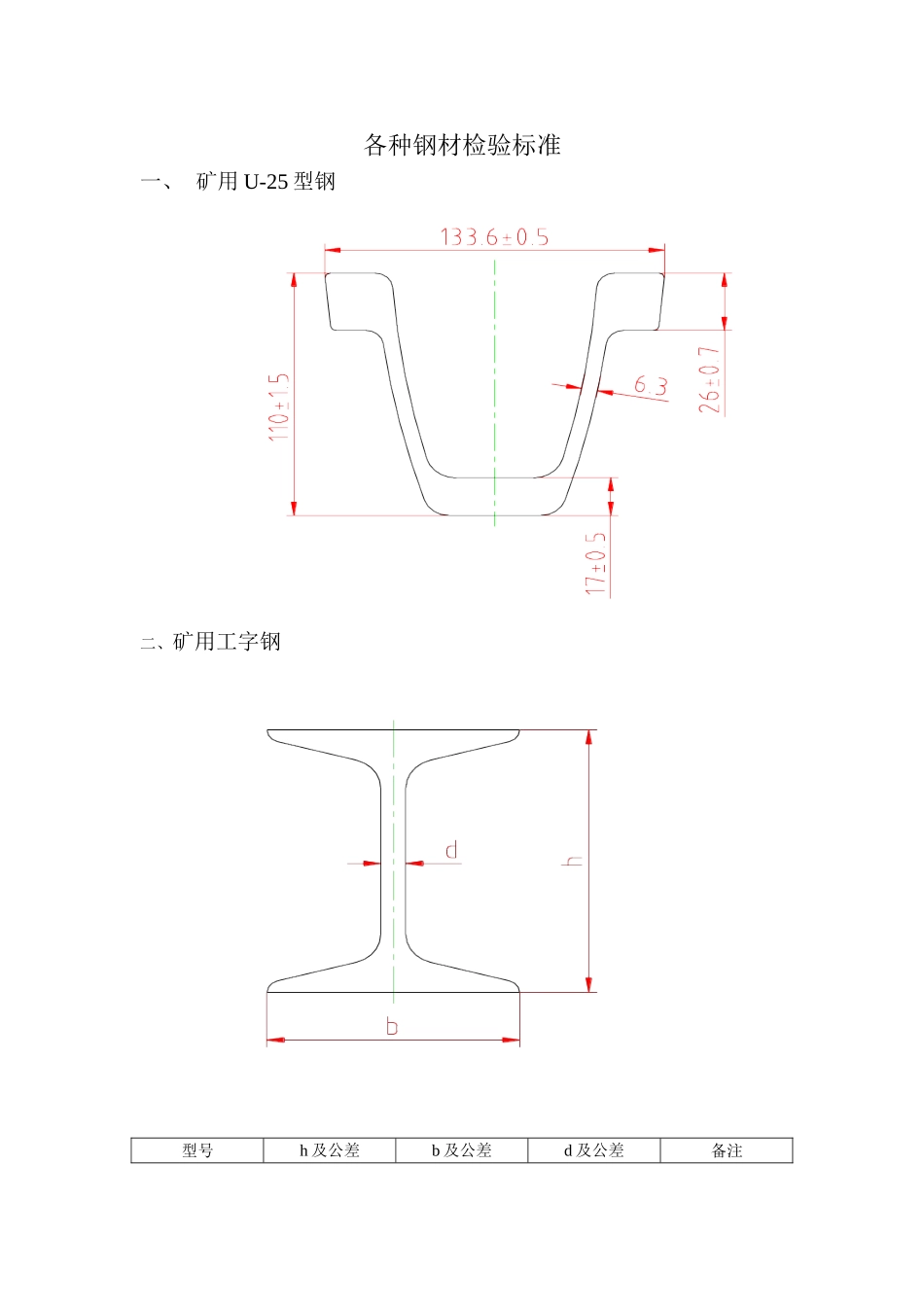

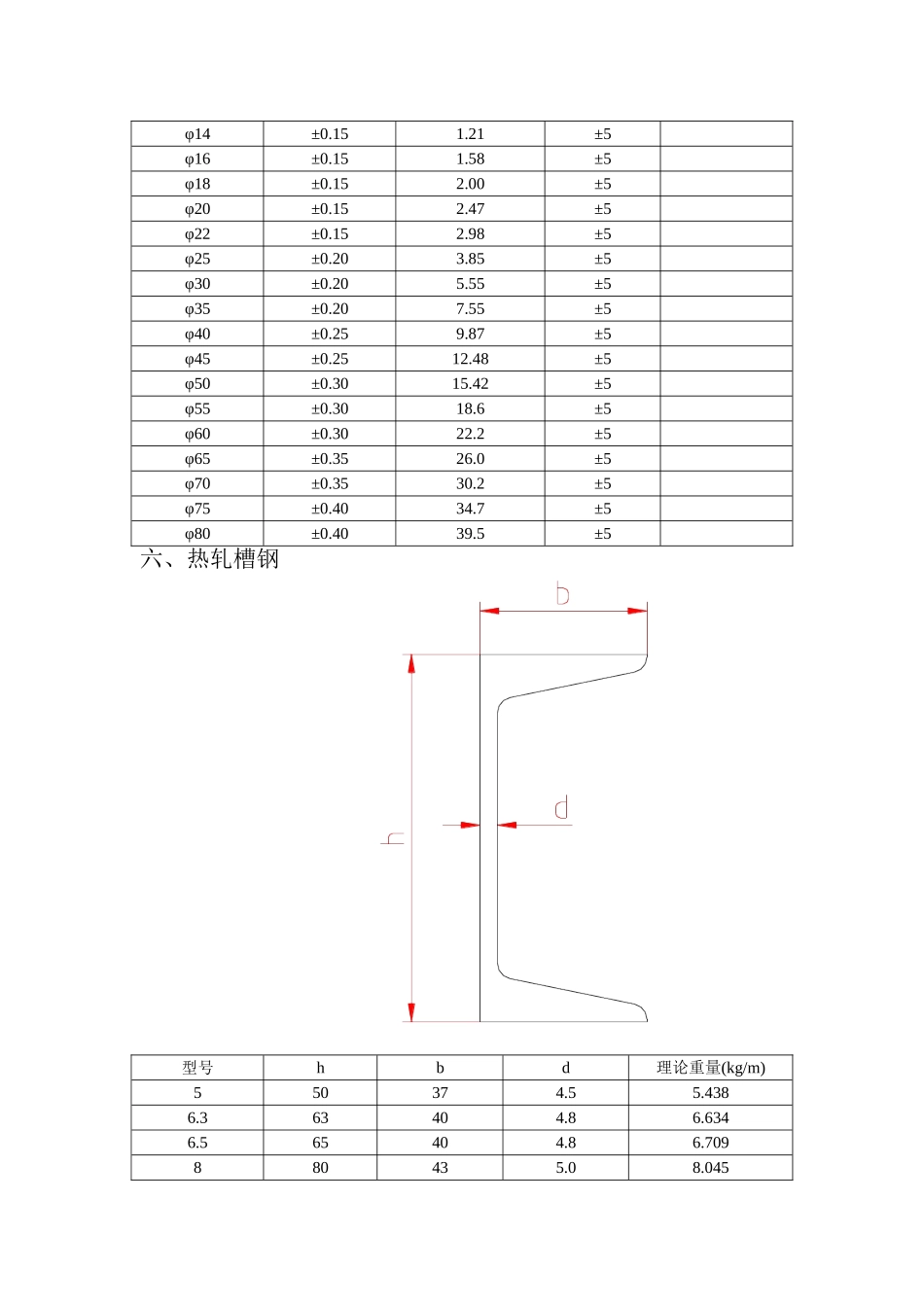

各种钢材检验标准一、矿用U-25型钢二、矿用工字钢型号h及公差b及公差d及公差备注990±1.576±28±0.311110±1.590±29±0.312120±1.595±211±0.3三、矿用轻轨轻轨类型(kg/m)ABCD理论重量(kg/m)1180.566327.011.2159176377.014.72189080401018.062224107925110.924.46四、钢板钢板型号厚度公差理论重量(kg/m2)长度及公差备注3±0.1023.55±34±0.1031.40±35±0.1539.25±36±0.1547.10±38±0.2062.80±310±0.2078.50±312±0.2594.20±316±0.30125.6±320±0.30157.0±325±0.35196.30±3五、圆钢圆钢型号直径公差理论重量(kg/m)长度公差备注φ5.5±0.100.186±5φ8±0.100.395±5φ10±0.100.617±5φ12±0.100.888±5φ14±0.151.21±5φ16±0.151.58±5φ18±0.152.00±5φ20±0.152.47±5φ22±0.152.98±5φ25±0.203.85±5φ30±0.205.55±5φ35±0.207.55±5φ40±0.259.87±5φ45±0.2512.48±5φ50±0.3015.42±5φ55±0.3018.6±5φ60±0.3022.2±5φ65±0.3526.0±5φ70±0.3530.2±5φ75±0.4034.7±5φ80±0.4039.5±5六、热轧槽钢型号hbd理论重量(kg/m)550374.55.4386.363404.86.6346.565404.86.709880435.08.04510100485.310.00712120535.512.05912.6126535.512.31814a140586.014.53514b140608.016.73316a160636.517.24016b160658.519.75218a180687.020.17418180709.023.00020a200737.022.63720200759.025.77722a220777.024.99922220799.028.45324a240787.026.86024b240809.030.62824c2408211.034.39625a250787.027.41025b250809.031.33525c2508211.035.260七、热轧等边角钢型号bd理论重量(kg/m)220340.8891.1452.525341.1241.45933031.37341.7863.6363451.6562.1632.6544403451.8522.4222.9764.54534562.0882.7363.3693.98555034562.3323.0593.7704.4655.65634582.6243.4464.2516.5866.3634568103.9074.8225.7217.4699.151770456784.3725.3976.4067.3988.3737.5755678105.8186.9057.9769.08011.0898805678106.2117.3768.5259.68511.874990678108.3509.65610.94613.4761215.94010100678101214169.36610.83012.27615.12017.89820.61123.257111107810121411.92813.53216.69019.78222.80912.5125810121415.50419.13322.69626.193141401012141621.48825.52229.49033.393161601012141624.72929.39133.98738.518181801214161833.15938.38343.54248.634八、低压液体输送用焊接钢管及镀锌焊接钢管公称口径外径普通钢管加厚钢管(mm)(in)公称尺寸壁厚(mm)理论重量(kg/m)壁厚(mm)理论重量(kg/m)61/810.02.000.392.500.4681/413.52.250.622.750.73103/817.02.250.822.750.73151/221.32.751.263.251.45203/426.82.751.633.502.0125133.53.252.424.002.913211/442.33.253.134.003.784011/248.03.503.844.254.5850260.03.54.884.56.166521/275.53.756.644.57.8880388.54.008.344.759.8110041144.0010.855.0013.441255140.04.5015.045.5018.2415061654.5017.815.5021.63九、钢丝绳6×19(a)类圆股钢丝绳:钢丝绳公称直径d(mm)钢丝绳近似重量(kg/100m)备注天然纤维芯合成纤维芯钢芯613.3013.0014.60718.1017.6019.90823.6023.0025.90929.9029.1032.801036.9036.0040.5012.554.1215.584.5718.5121.821.5165.824.5216.52526249.00243.00274.0028289.00282.00318.00十、矿用电缆芯数×导体标称截面(mm2)标称厚度(mm2)电缆外径(mm2)动力线芯地线芯动力线芯绝缘护套MY-0.38/0.66MYP-0.38/0.663×41×41.43.520.9-23.022.9-25.23×61×61.43.522.9-25.124.7-27.23×101×101.64.027.8-30.629.7-32.73×161×101.64.030.3-33.332.2-35.43×251×161.84.536.4-40.138.3-41.03×351×161.84.540.5-44.642.4-46.63×501×162.05.045.5-50.147.4-51.03×701×252.05.051.5-55.052.4-57.13×951×252.46.062.1-68.1检验说明:1、导体单丝直径应从电缆试样的不同类线芯中各任取5根单丝铜线的平均值。2、标志耐磨性试验,应用浸过水的1团脱脂棉或1块棉布轻轻擦拭制造厂名或商标及绝缘七芯颜色或数字标志,共擦10次后,标志仍保持明显、清晰,方合格。3、标称厚度及电缆外径应取其最小值作为相应的厚度。